Packing box multi-layer stacking mechanism

A packaging box and regularization technology, which is applied in the field of multi-layer stacking and regularizing mechanisms for packaging boxes, can solve the problems of poor reliability, high labor intensity, and low operating efficiency, and achieve the effects of reliable action, improved efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

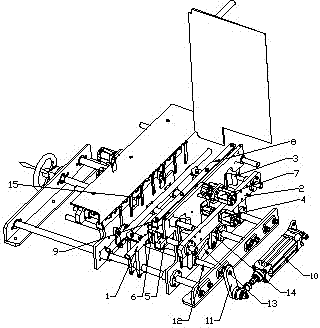

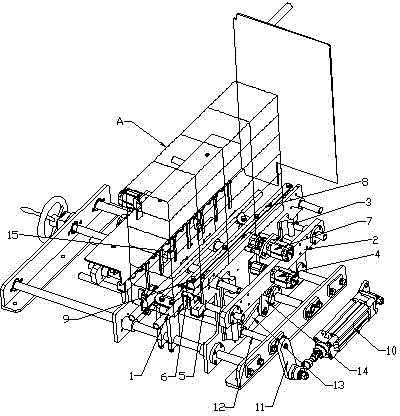

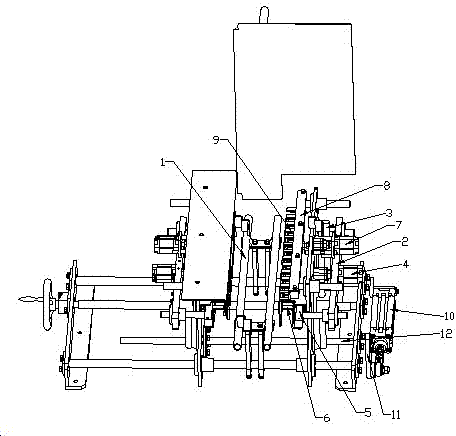

[0013] As shown in the figure, the packaging box multi-layer stacking regularization mechanism includes a conveying guide rail 1 for supporting the packaging box and capable of linearly conveying the packaging box along it; a lifting seat 2 is respectively arranged on both sides of the conveying guide rail 1, and the lifting seat Installed on the vertical guide rail 3 and can be raised and lowered along the vertical guide rail, a lower cylinder 4 is installed on the lifting seat 2 on each side, and the telescopic end of the lower cylinder is connected with a lower bracket 5 and can drive the lower bracket 5 to be opposite The conveying guide rail moves laterally and horizontally, and comb-shaped lower inserting plates 6 are arranged longitudinally on the lower bracket 5; a fixedly installed upper cylinder 7 is respectively arranged on both sides of the conveying guide rail 1, and each upper cylinder 7 The telescopic end is connected with an upper bracket 8 and can drive the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com