A Self-cleaning Structure of Rotor Spinning Machine

A rotor spinning machine and self-cleaning technology, applied in spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve the problem of increased labor intensity of operators and dust accumulation in rotor condensing tanks. , low production efficiency and other problems, to reduce the labor intensity of workers, reduce the number of cleaning, and achieve the effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

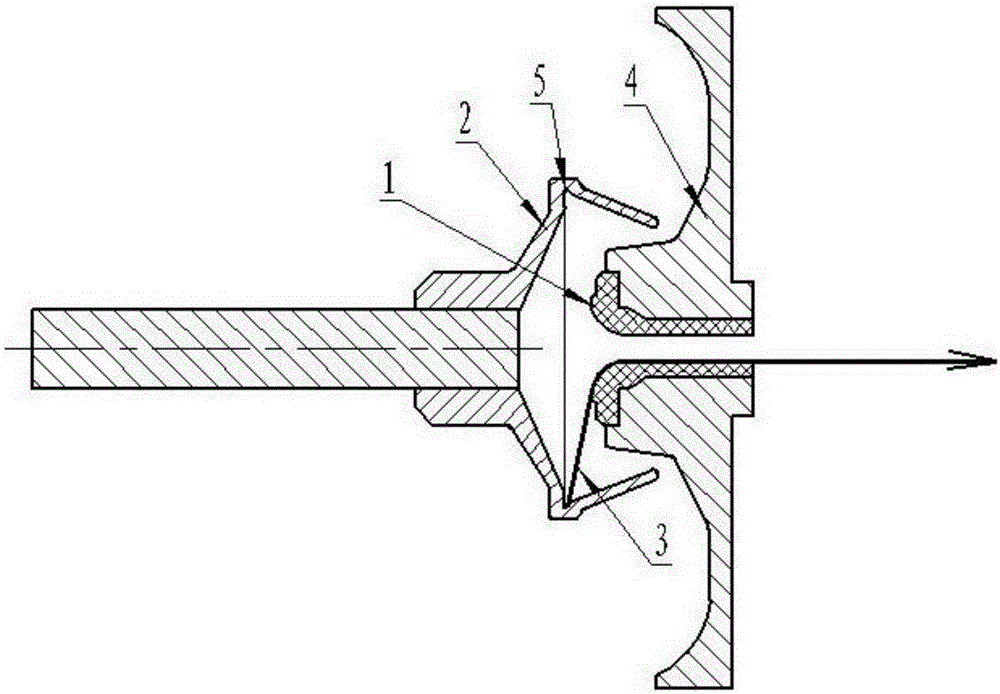

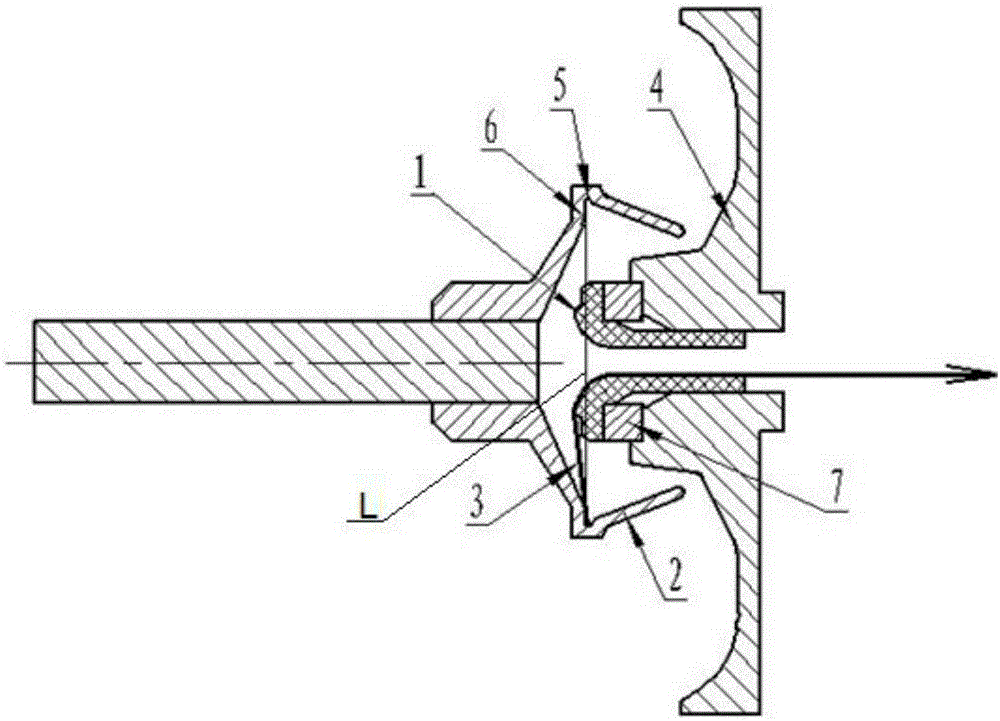

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

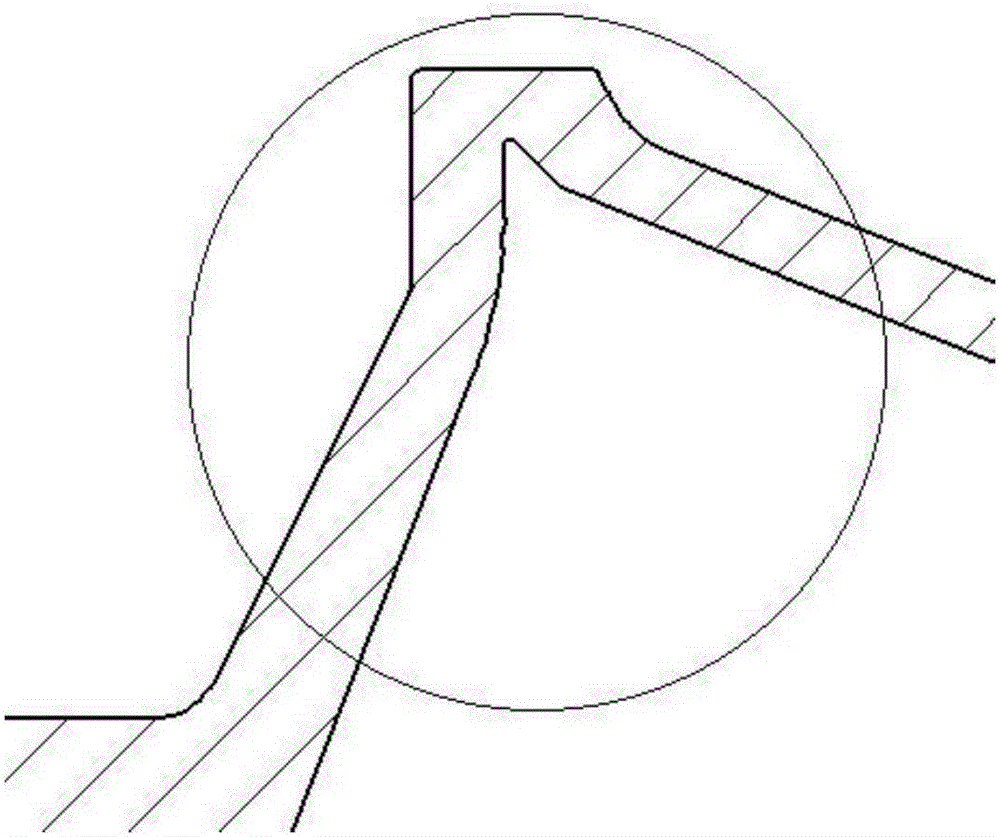

[0023] combine figure 2 As shown, a self-cleaning structure of a rotor spinning machine includes a T-shaped rotor 2 and an upper channel 4 for fiber delivery, and the T-shaped rotor has a condensation groove 5, such as image 3 As shown, the cross section of the condensation groove 5 is an acute angle, and a false twist disk 1 is installed on the upper channel of the fiber delivery, and the false twist disk stretches into the cup mouth of the rotor cup, and the top of the false twist disk (i.e. false twist disk 1) The leftmost side of the twist disc) is close to the bottom of the rotor and passes through the plane L where the bottom surface of the condensation groove 5 is located. The distance between the top of the false twist disk passing through the plane where the bottom surface of the condensation tank is located is 0.5 mm to 1 mm. Preferably, the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com