Nondestructive testing method for blast furnace lining

A non-destructive testing and blast furnace technology, applied in the field of metallurgy, to achieve the effect of improving detection accuracy, avoiding errors, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for non-destructive testing of blast furnace linings, comprising the following steps:

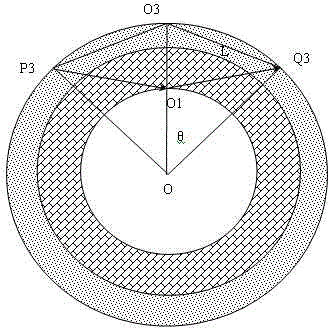

[0042] Such as figure 1 As shown, step 1: determine a measured point O1 on the inner wall of the blast furnace;

[0043] Step 2: use the first acceleration sensor as a trigger sensor, and use the second acceleration sensor as a receiving sensor;

[0044] Step 3: Place the first acceleration sensor and the second acceleration sensor on the vertical projection point O3 of the measured point on the outer wall of the blast furnace, set an excitation source next to the first acceleration sensor, and the excitation source hits the outer surface of the blast furnace to generate elastic waves , record the trigger time when the first acceleration sensor detects the elastic wave, record the receiving time when the second acceleration sensor detects the elastic wave, subtract the triggering time from the receiving time to get the elastic wave propagation time .

[0045] Step 4: Tak...

Embodiment 2

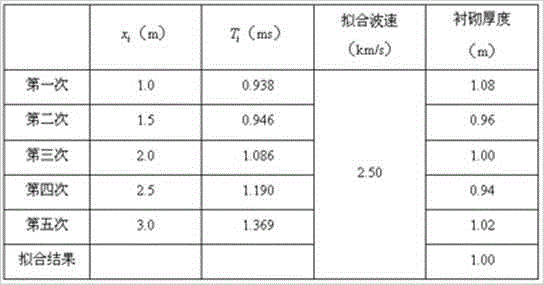

[0066] Repeat step 4~step 5 three times to get multiple groups and , and then fit it to get the optimal and .

[0067] As shown in Table 1:

[0068] Table 1

[0069]

[0070] Compared with the actual furnace wall thickness (1.01m), the test error of this embodiment is about -1%. It can be seen that the test accuracy has been greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com