Radial deep-well pump with return guide vane

A technology of anti-guide vanes and deep well pumps, applied in the direction of radial flow pumps, pumps, pump components, etc., can solve the problems of reduced production costs, high manufacturing costs, and short axial dimensions, and achieve reduced production costs and simple casting processes , The effect of small hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

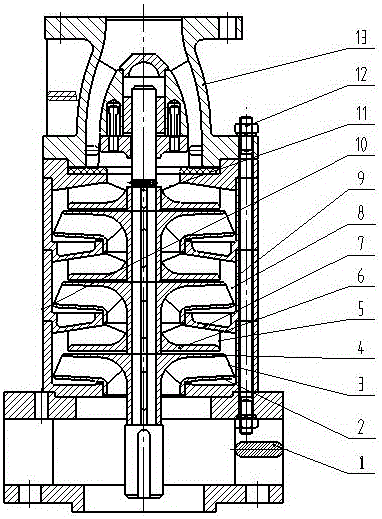

[0012] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

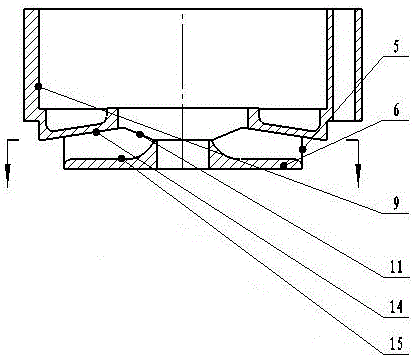

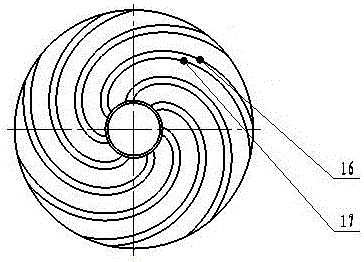

[0013] Such as Figure 1 to Figure 3 As shown, a radial anti-guide vane deep well pump is composed of more than two pairs of impellers and guide casings connected in series with a water inlet section 1 and a water outlet section 13, connected by a tie rod 12; according to the national standard GB / T2816-2002 According to the provisions of "Submersible Pumps for Wells", the outer diameter of the diversion shell must be designed to be about φ133, and the wall thickness of the diversion shell is designed to be 6 mm through strength calculation, and the outer diameter of the diversion shell is 10 minus twice the wall thickness of the diversion shell , the maximum inner diameter 9 of the diversion shell is obtained to be about φ121. According to the rated flow rate and the inlet area required by the guide vane, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com