Acrylate adhesive, adhesive tape and preparation method thereof

A technology of acrylates and acrylates, which is applied in the direction of adhesives, ester copolymer adhesives, adhesive types, etc., and can solve problems such as easy peeling, low biochar content, and poor cohesion of tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

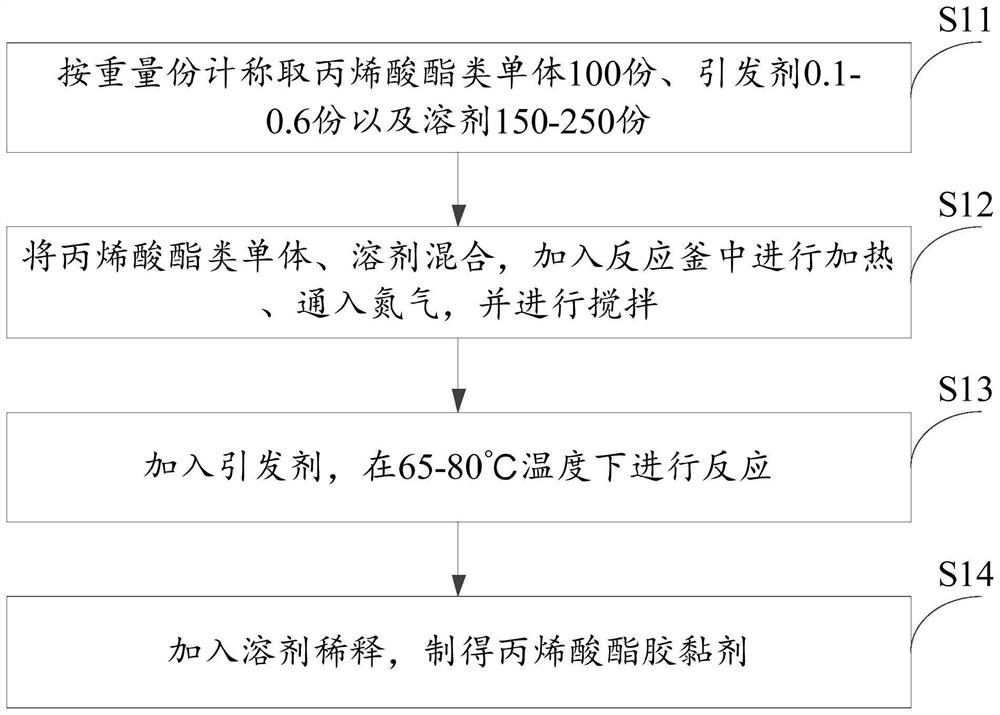

[0040] As the second aspect of this application, figure 1 The process flow diagram of the preparation method of a kind of acrylate adhesive provided for the application, as figure 1 As shown, the preparation method of the acrylate adhesive includes:

[0041] Step S11, weighing 100 parts of acrylate monomers, 0.1-0.6 parts of initiators and 150-250 parts of solvents by weight;

[0042] Acrylate monomer, initiator and solvent are weighed in parts by weight so that they meet the proportioning requirements for preparing the adhesive.

[0043] Step S12, mixing the acrylate monomer and solvent, adding it to the reaction kettle for heating, feeding nitrogen, and stirring;

[0044] Add acrylate soft monomer, acrylate hard monomer and acrylic functional monomer into the reaction kettle for heating, introduce nitrogen and stir to make acrylate soft monomer, acrylate hard monomer and acrylic functional monomer mix evenly . Among them, acrylate soft monomers are selected from butyl ac...

