Test method for testing reliability of rocket high-temperature environment steel plate riveting process

A test method and high-temperature environment technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve the hidden dangers of use and operation, and cannot meet the reliability inspection of the steel plate willow joint process in the high-temperature environment of rockets Requirements, single inspection of mechanical structure or thermal performance and other issues, to achieve full reliability, reliable measurement results, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

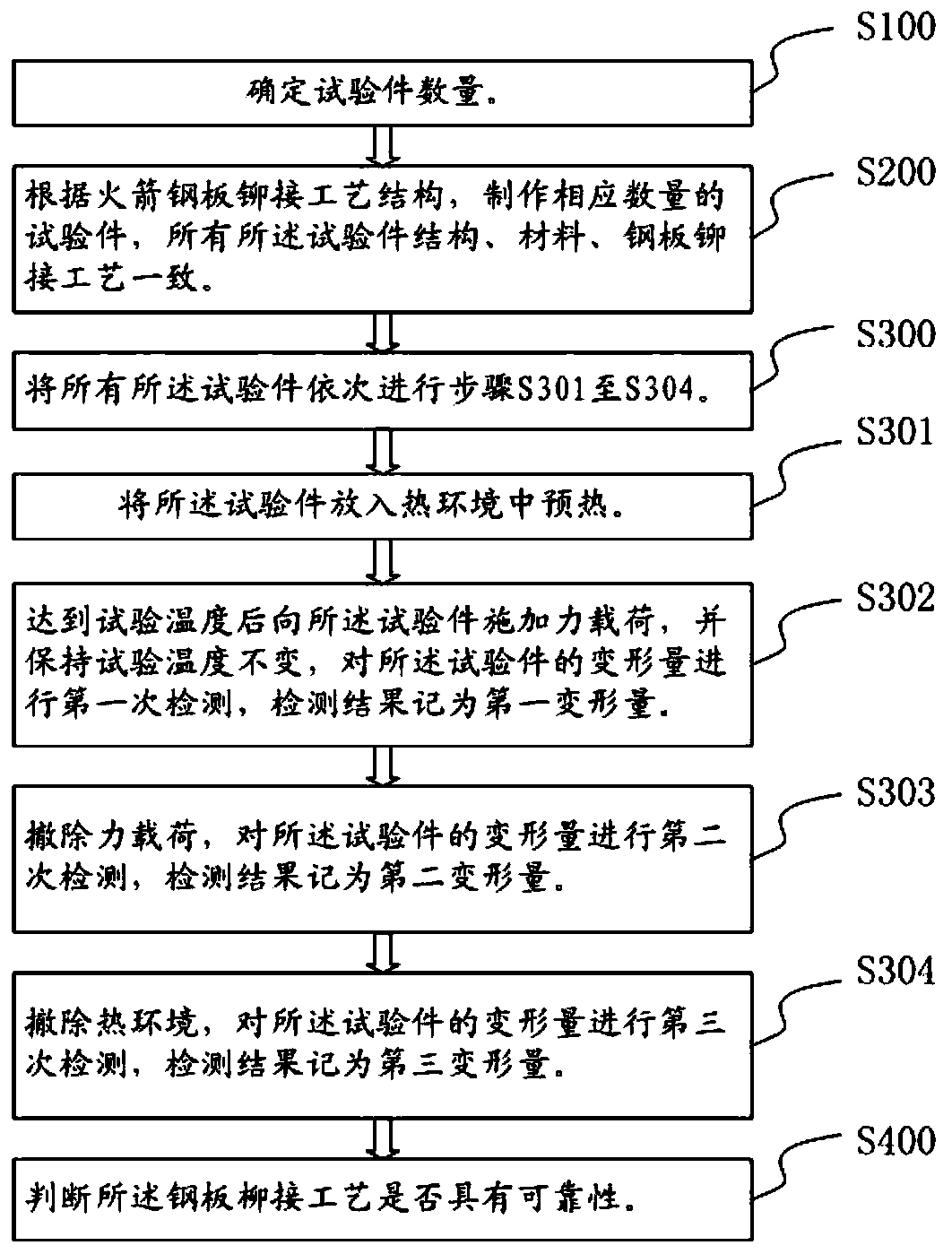

[0029] Please refer to figure 1 A flow chart of a test method for testing the reliability of the riveting process of steel plates in high-temperature environments for rockets provided by this application, including the following steps:

[0030] S100: determining the number of test pieces 1;

[0031] S200: According to the rocket steel plate riveting process structure, make a corresponding number of test pieces 1, and the structure, material, and steel plate riveting process of all the test pieces 1 are consistent;

[0032] S300: Perform steps S301 to S304 in sequence for all the test pieces 1;

[0033] S301: Put the test piece 1 into a hot environment to preheat, and the temperature of the hot environment is consistent with the temperature of the high-temperature environment of the rocket;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com