Assembling type casting-used target device

A target device and assembled technology, which is applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problems of heavy target plate and target frame, non-reusable, waste of resources, etc., to save manpower, The effect of flexible use and saving material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

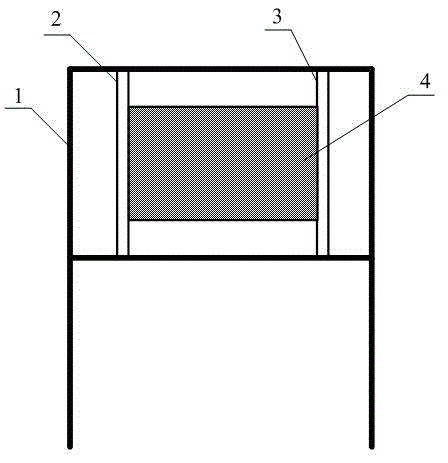

[0010] When in use, first fix the two ends of the target plate 4 on the slider one 2 and the slider two 3 respectively, and then fix the two ends of the slider one 2 and the slider two 3 on the target frame 1 with clamps , to carry out the projectile experiment, if the target plate 4 is damaged during the experiment, disassemble the target plate 4 from the slider 1 2 and the slider 2 3, and replace it with a new target plate, the experiment can be continued. 2 or slide bar 2 or 3 are damaged, just replace the slide bar to continue the experiment. In this way, only the damaged part of the target device needs to be replaced during the projectile experiment, which saves manpower and material resources and improves the flexibility of the experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com