Bidirectional torque overload protector

An overload protector and cage technology, applied in the field of machinery, can solve the problems of high manufacturing, maintenance and use costs, complex structure, and large assembly space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] 1. Structure:

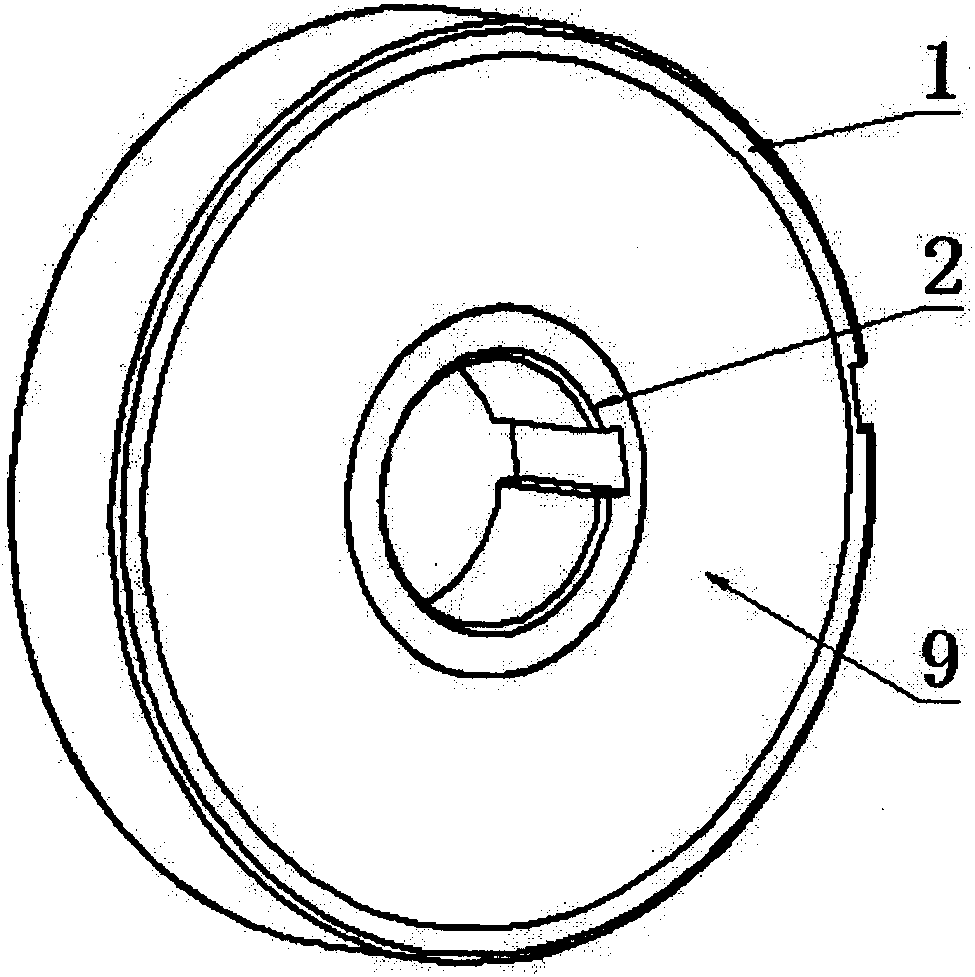

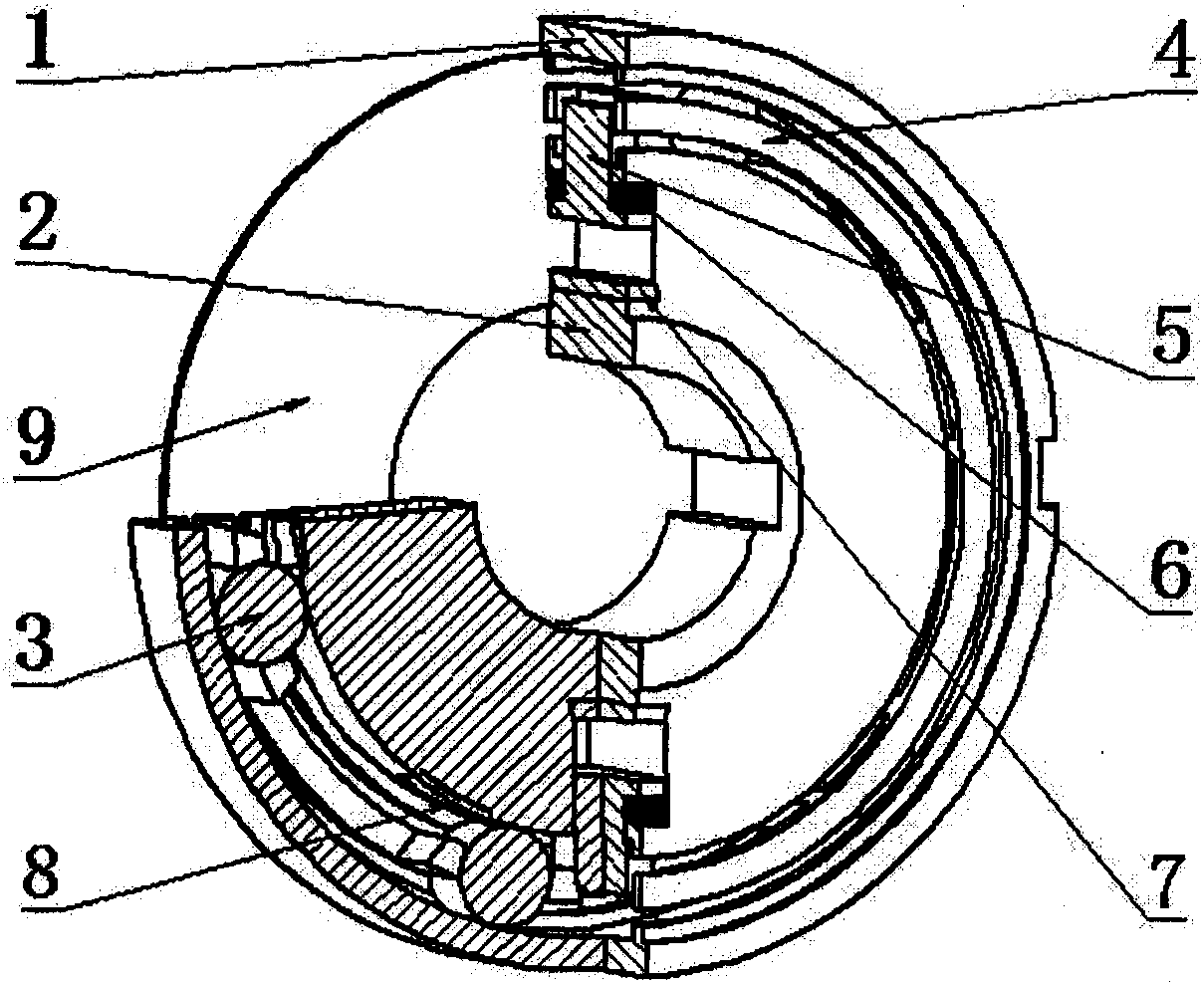

[0014] The two-way torque overload protector consists of an outer ring (1), an inner ring (2), a roller (3), a cage (4), a baffle (5), a serpentine spring (6), a pad (7), a wave spring (8) and end cap (9) constitute.

