A multi-stage self-priming centrifugal pump impeller guide vane structure

A self-priming centrifugal pump and impeller technology, applied in the field of centrifugal pumps, can solve the problems of impeller diameter size limitation and high production cost, and achieve the effects of reducing production cost, reducing leakage loss and improving single-stage lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

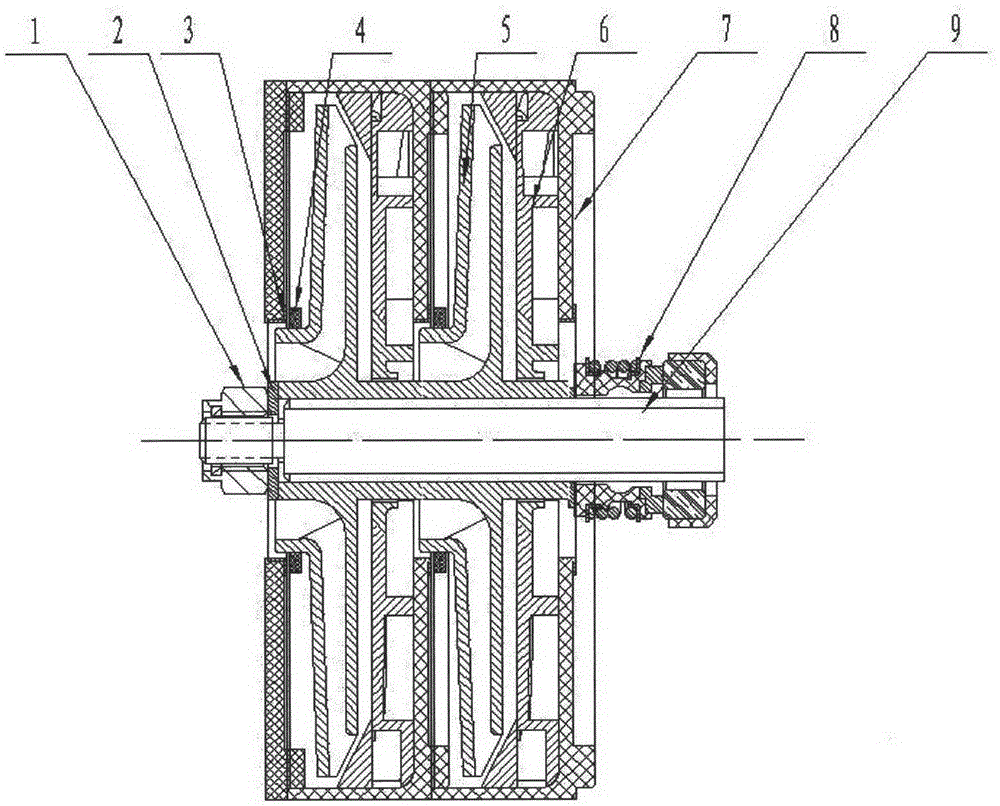

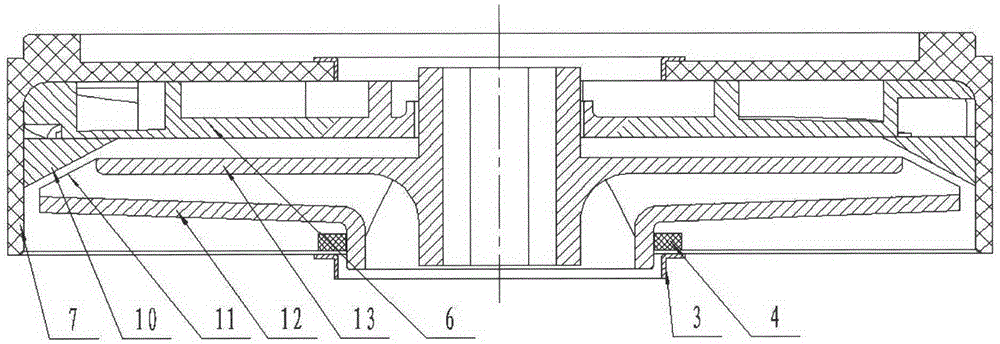

[0012] exist figure 1 Among them, the impellers (5) of each stage are set on the shaft (9), the hexagonal lock nut (1) and the washer (2) are placed at the inlet of the first stage impeller (5), and the mechanical seal (8) is placed at the last stage At the outlet of the impeller (5), the impellers (5) of all stages are axially fixed and rotate with the shaft (11). The stainless steel insert (3) is inlaid at the outlet of the guide vane cover (7), the impeller inlet retaining ring (4) is made of PPO (polyphenylene ether) material and placed at the inlet of the impeller (5), and the impeller inlet The retaining ring (4) can be moved, and the stainless steel insert (3) composed of two different materials forms a set of sealing device with the impeller inlet retaining ring (4). The pressure difference generated when the impeller (5) rotates forces the impeller inlet retaining The ring (4) fits tightly against the stainless steel insert (3), thus reducing the amount of leakage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com