Embodiment 1

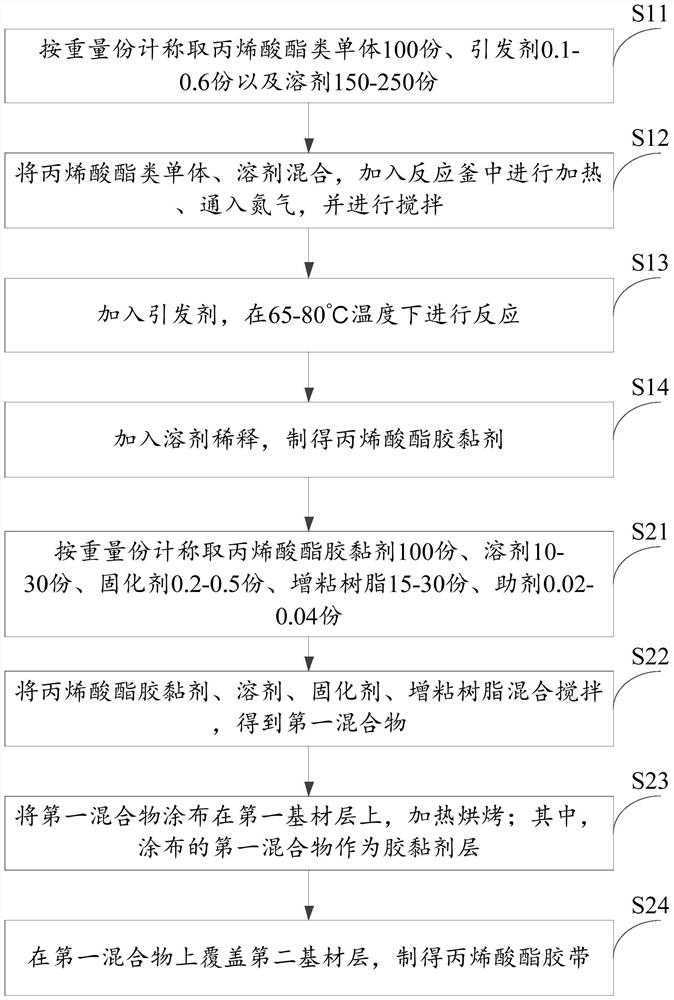

[0077] The preparation method of a kind of acrylate adhesive tape provided by this embodiment comprises the following steps:

[0078] (1) Preparation of acrylate adhesive:

[0079] Step S101, weighing 100 parts of acrylate monomers by weight, wherein, 60 parts of tridecyl acrylate, 45 parts of isobornyl acrylate, 5 parts of methyl acrylate, 4 parts of acrylic acid, and 1 part of hydroxyethyl acrylate; 0.1 part of azobisisobutyronitrile, 150 parts of toluene;

[0080] Step S102, put tridecyl acrylate, isobornyl acrylate, methyl acrylate, acrylic acid, hydroxyethyl acrylate, and 130 parts of toluene mixed into a 1000 ml reaction kettle, and smoothly introduce nitrogen for 1 hour (flow rate: 100 ml / min) , at the same time heated to 65 ℃ and evenly stirred for 60min, rotating speed 140R / min;

[0081] Step S103, add 0.05 part of azobisisobutyronitrile to react for 180 minutes, then heat up to 70°C, add 0.03 part of azobisisobutyronitrile to react for another 120 minutes, continue...

Embodiment 2

[0089] The preparation method of a kind of acrylate adhesive tape provided by this embodiment comprises the following steps:

[0090] (1) Preparation of acrylate adhesive:

[0091] Step S201, weighing 100 parts of acrylate monomers by weight, wherein, 40 parts of isooctyl methacrylate dodecyl acrylate, 50 parts of tridecyl acrylate, 3 parts of isobornyl acrylate, and 3 parts of isobornyl methacrylate. 2 parts of borneol, 7 parts of acrylic acid, 8 parts of hydroxyethyl acrylate; 0.3 parts of dimethyl azobisisobutyrate, 0.3 parts of tert-amyl peroxypivalate, 250 parts of ethyl acetate solvent;

[0092] Step S202, mix isooctyl methacrylate dodecyl acrylate, tridecyl acrylate, isobornyl acrylate, isobornyl methacrylate, acrylic acid, and hydroxyethyl acrylate, mix 130 parts of ethyl acetate solvent, and put into 1000 ml In the reaction kettle, nitrogen gas was introduced steadily for 1 hour (flow rate: 100ml / min), and at the same time, it was heated to 65°C and evenly stirred fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com