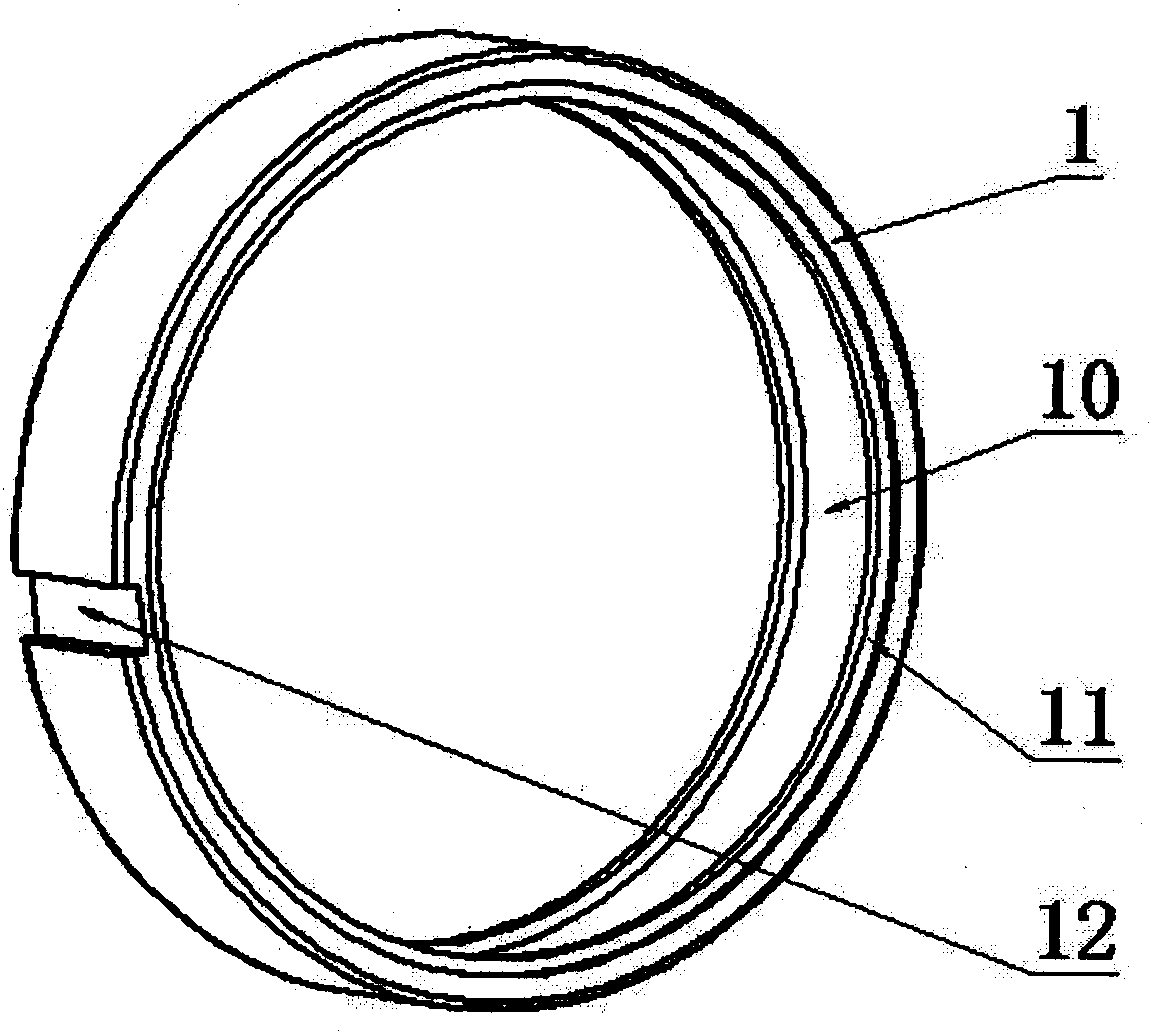

[0015] An outer ring roller groove (10), an outer ring end cover groove (11) and an outer key groove (12) are arranged on the outer ring (1).

[0016] The inner ring (2) has a baffle groove (13), a baffle opening (14), an inner ring roller groove (15), a wave spring groove (16), an inner keyway (17) and an inner ring end cover groove (18 ).

[0017] There are roller holes (19) and baffle holes (20) on the cage.

[0018] Baffle plate (5) is made of baffle plate head (21) and baffle plate ear (22).

[0019] The main structure is composed of outer ring (1), inner ring (2), rollers (3) and cage (4); the outer ring (1) is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com