Optical fiber back-entrance lens-type illuminating lamp

A technology for lighting lamps and optical lenses, which is applied in lighting devices, lighting and heating equipment, components of lighting devices, etc. The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

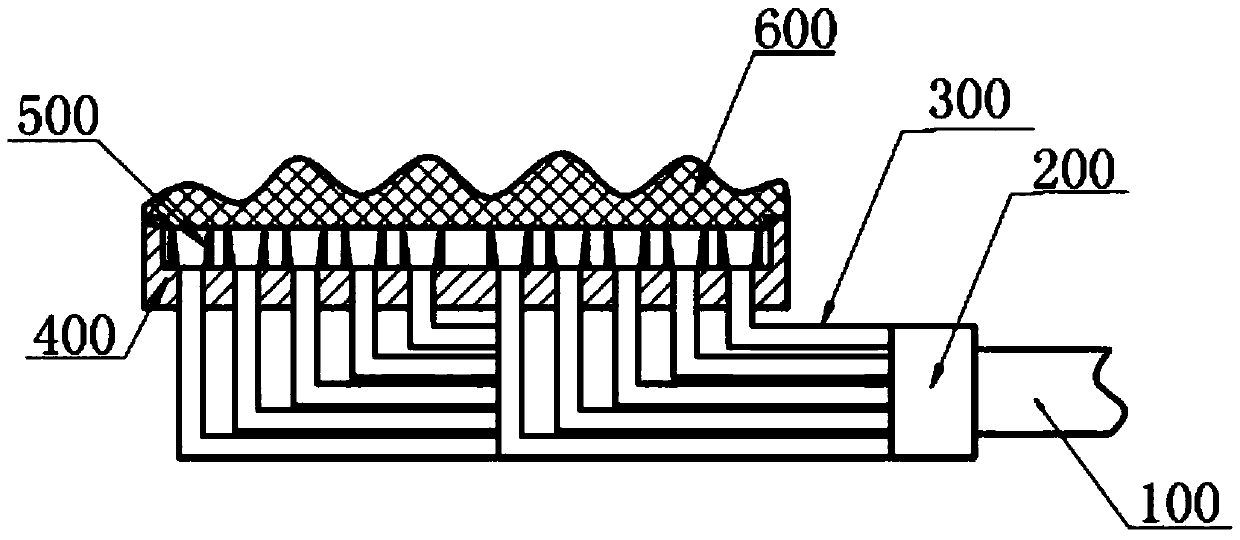

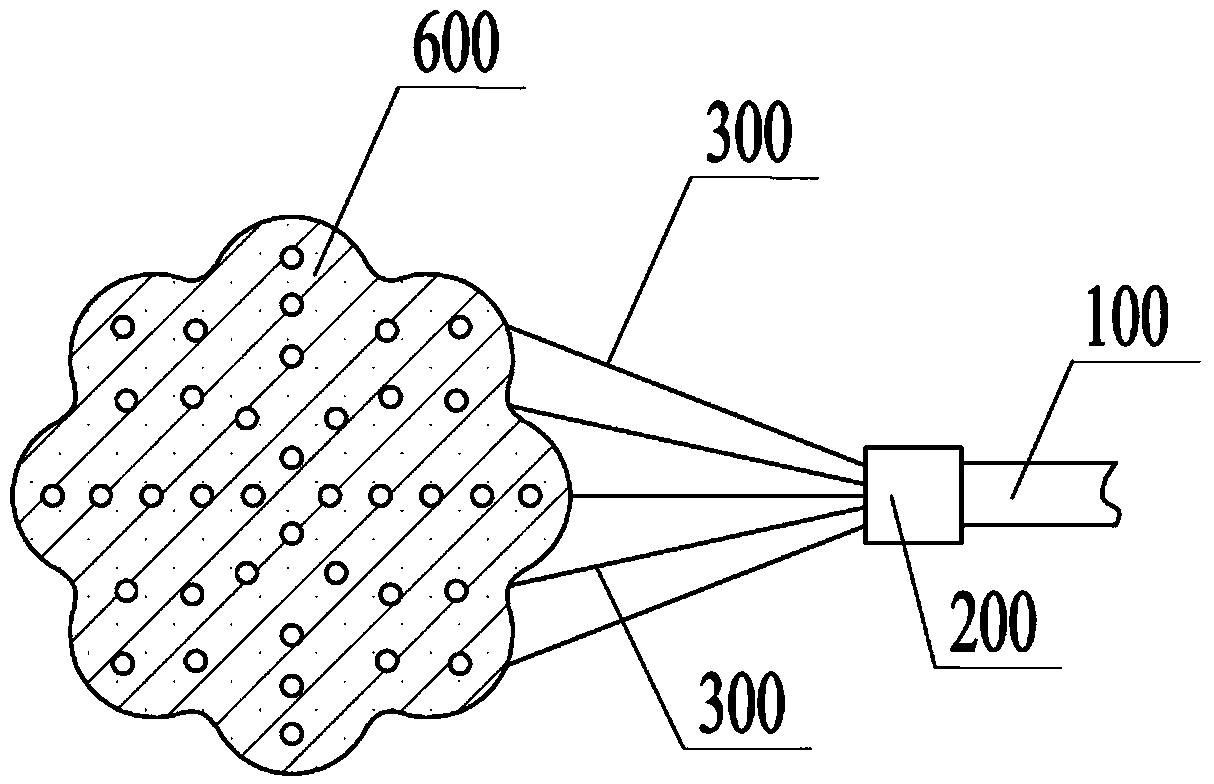

[0041] Image 6 A schematic structural diagram of the optical system is shown in which the optical lens in the housing is a concave lens. Such as Image 6 As shown in , the optical lens in the housing 400 is a concave lens 520, and the concave lens 520 is located between the sub-fiber 300 and the light-emitting plate 600. The parallel light exported by the sub-fiber 300 is diffused by the concave lens 520 and then passes through the light-emitting plate. 600 output, the light emitting plate used in this embodiment is a light diffusing plate. Figure 7 A schematic diagram of the optical path of the light guided by the sub-fiber passing through the concave lens is shown. Such as Figure 7 As shown, the parallel light derived from the sub-fiber 300 passes through the concave lens 520 in the housing 400 and diffuses along the virtual focus of the concave lens 520, so that the light beam can be diffused. The diffused light is further diffusely transmitted through the light-emit...

Embodiment 2

[0043] Figure 8 A schematic structural diagram of an optical system is shown in which the optical lens in the casing is a combination of a convex lens and a concave lens. Such as Figure 8 As shown in , a convex lens 510 and a concave lens 520 are installed in the housing 400, both of which are coaxial. In order to realize light diffusion, the