Multi-spindle machining center and system with micro-motion compensation function

A processing center and spindle processing technology, which is applied in the direction of manufacturing tools, comprehensive factory control, and other manufacturing equipment/tools, etc., can solve problems such as difficulty in fine movement, and achieve the effect of small movement range, convenient operation, and reduced operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

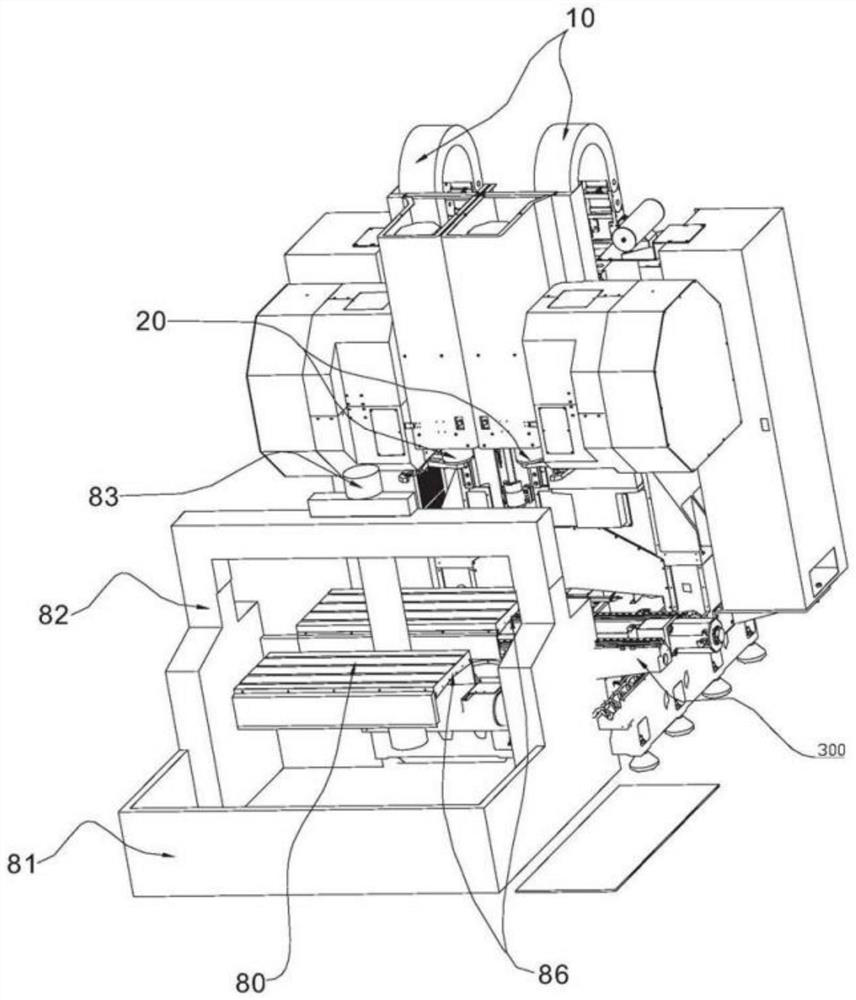

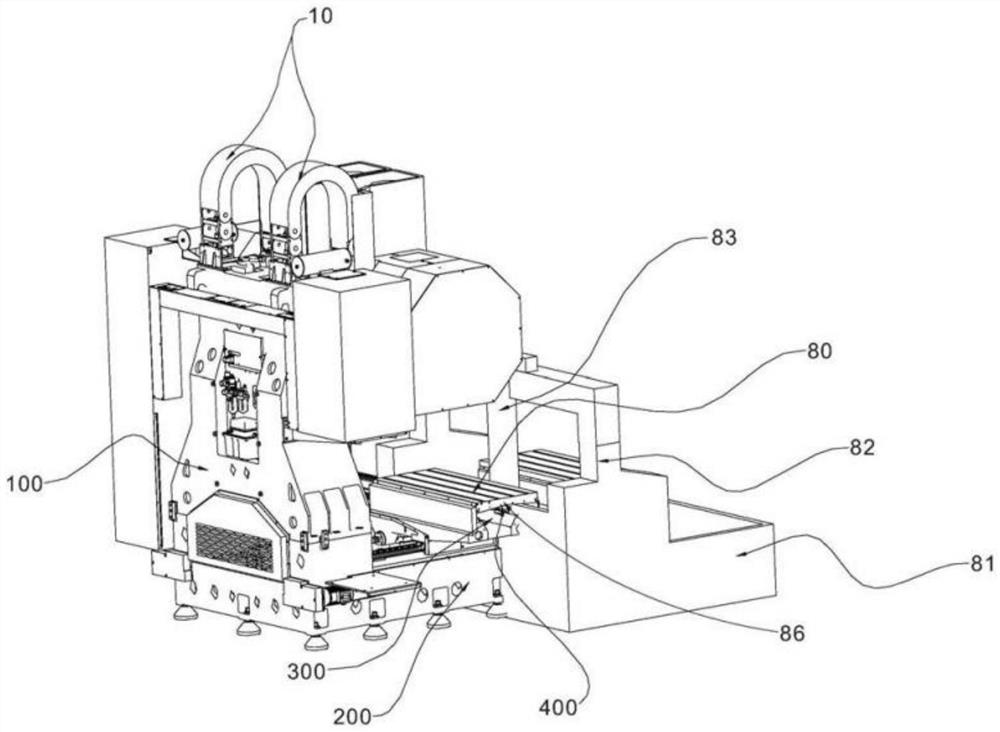

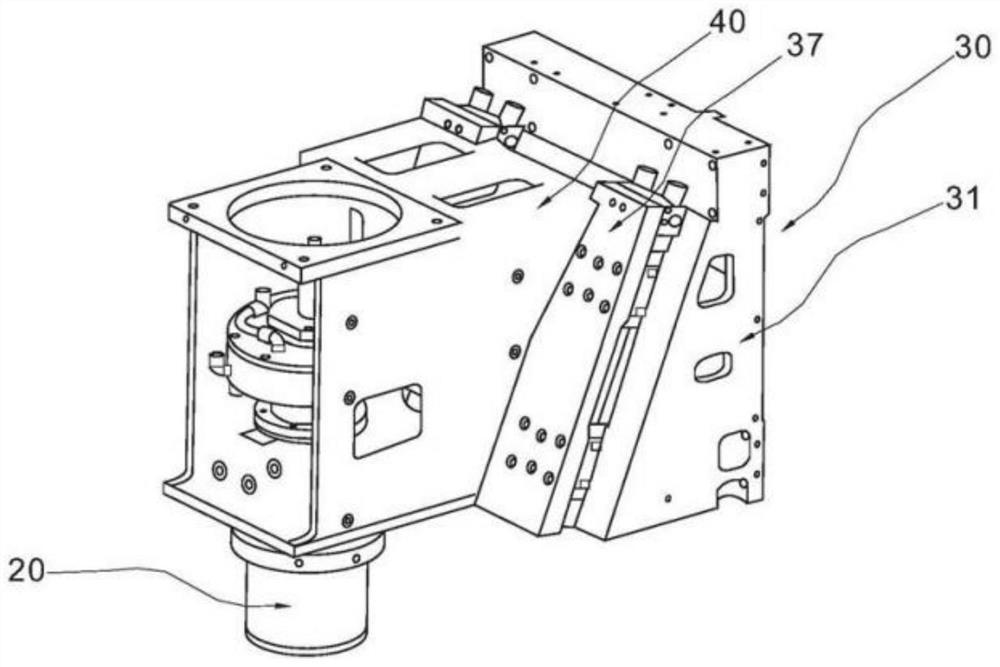

[0047] like Figure 1 to Figure 6 As shown, this embodiment provides a multi-spindle machining center with micro-motion compensation function, including a main base 200, a main column 100, a saddle 300, a worktable 400, two spindle machining units, and a workpiece pallet exchange mechanism. The main column 100 is fixed on the main base 200 and is perpendicular to the ground, the main shaft processing unit is slidably connected to the main column 100, the saddle 300 is slidably connected to the main base 200, and a Y-axis drive mechanism is connected between the saddle 300 and the main base 200 , the worktable 400 is slidably connected to the saddle 300 , and an X-axis drive mechanism is connected between the worktable 400 and the saddle 300 . The spindle machining unit includes a spindle 20 , a micro-motion compensation mechanism 30 and a unit main body 40 . The main shaft 20 is mounted on the unit main body 40 , and a Z-axis driving device 10 is provided between the main shaf...

Embodiment 2

[0050] There are three spindle machining units. The rest are the same as in Example 1.

Embodiment 3

[0052] There are four spindle machining units. The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com