Road simulator stand

A technology of road simulation and test bench, which is applied in the field of automobiles, can solve the problems of long test period, inaccurate control of experimental process parameters, inaccurate control of test time, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific embodiments, structures, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

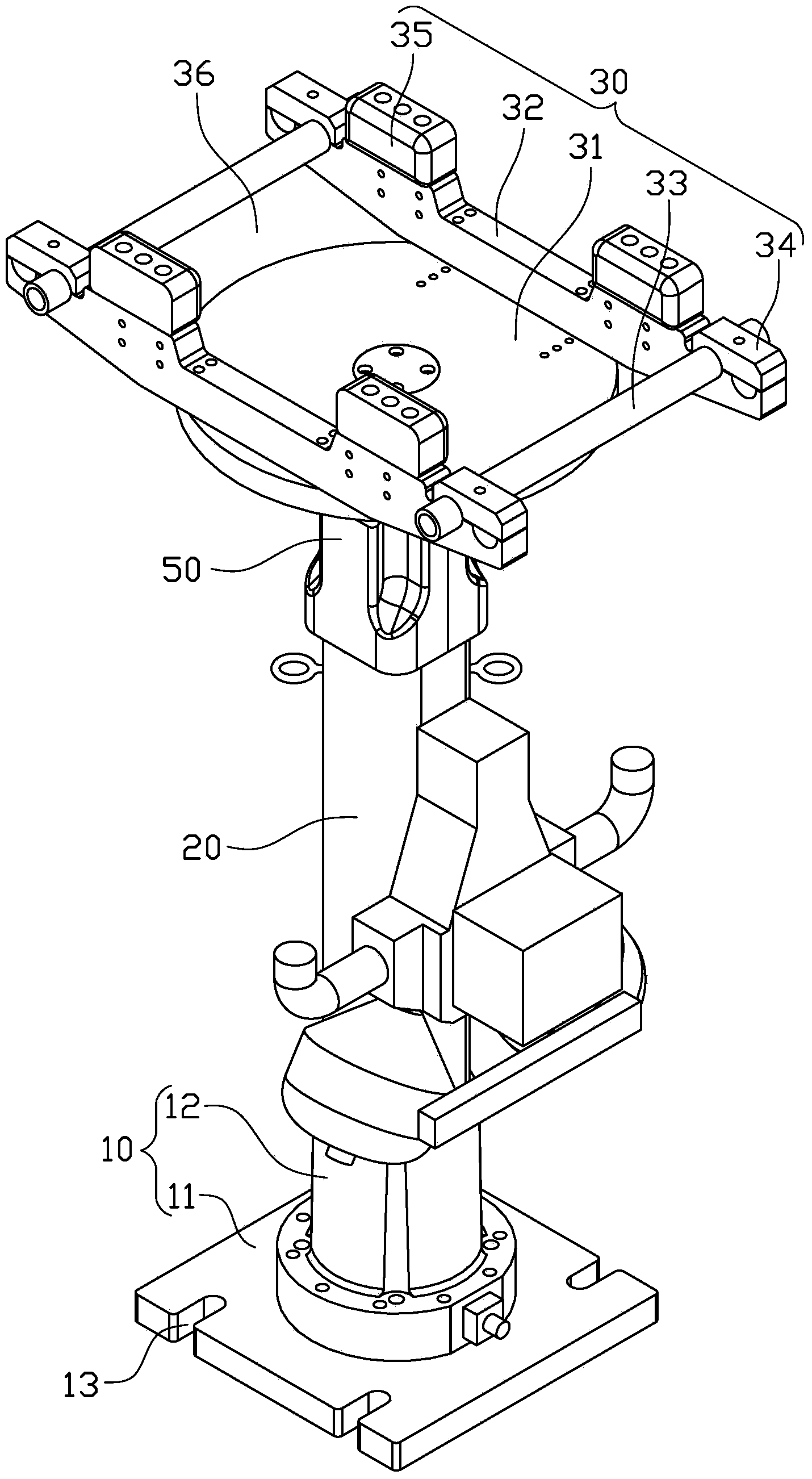

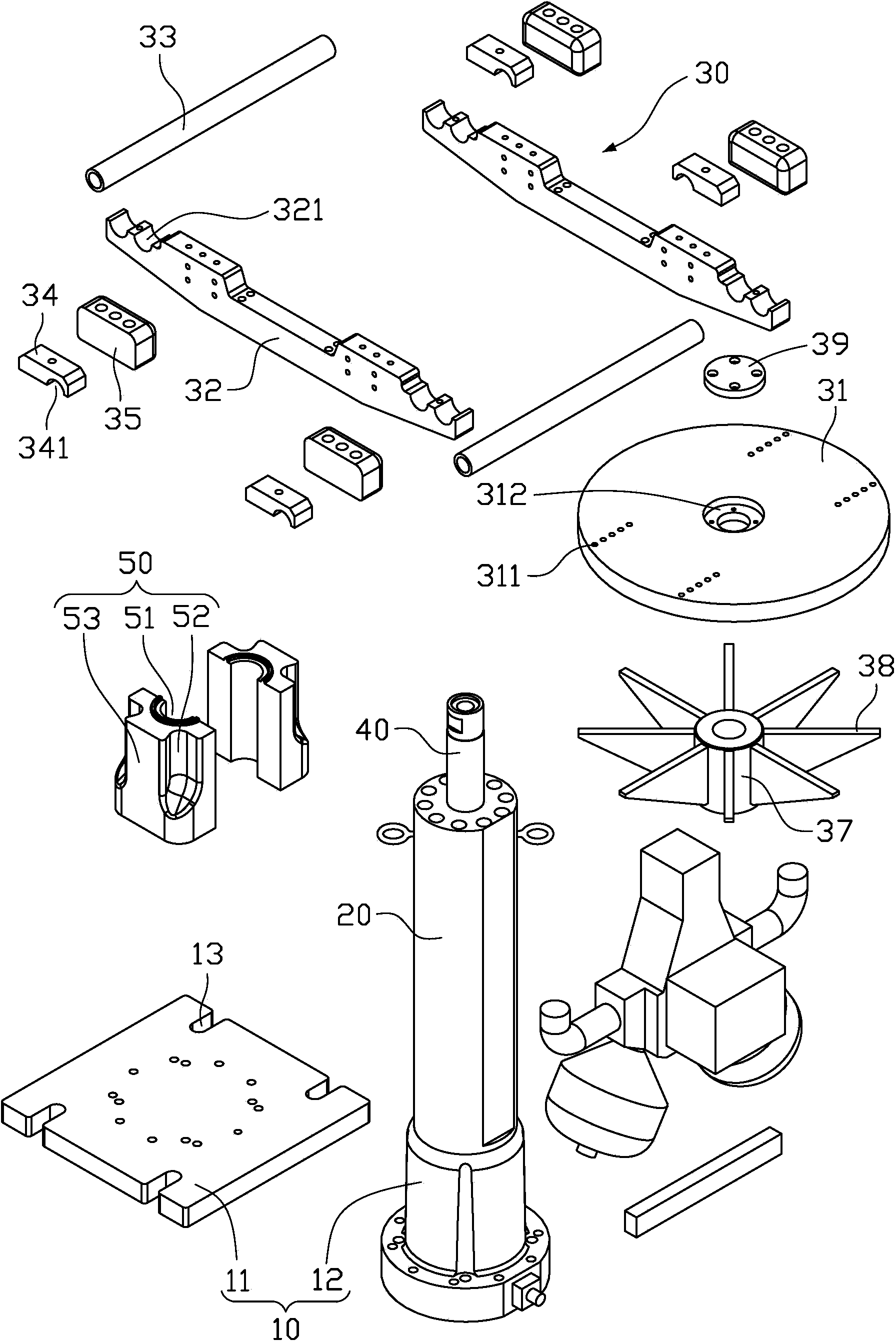

[0019] The road simulation test bench of the present invention is mainly used for the test of simulating the up and down beating of wheels. The road simulation test bench mainly includes several figure 1 The support base 100 is shown. If need utilize the present invention to carry out the uniaxial test of whole vehicle, only need two support bases 100 to support the front wheel of automobile, the rear wheel of automobile adopts other mode to support; If need utilize the present invention to carry out biaxial test of complete vehicle, then need four A supporting base 100 supports the front and rear wheels of the automobile respectively.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com