Instrument arm from operating end

An operating end and instrument arm technology, applied in the field of instrument arms, can solve the problems of increased elastic deformation and reduced repeat positioning accuracy of the end of surgical tools, and achieves the effects of compact structure, reduced robot volume, and improved rigidity and bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

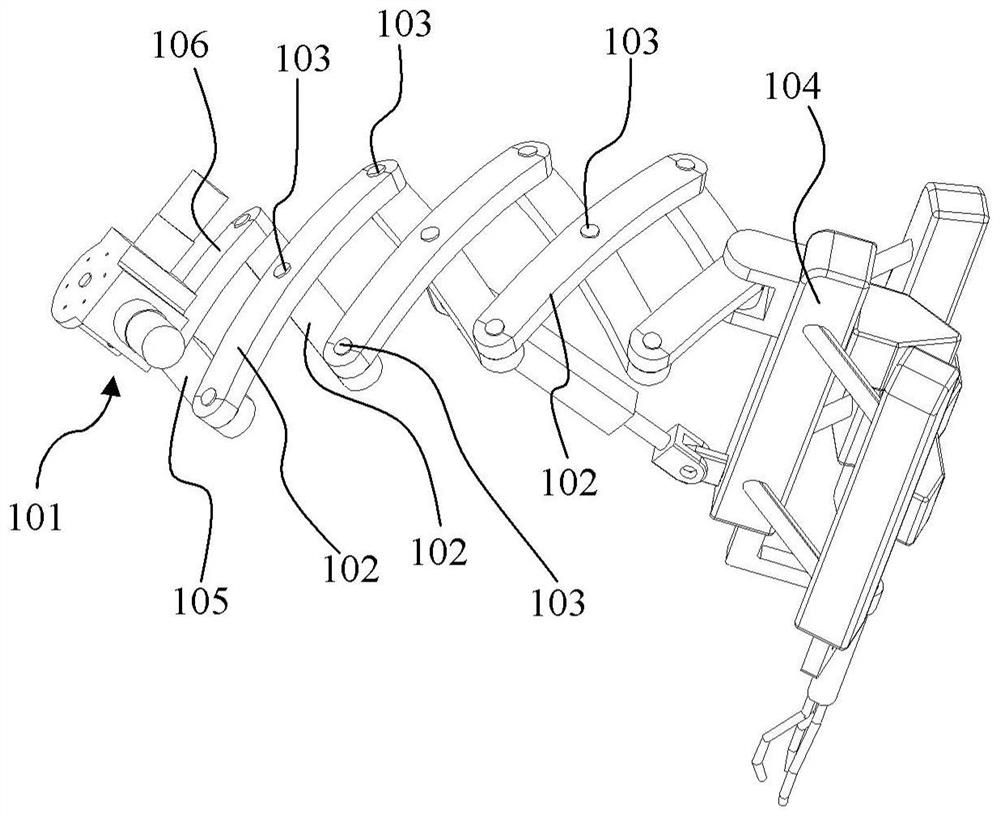

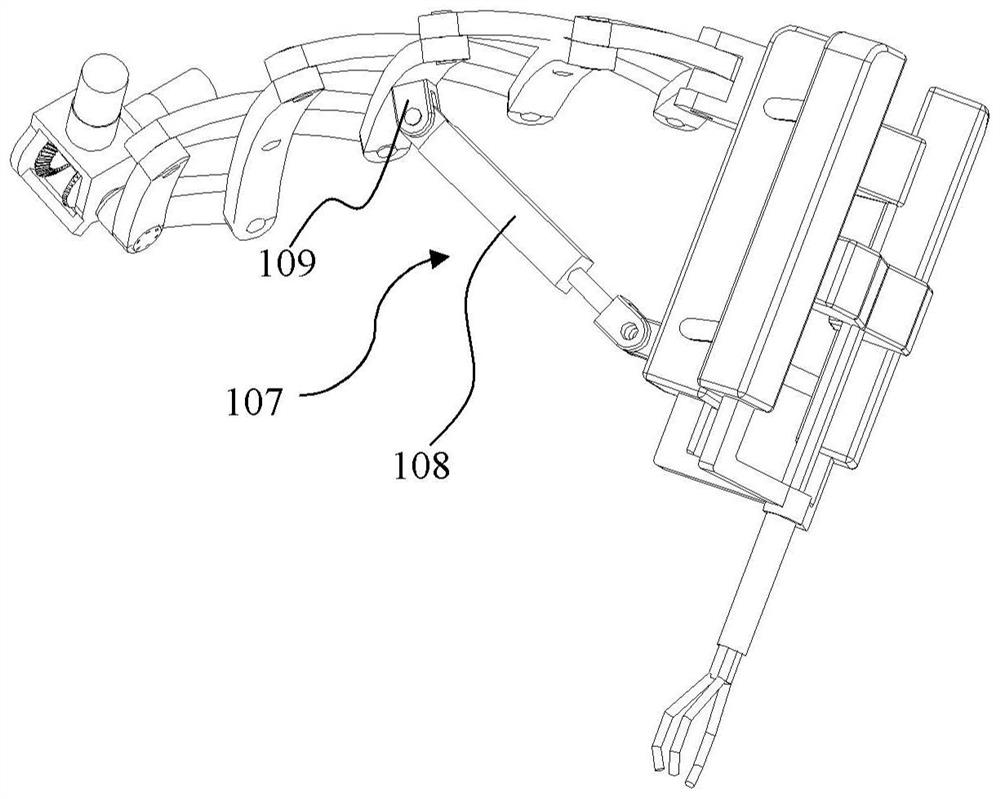

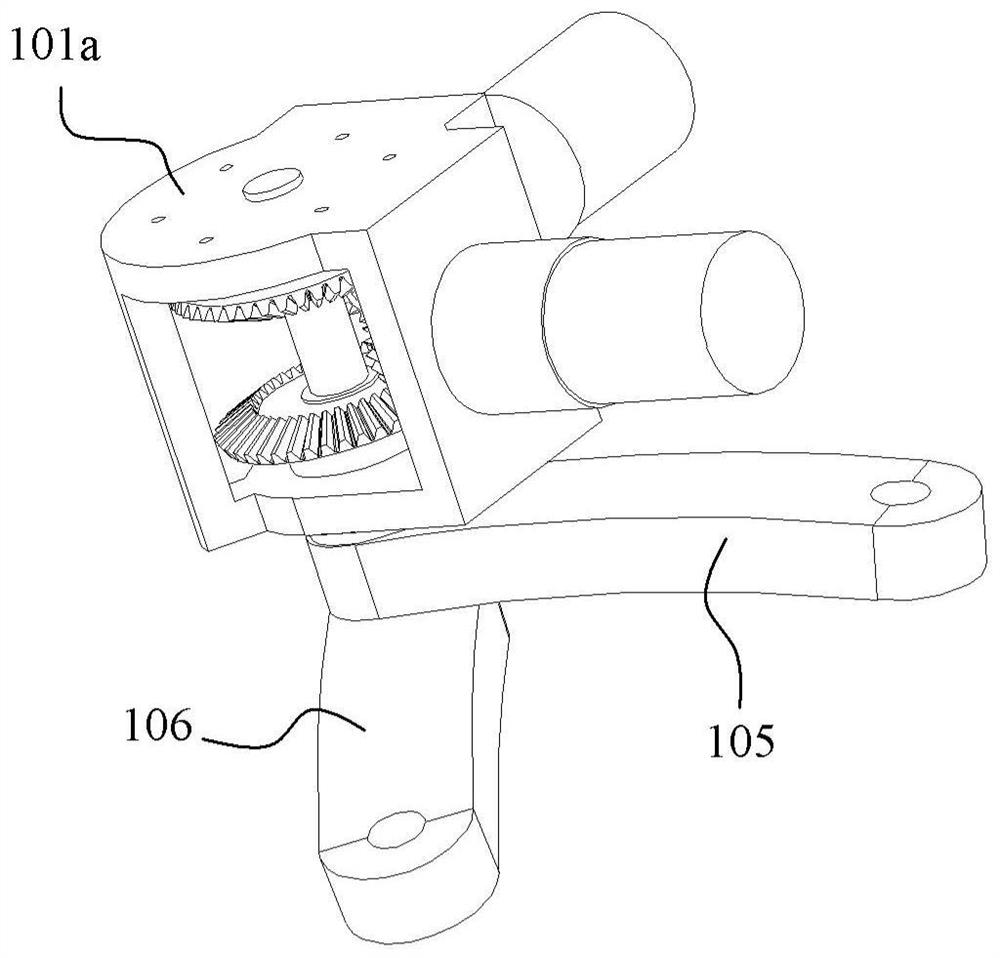

[0051] The disclosure provides an instrument arm from the operating end, which includes: a connection part, a control part, a distal execution part and an auxiliary arm. The connection part is a telescopic structure, including a driving end and a driven end; the two driving rods of the control part It is connected with the active end of the connection part, and the other end of the control part is connected with the slave operation end; one end of the remote execution part is connected with the driven end of the connection part, and the other end of the remote execution part is connected with the actuator; one end of the auxiliary arm is hinged with the lower part of the connection part, The other end of the auxiliary arm is hinged with the distal actuator; the control part controls the connecting part to expand and / or swing along a spherical surface, and makes the actuator always point to the center of the sphere corresponding to the spherical surface; the auxiliary arm expands...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com