nailer

A technology for nail drivers and pins, which is applied in the field of nail drivers, and can solve the problems of falling off, reducing the fixing strength, and skewed placement of nails, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

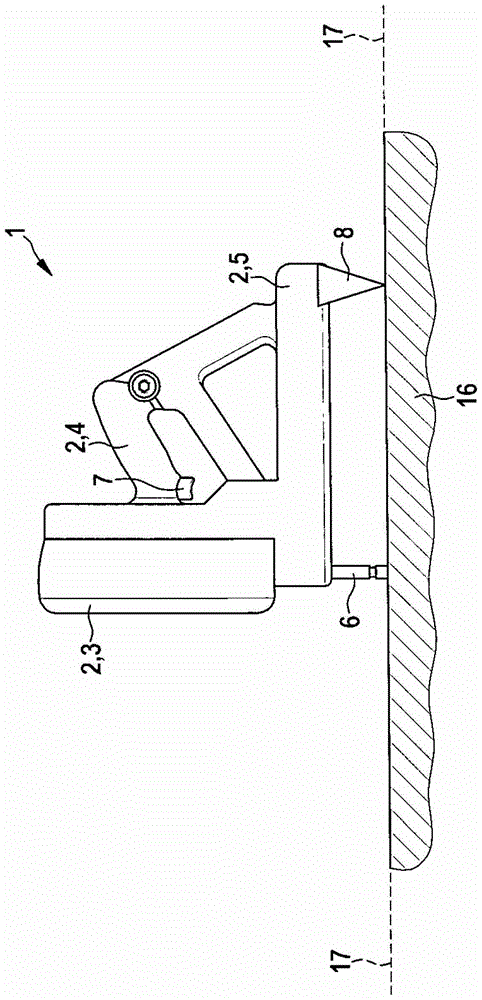

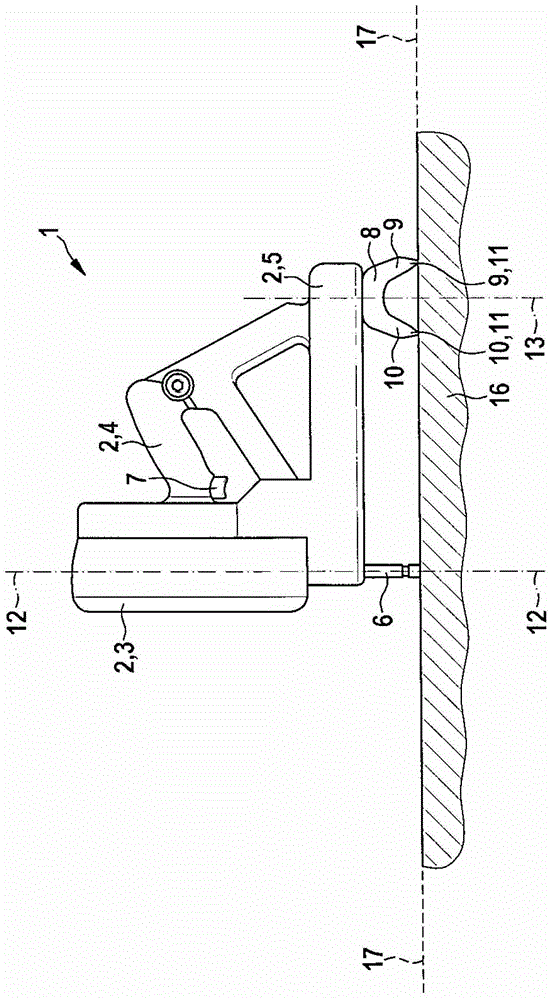

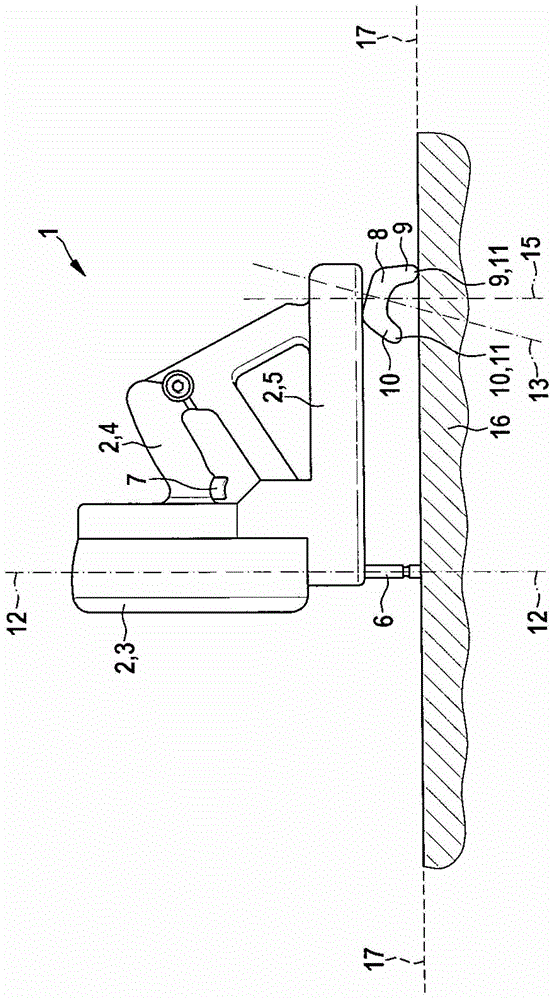

[0036] The nail driver 1 is used to drive a nail (not shown) into an object 16 or a substrate 16 made of wood, concrete or steel, for example. For this purpose, the nail driver 1 has a housing 2 made of metal and / or plastic, which is generally multi-part. Inside the nail driver body 3 surrounded by the housing 2 there is a mounting mechanism (not shown in the figure), which is operated electrically, pneumatically or in combustion technology. Surrounded by another part of the housing 2 is a magazine 5 . The nail magazine 5 contains a large number of nails. In order to place the nails, the nails must be transported from the nail magazine 5 to the placement mechanism, and the nails are driven electrically or pneumatically by the placement mechanism through a pin guide element 6 as an integral part of the placement mechanism. Drive into object 16 . The pin guide element 6 here has a longitudinal axis 12 , the positioning mechanism can be activated by means of a trigger 7 . In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com