convex lens 510 is arranged between the sub-fiber 300 and the concave lens 520, the concave lens 520 is arranged between the convex lens 510 and the light output plate 600, and the concave lens 520 is located between the convex lens 510 out of focus. Figure 9 A schematic diagram of the optical path of the light guided by the sub-fiber passing through the optical lens system is shown. Such as Figure 9 As shown, the parallel light derived from the sub-fiber converges at its focal point after passing through the convex lens 510, and becomes divergent light after passing through the focal point. The divergent light becomes more diverg...

Embodiment 3

[0045] Figure 10 It shows a schematic structural diagram of an optical system in which the optical lens in the casing is a combination of two concave lenses. Such as Figure 10 As shown in , two concave lenses 520 are installed in the housing 400 , the two are coaxial, and the two concave lenses 520 are both located between the sub-fiber 300 and the light output plate 600 . Figure 11 A schematic diagram of the optical path of the light guided by the sub-fiber passing through the optical lens system is shown. Such as Figure 11 As shown, the parallel light derived from the sub-fiber 300 diffuses along the virtual focus of the concave lens after passing through the first concave lens 520 , and the divergent light diffuses over a larger range after passing through the second concave lens 520 . The distance between the two concave lenses can also be adjusted. By moving one of the concave lenses or moving the two concave lenses at the same time to change the relative position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com