Middle supporting structure of automobile transmission shaft

A technology of intermediate support and transmission shaft, which is applied to vehicle parts, control devices, transportation and packaging, etc., to achieve the effect of reasonable design, easy molding and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

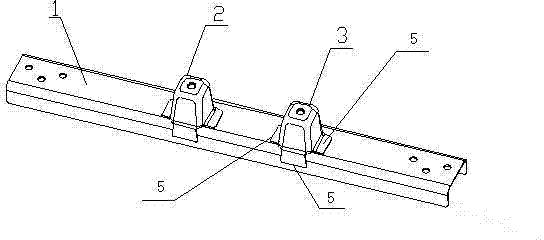

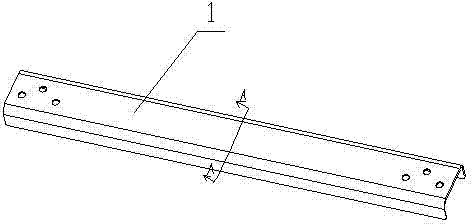

[0015] see Figure 1-4 The shown intermediate support structure for the transmission shaft of an automobile includes a long support body 1, which is characterized in that: a left support bracket 2 is provided on the left part of the support body, and a right support bracket is provided on the right part The bracket 3, the left support bracket 2 and the right support bracket 3 have the same structure; a projection welding nut 4 is positioned and connected to the upper ends of the left support bracket and the right support bracket.

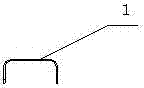

[0016] Furthermore, the cross-section of the support body is in an inverted "U" shape. Compared with the previous double-layer part cavity structure, it has the characteristics of simple structure, light weight, low cost and easy molding.

[0017] Further, the left support bracket and the right support bracket are box-shaped structures.

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com