Integrated lipstick tube preparation mold and preparation process thereof

A lipstick tube and integrated technology, which is applied in the field of an integrated lipstick tube preparation mold and its preparation process, can solve the problems of complex demolding structure, inconvenient operation, inability to realize temperature control, etc., and achieves simple demolding structure and high automation level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

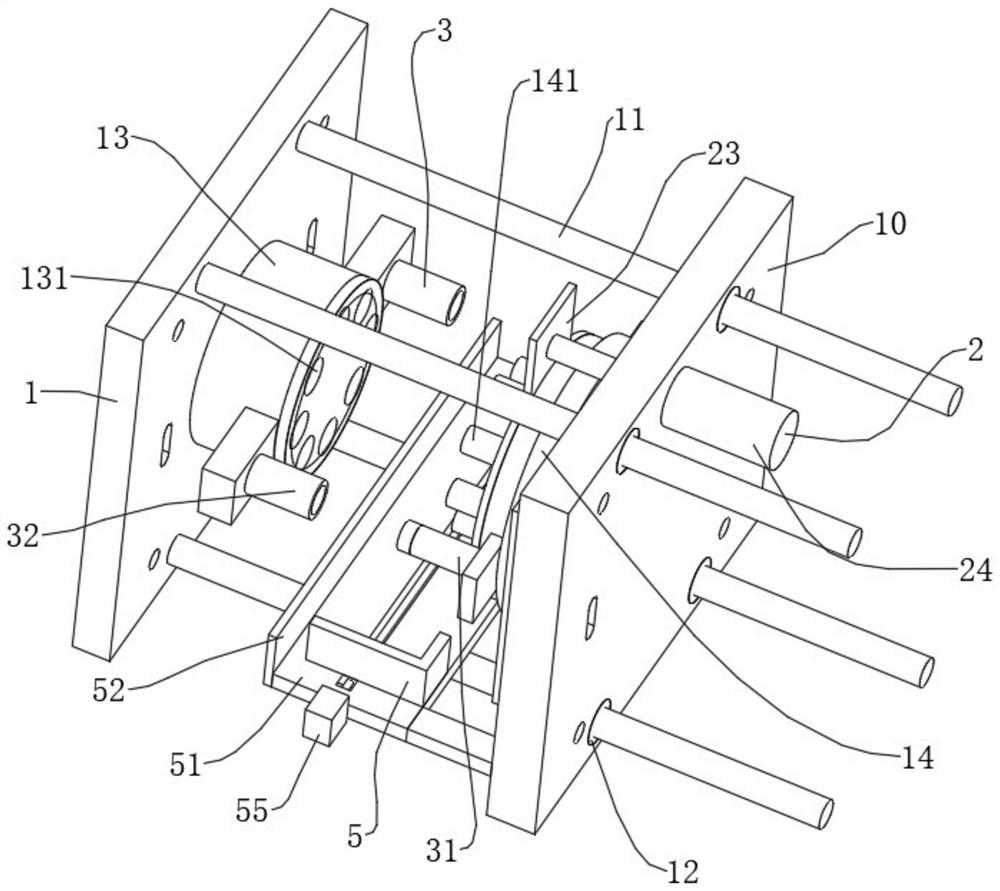

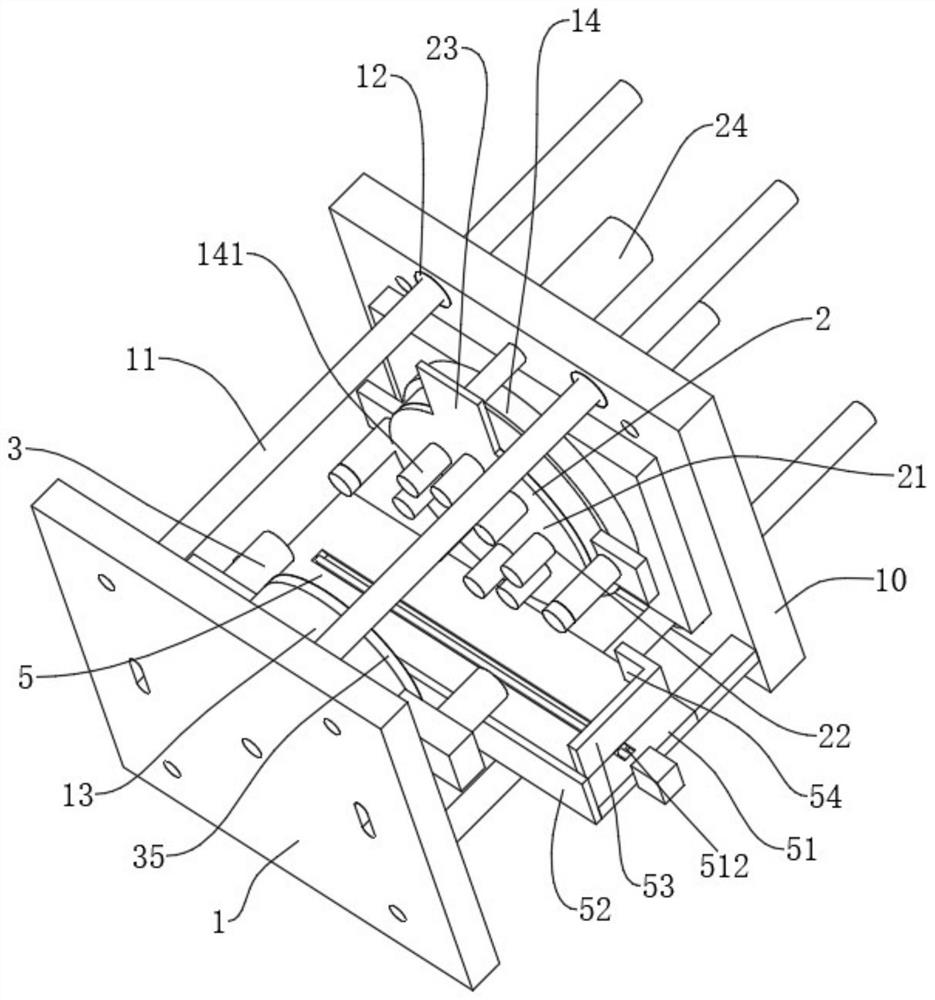

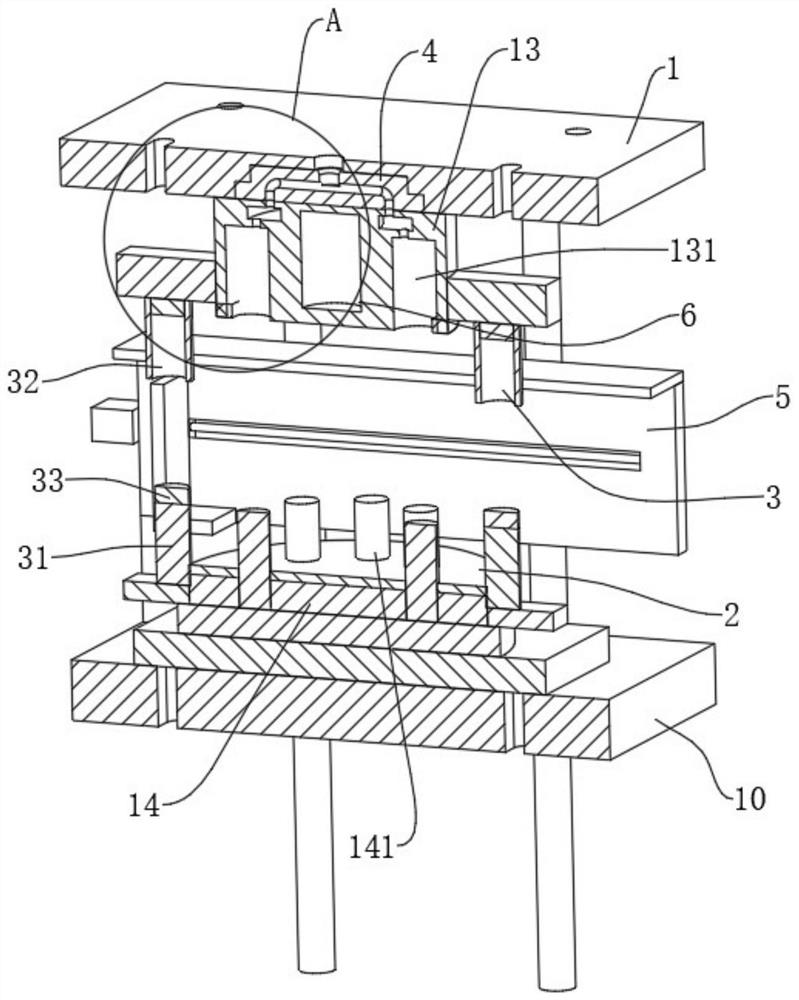

[0045] refer to figure 1 , figure 2 with image 3 One integrated port red tube is prepared, including the fixed-end of the fixed end in the injection molding machine and the movable die 10 mounted in the injection molding machine, where the fixed mold seat 1 is fixed to the side of the moving die 10 Several guides 11 in which the movable sleeve 12 is fixed to each other with the guide bar 11, which can provide the direction of the mold using the guide bar 11 and the guide sleeve 12; wherein the mold further includes the following portions: The fixed template 13 is mounted in the plane of the module 1, and a plurality of concave die cavities 131 for molding the red tube are fixed in the fixed template 13; mounted in the moving module 10 The template 14, and the movable die 141 is fixed to the dielectric core rod 141 for inserting the concave die cavity 131; a demolding assist of the exterior molding of the external molded core rod 141 is disposed on the moving template 14. Structure...

Embodiment 2

[0054] Unlike Example 1, the present embodiment also provides a preparation process of a molded plug-in manufacture, including the following steps:

[0055] S1, select T12 steel wire cutting and polishing manufacturing the exit molding 1 and the moving form 10, select the CR12MOV steel wire cutting and polishing the application of the model plate 13 and the moving template 14;

[0056] S2, the template 13 and the moving template 14 are larper, quenching and tempering heat treatment, after which the secondary grinding, wherein the isothermal ballification process is: heating in 860-890 ° C for 2 h, cooling to 740-760 ° C Isothermal 4h, the furnace is cold to 500 ° C, the quenching and tempering process are: heating temperature 1020-1050 ° C, oil cold or air cooling, control hardness 54-58 HRC, after 530-560 ° C for tempering.

[0057] S3, assemble the insert 41 to the fixed die 1;

[0058] S4, the template 13 is assembled to the fixed die 1, and the movable template 14 is assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com