Horizontal-casting sectional demonstration experimental device and experimental method thereof

An experimental device and experimental method technology, applied in the field of teaching demonstration teaching aids, can solve the problems of low accuracy, inconspicuousness, and lack of true images of experimental results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

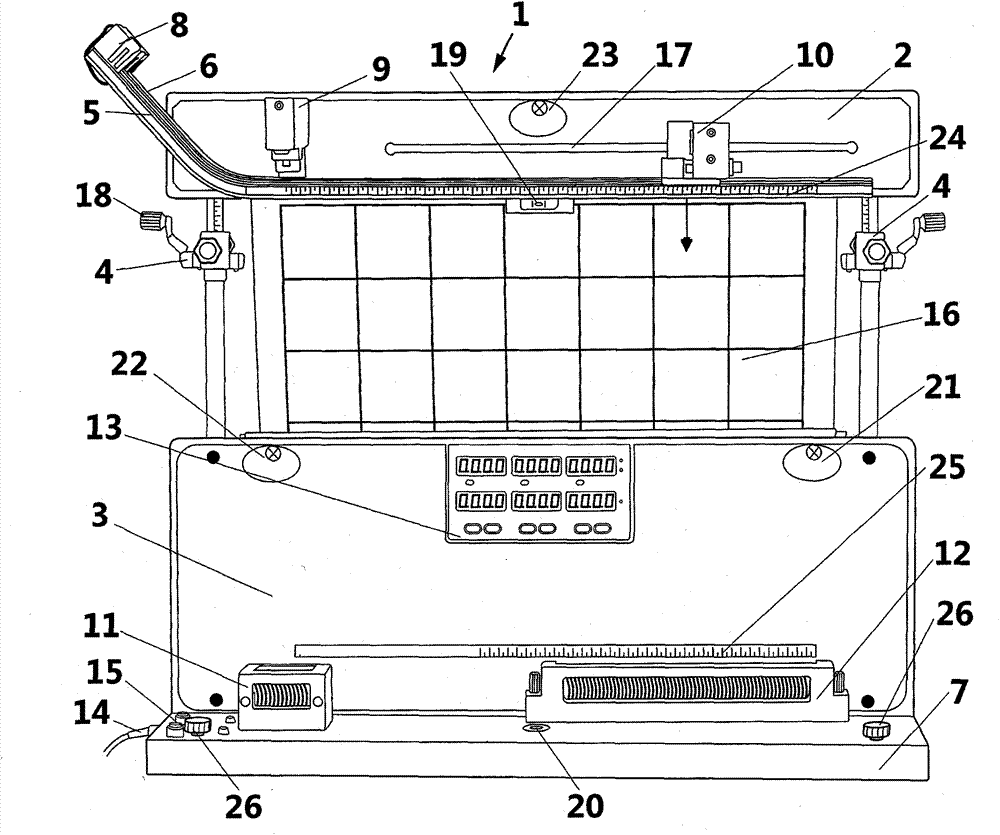

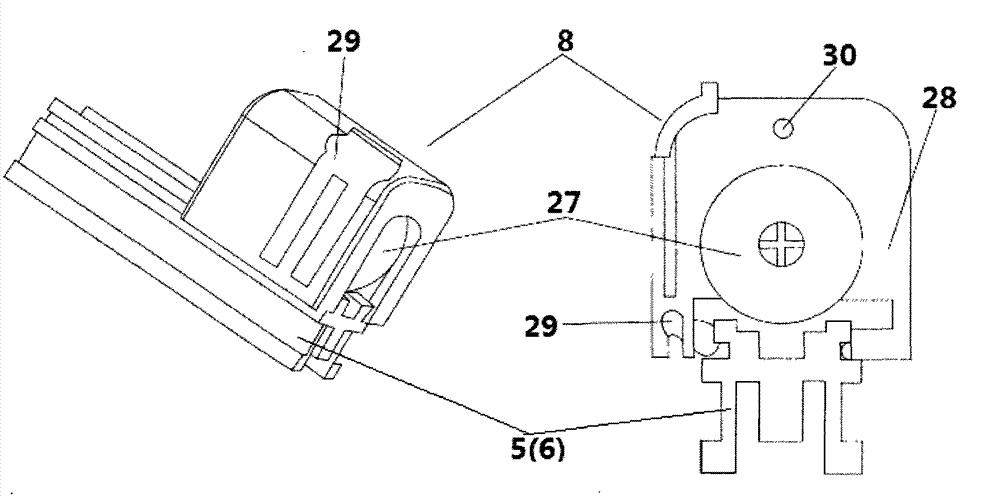

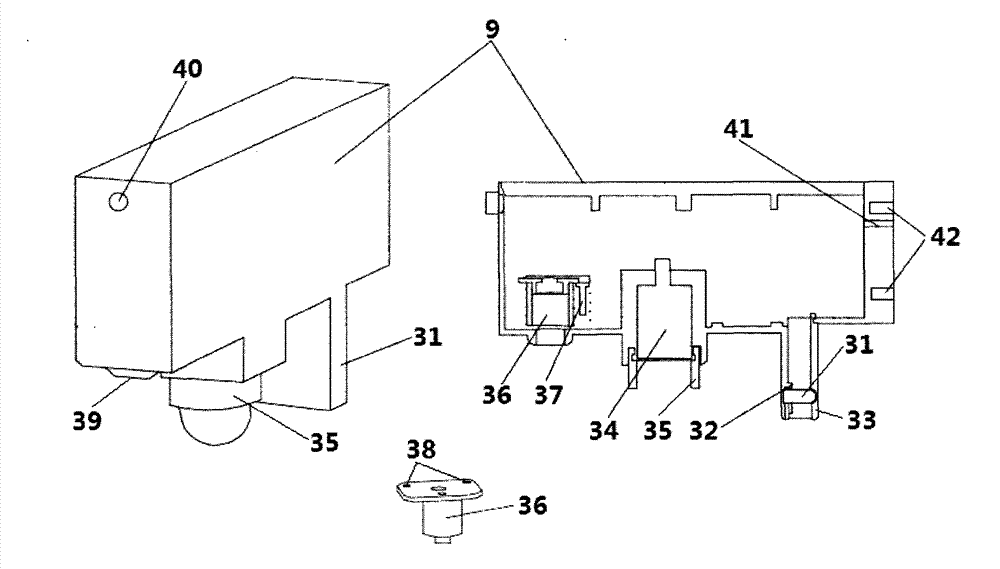

[0038] Such as figure 1 As shown, the present invention provides an embodiment of the horizontal polishing decomposition demonstration experiment device, including a demonstration experiment device main body 1 and a power input terminal 14. The demonstration experiment device main body 1 includes upper and lower risers 2, 3, which are connected to the upper and lower risers The telescopic rocker 4 is composed of an inner sleeve rod 78 with a scale that can move up and down, an outer sleeve rod 77 matched with the inner sleeve rod 78, and a lifting and rocking device 81 fixed to the port of the outer sleeve rod 77 The moving mode of the high and low telescopic rod 4 is a hand-cranked lifting and shaking device 81 to drive and control the up and down movement of the upper vertical plate 2. The lifting and shaking device 81 includes a rocker 18 for controlling lifting, a rotating screw 79, and a through The inner sleeve rod limit bolt 80 is used to limit the position of the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com