Efficient high-lift universal well pump

A high-lift, general-purpose technology, applied to parts, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of low single-stage lift, unreasonable structure, high efficiency and narrow, etc., and achieve single-stage Increased lift, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

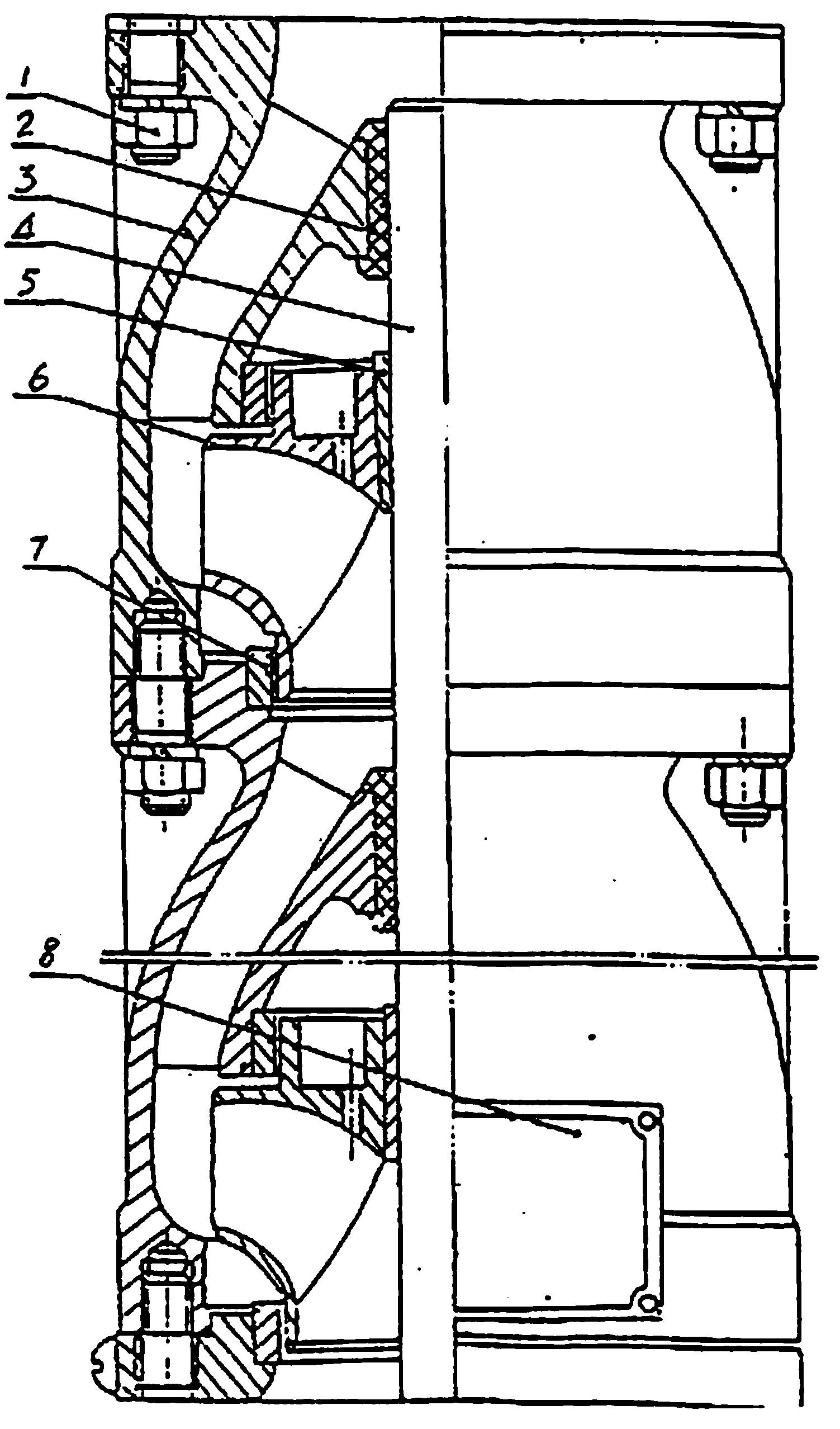

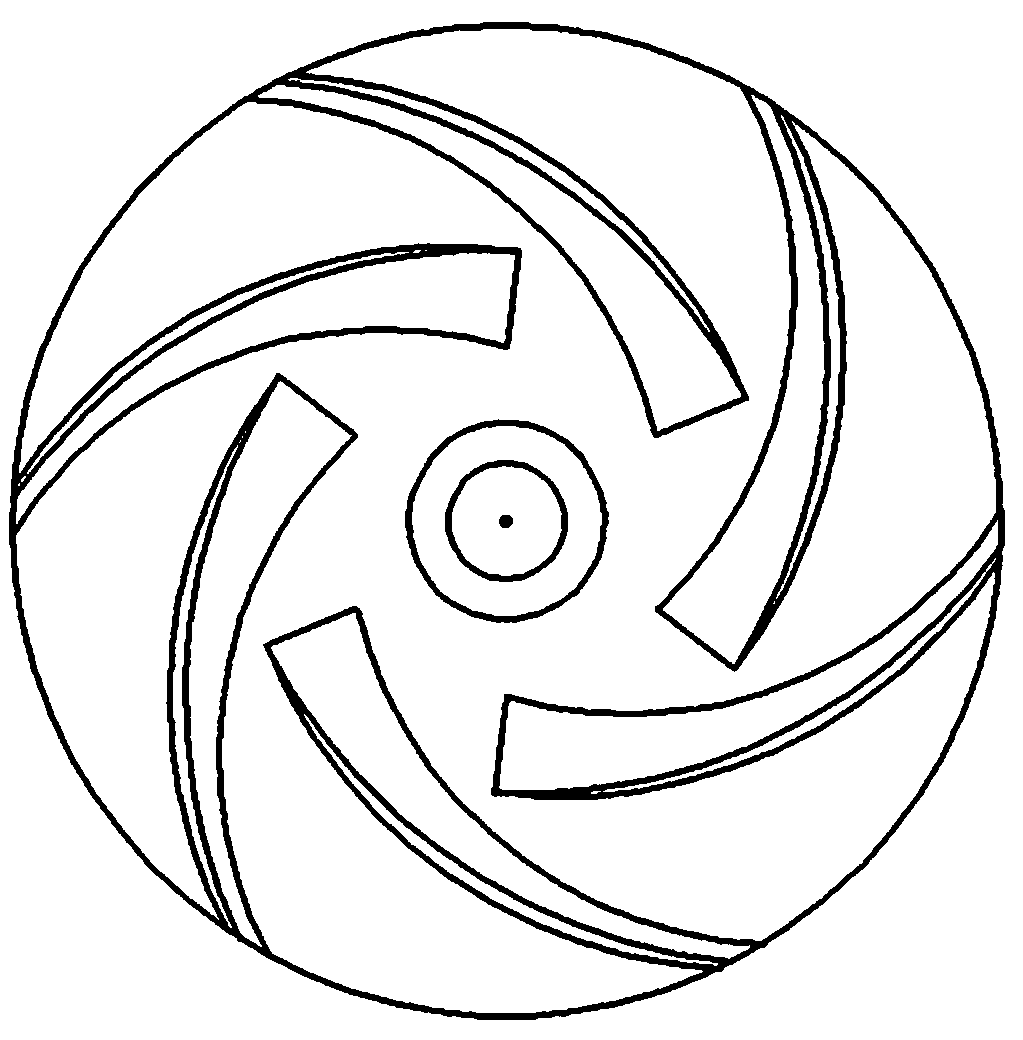

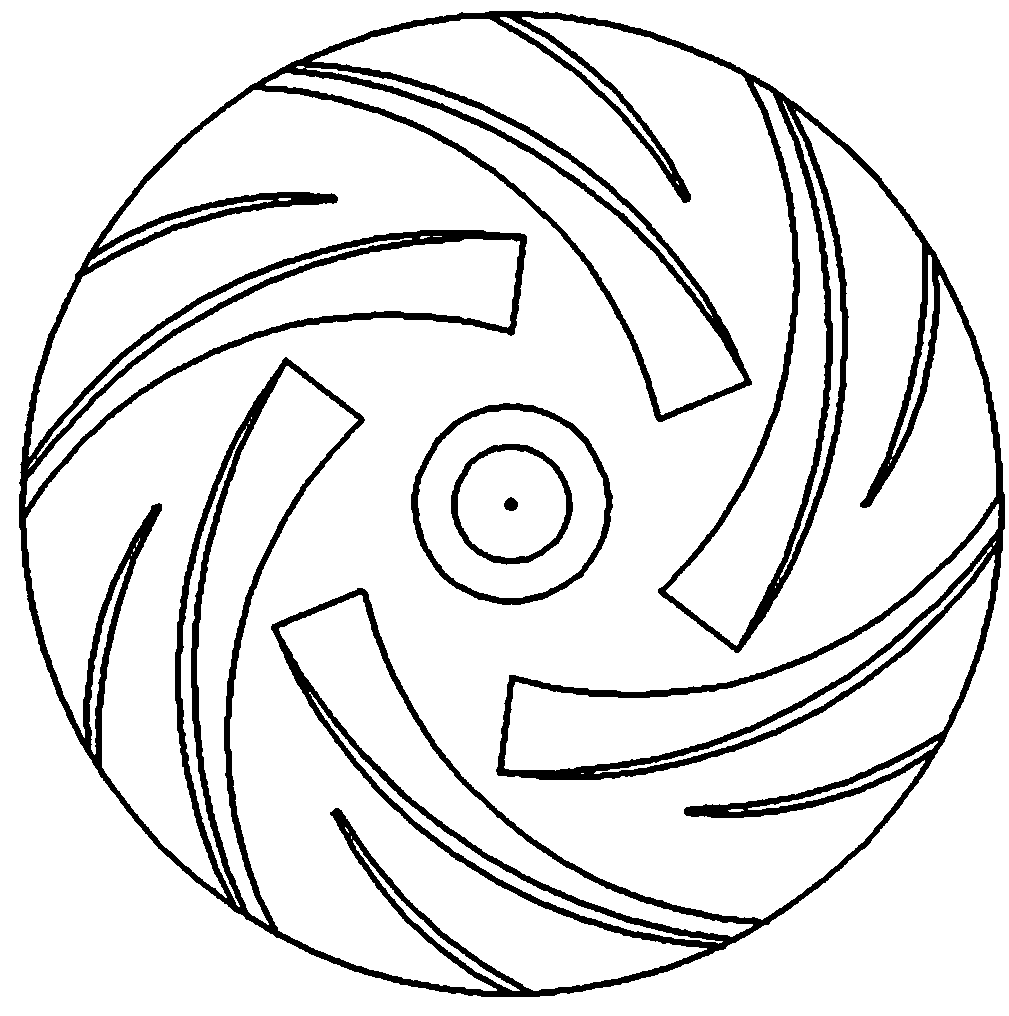

[0029] see figure 1 , image 3 , Figure 4 , Figure 5 , Figure 7 , the high-efficiency high-lift general-purpose well pump includes a guide casing 3, a pump shaft 4, and an impeller 6. The impeller 6 includes long blades, a rear cover plate and a front cover plate with a water inlet in the middle. It is characterized in that the impeller 6 also has Short blades are provided, and the short blades are located in the outer edge area of the impeller 6, and between two adjacent long blades; the length ratio of the short blades to the long blades is 0.40--0.80:1; the long There are at least 3 leaves, and the ratio of long leaves to short leaves is 1:1, or 1:2 or more; or the long leaves are twisted leaves, and the short leaves are arc-shaped leaves. Or the long blades are arc-shaped blades, and the short blades are twisted blades. The long blades are twisted blades, and the short blades are twisted blades. A rubber bearing 2 is provided between the pump shaft 4 and the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com