Structure of slide capable of firstly vibrating pin and then sliding out

A technology of spring needle and row position, which is applied in the field of row position first spring needle and then travel structure, which can solve the problems of inapplicable mold structure and high mold cost, and achieve the effect of cost reduction and simple demoulding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

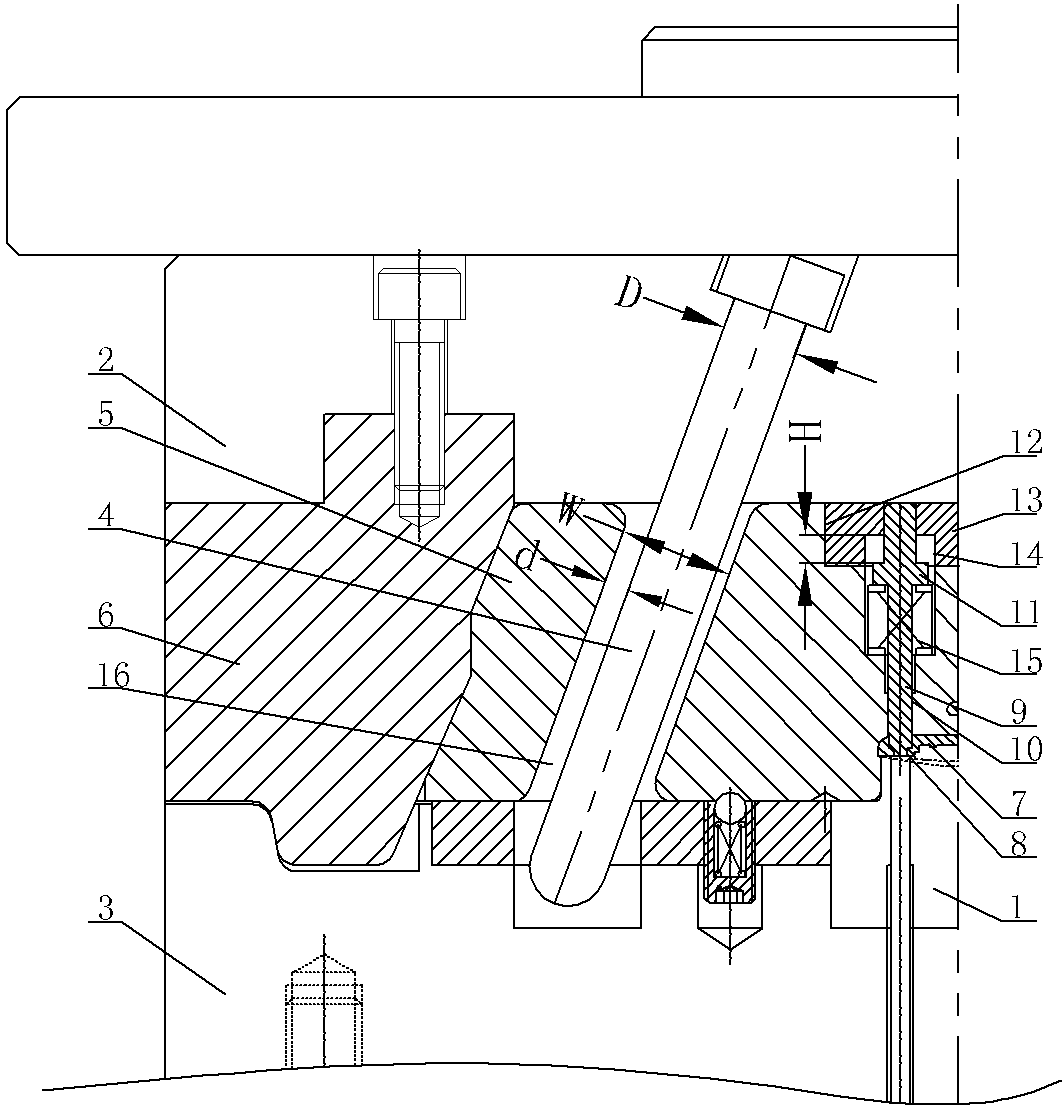

[0008] See figure 1 , which includes the front mold (not shown in the figure, which belongs to the existing mature structure), the rear mold 1, the A plate 2, the B plate 3, the inclined guide post 4, the slider 5, and the front mold and the rear mold 1 are combined to form a cavity 7. The inner side of the slider 5 is close to one side of the cavity 7, and the cavity 7 is provided with a concave hole 8 at the position of the slider 5, and the lower end of the thimble 9 of the front mold insert passes through the installation hole 10 of the slider 2 Deep into the concave hole 8, a protruding block 11 is provided in the middle of the front mold insert thimble 9, and a pressing block installation groove 12 is opened above the mounting hole 10, and the pressing block installation groove 12 is located on the upper surface of the slider 5. The tight block 13 is located in the pressing block installation groove 12, the lower end face of the A plate 2 is pressed against the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com