Optical fiber back-in reflection type lamp

A lighting and reflective technology, applied in the direction of lighting devices, lighting and heating equipment, parts of lighting devices, etc., can solve the problems of narrow lighting range, uncoordinated elegant environment, and monotonous light emitting surface of the light source, etc., to achieve The effect of expanding the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

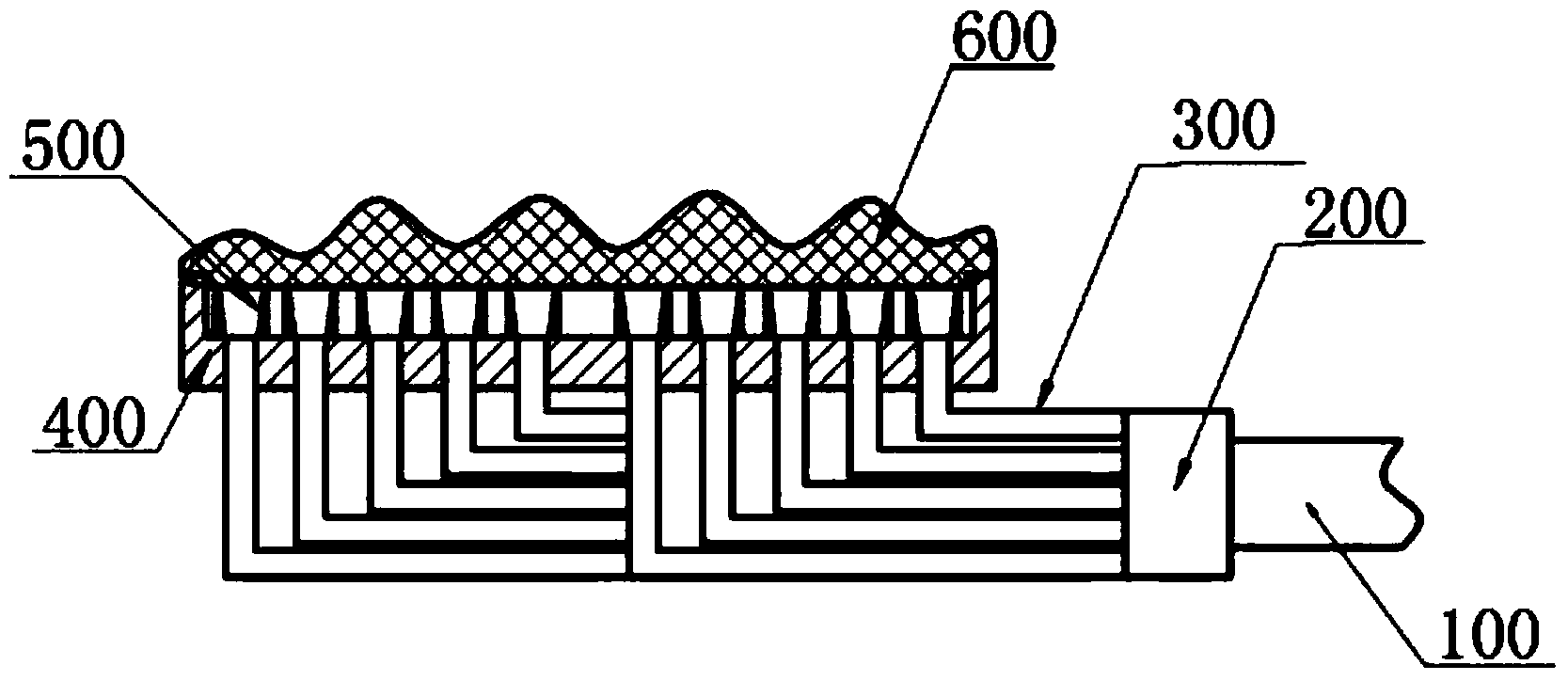

[0037] Figure 6 A structural schematic diagram of an optical system with reflective cups in the housing is shown. Such as Figure 6As shown in , the optical unit in the housing 400 is a reflective cup 510, the inner wall of the reflective cup 510 is coated with reflective material to form a reflective surface, and the whole is opaque, so as to avoid the loss of light entering the reflective cup due to transmission . Part of the sub-fiber 300 extends into the reflective cup 510, and the light output plate 600 is connected to the lower end of the reflective cup. The light output plate used in this embodiment is a light diffusion plate. When the lighting lamp is working, the light derived from the sub-fiber 300 enters the reflective cup 510, and is reflected by the inner wall of the reflective cup 510, so that the light beam can be diffused. The diffused light is further diffusely transmitted through the light-emitting plate 600 , making the emitted light soft.

