vacuum cleaner mouth

A technology for vacuum cleaners and suction ports, which is applied in the direction of vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve the problems that the inclination position of the vacuum cleaner nozzle cannot be effectively compensated, and achieve the effect of saving space, large vertical stroke, and realizing vertical stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

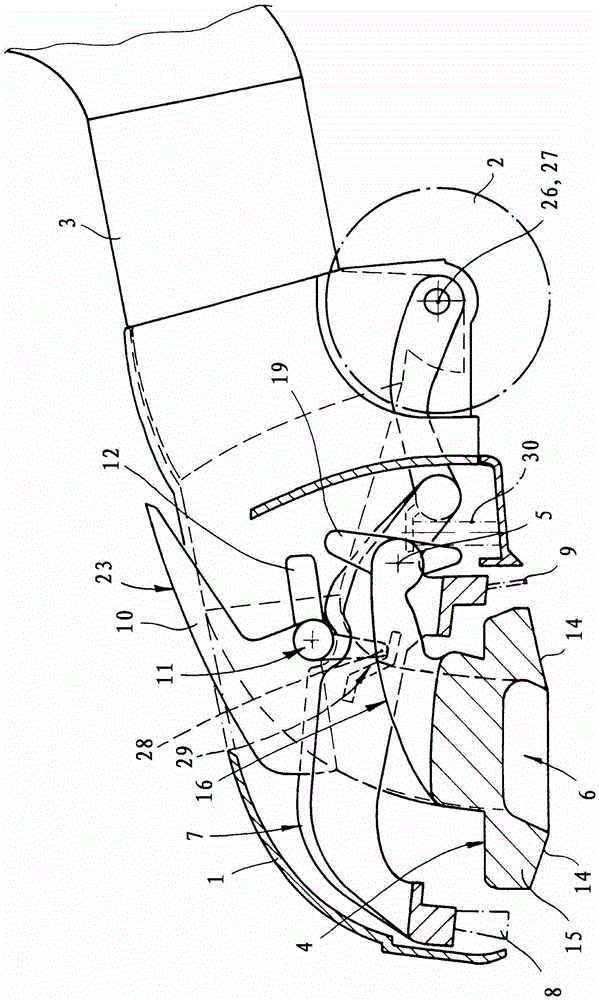

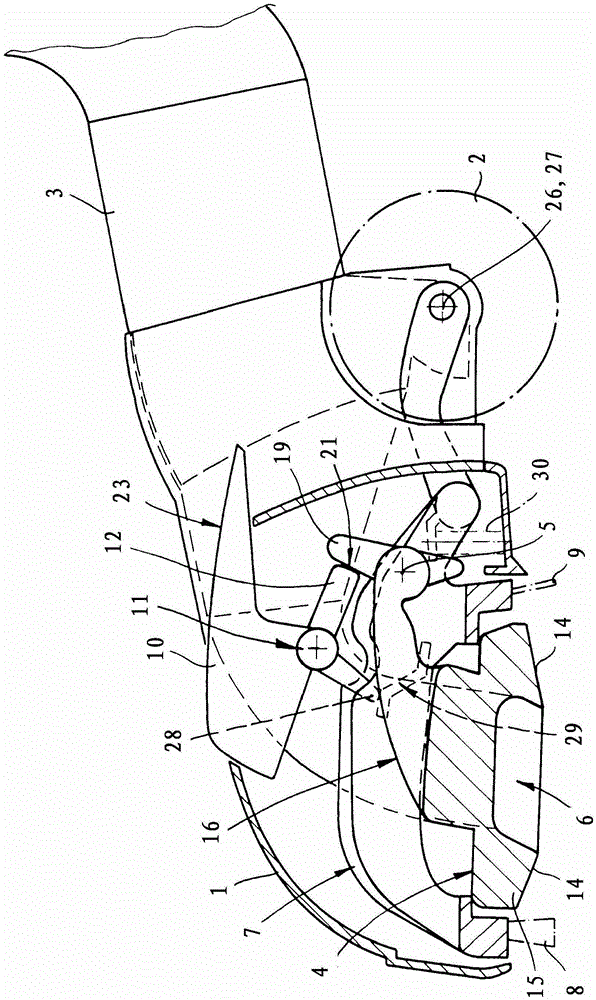

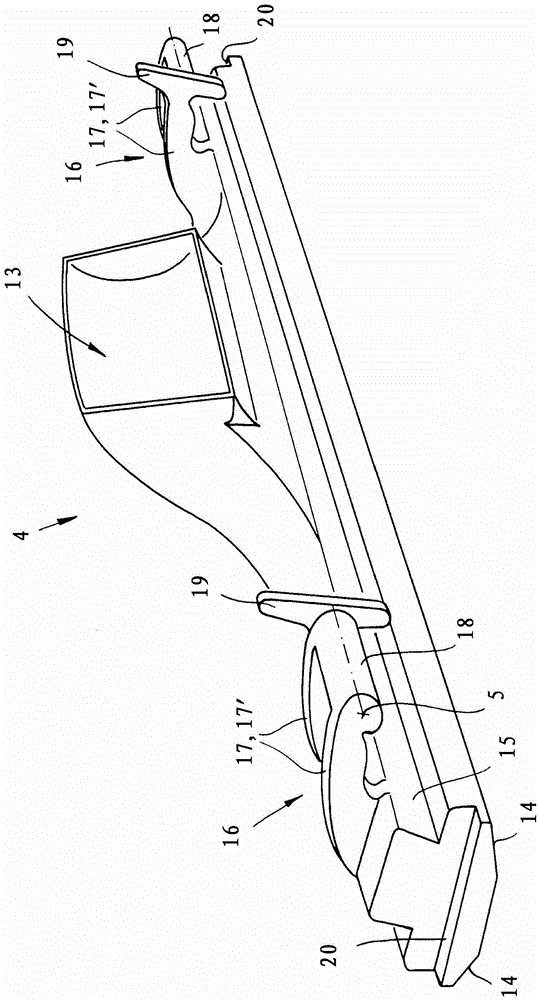

[0016] exist figure 1 with figure 2 The basic structure of the vacuum cleaner nozzle shown in includes a housing 1 supported on the rear side on at least one roller 2, a vertically deflectable connecting plate 3 for connecting the suction pipe and a floor slide 4, which slides The part is supported tiltably in the housing 1 about a pivot axis 5 and has a suction opening 6 . Furthermore, a carrier 7 is provided, on the underside of which at least one brush strip 8 and / or at least one sealing lip 9 are arranged. The carrier 7 is pivotally mounted in the housing 1 and is connected to a switch element 10 in a figure 1 shows the location of the carpet floor and a figure 2 Adjustable between smooth floor positions shown.

[0017] In the carpeted floor position, the frame 7 is raised and neither the brush strip 8 arranged on the underside of the frame 7 nor the sealing lip 9 likewise arranged on the bottom side of the frame 7 touch the floor. The vacuum cleaner nozzle is suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com