Base plate, base unit, motor, disk drive apparatus and method of manufacturing base plate

Through the combination of stainless steel and aluminum materials and casting technology, a disk drive device substrate with a high Young's modulus is constructed, which solves the problems of reduced substrate rigidity and increased noise caused by thinning, and achieves more stable disk position and data reading and writing performance. .

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

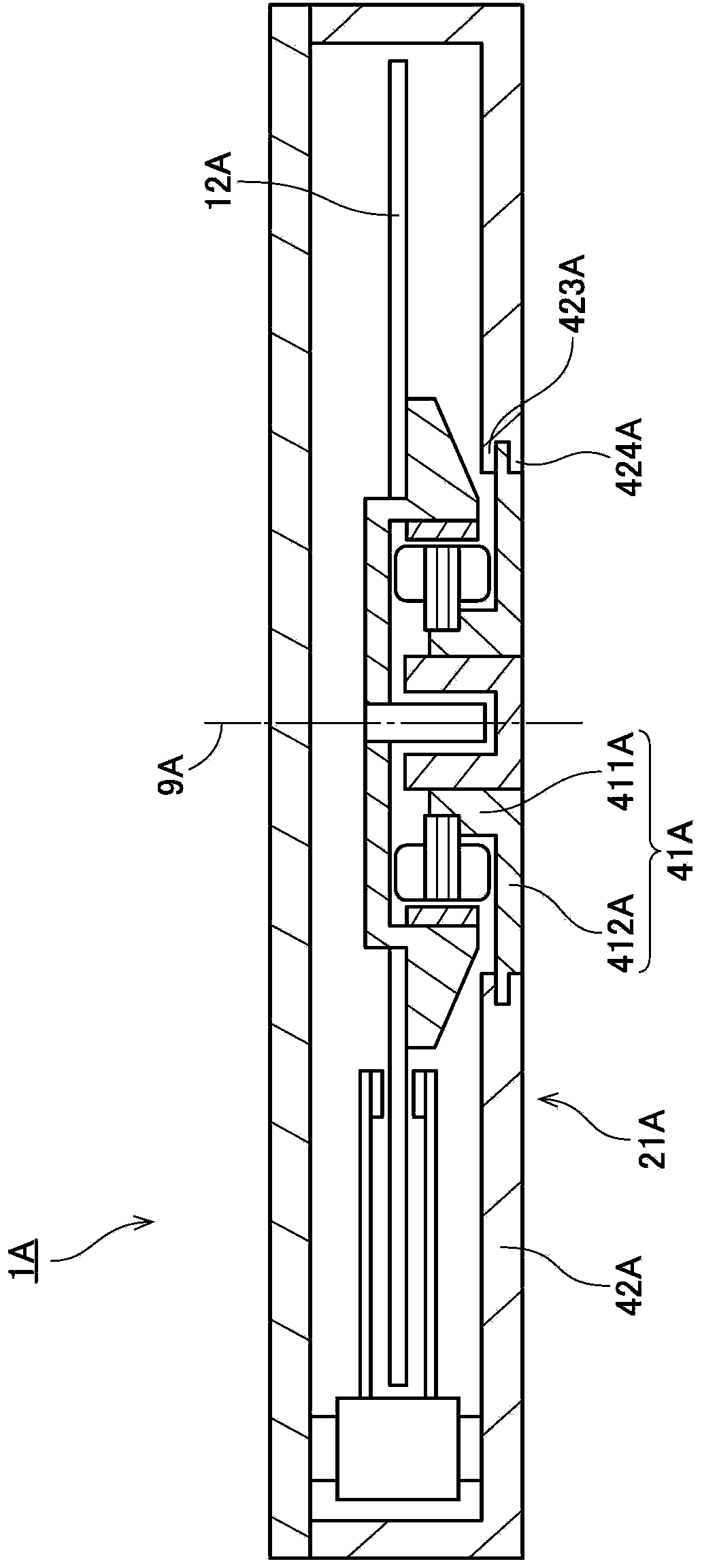

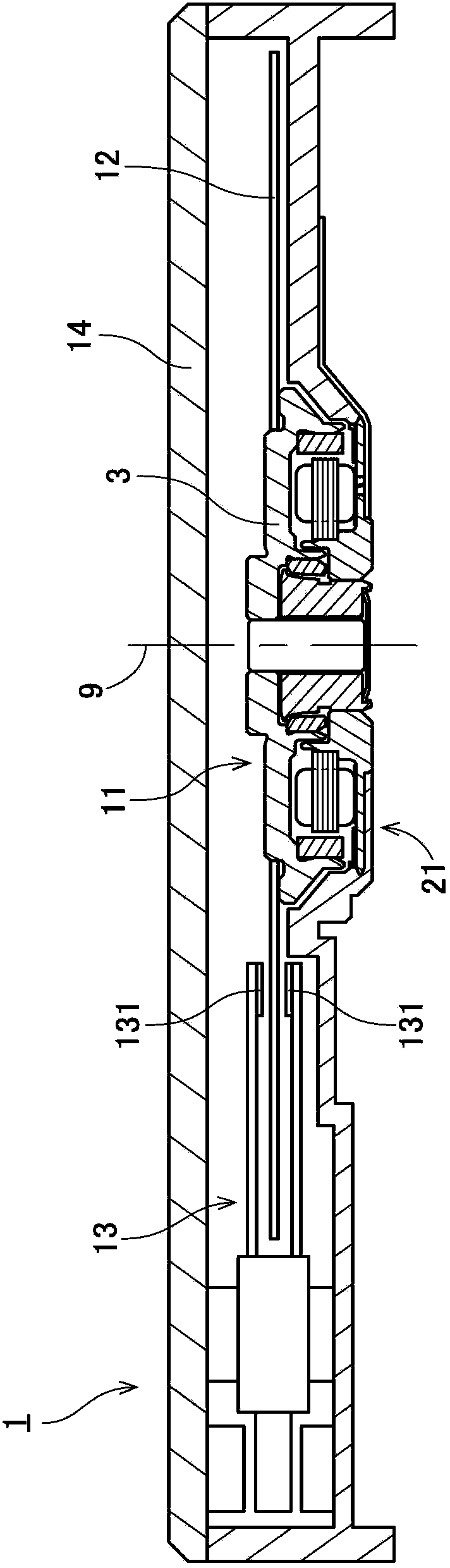

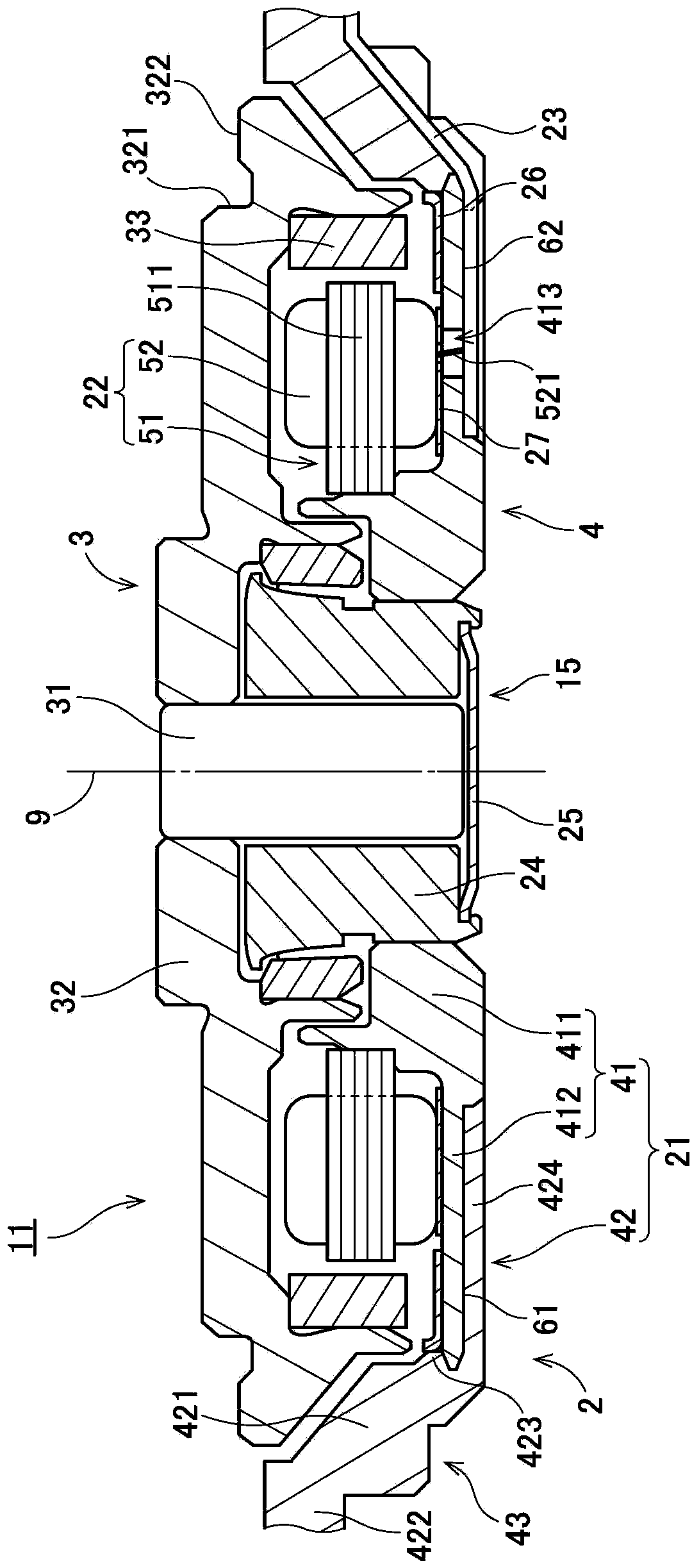

[0029] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. In addition, in this application, the direction parallel to the central axis of the motor is called "axial direction", and the direction perpendicular to the central axis of the motor is called "radial direction". The direction of the arc is called "circumferential". In addition, in the present application, the shape and positional relationship of each part will be described with the axial direction as the up-down direction and the opposing substrate with the stator side as the upward direction. However, the definition of the up-down direction is not intended to limit the directions during manufacture and use of the substrate, base unit, motor, and disk drive device according to preferred embodiments of the present invention.

[0030] Also, the "parallel direction" in the present application includes substantially parallel directions. In addition, the "orthogo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com