Embodiment 2

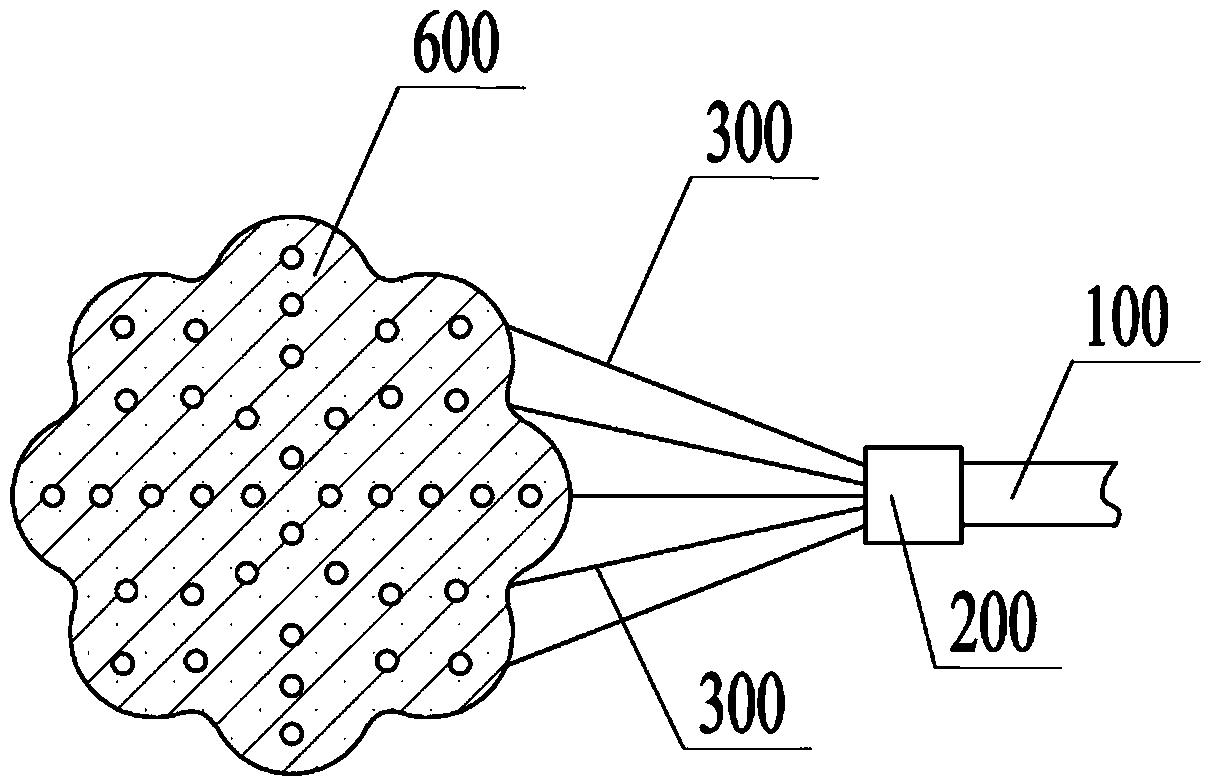

[0039] Figure 7 A schematic structural view of an optical system with reflectors in the casing is shown. Such as Figure 7 As shown in , the optical unit in the housing 400 is a convex mirror 520 . The convex mirror is a kind of spherical mirror, and the convex mirror has a diverging effect on the incident light. The light emitting plate used in this embodiment is a light diffusing plate. The light exported by the sub-fiber 300 is irradiated on the convex reflector 520, and the light is reflected by the reflector 520, so that the light beam can be diffused. The diffused light is further diffusely transmitted through the light-emitting plate 600 , making the emitted light soft. A light filter is pasted on the light output plate 600 , which can transmit light of different colors as required.

Embodiment 3

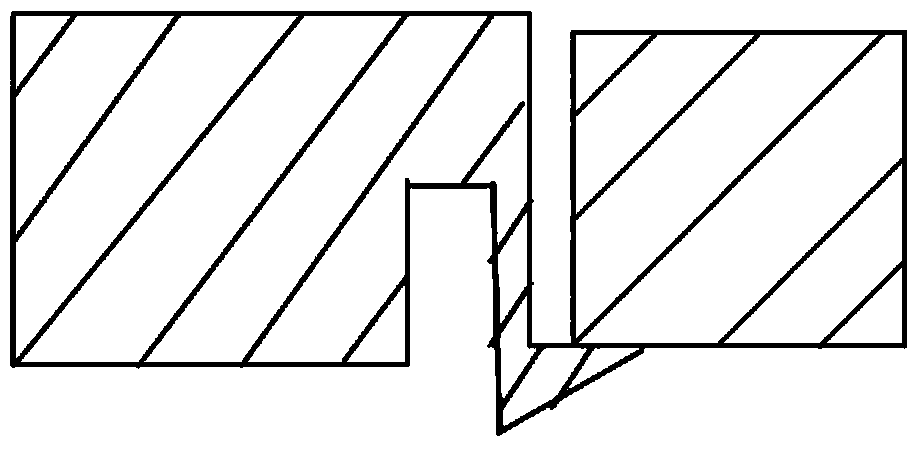

[0041] Figure 8 A schematic structural diagram of an optical system of a combination of a reflector and a reflector cup is shown, wherein the reflector is a convex reflector. Such as Figure 8 As shown in , a part of the light exported by the sub-fiber 300 enters the reflective cup 510, and the light is reflected by the inner wall of the reflective cup 510, so that the light beam can be diffused. Mirror 520, the reflected light is reflected by the convex mirror 520 located at the upper end of the casing, so that the light beam can be diffused. The diffused light is further diffusely transmitted through the light-emitting plate 600 , making the emitted light soft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com