Composite flywheel with plastic blade of engine

A technology combining flywheel and wind impeller, which is applied in the direction of engine cooling, engine components, machine/engine, etc., can solve the problems of scrapped flywheel, high brittleness of cast iron material, broken flywheel blades, etc., to reduce manufacturing cost and simplify casting process , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

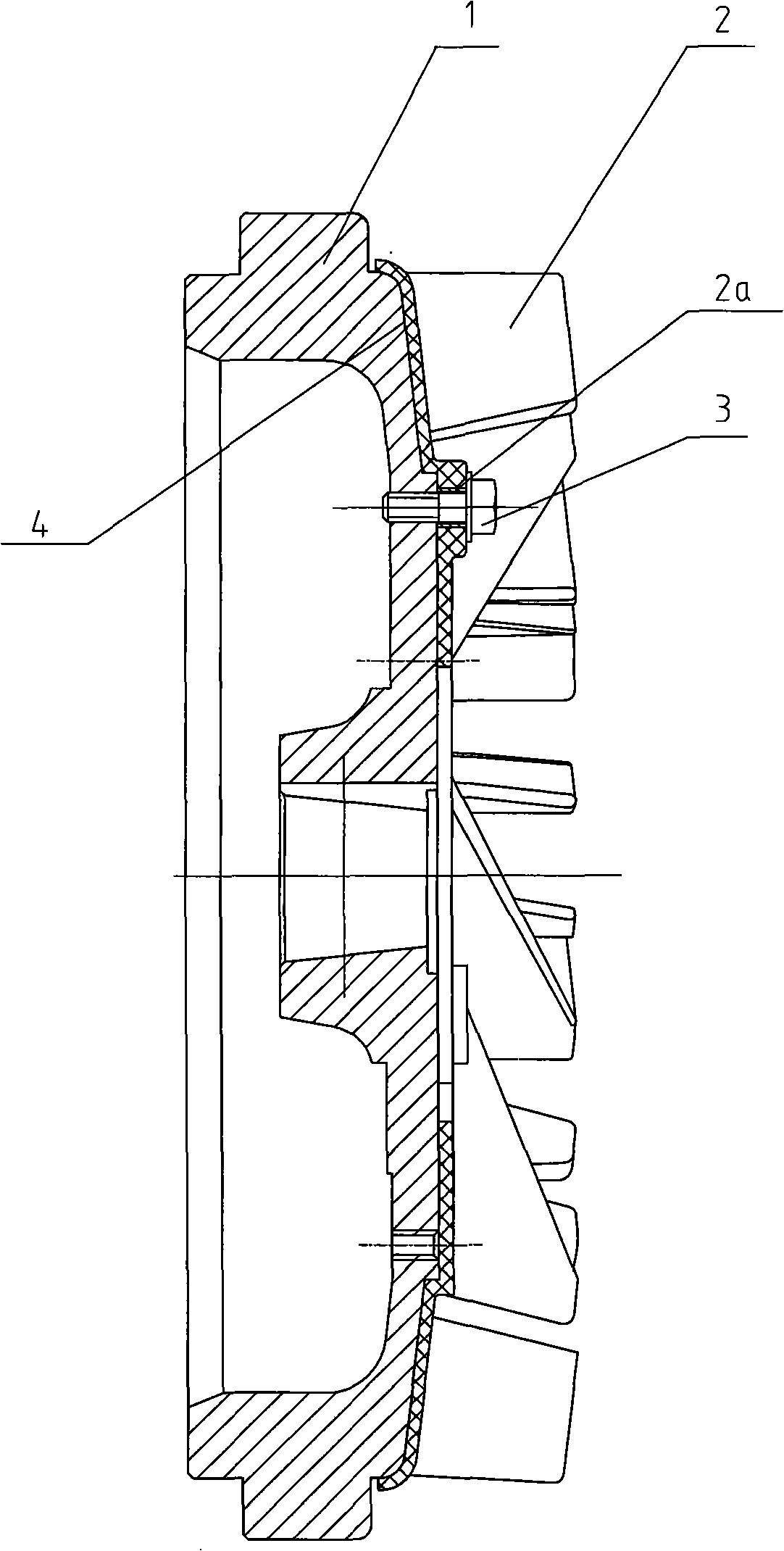

[0012] Such as figure 1 , shown in Fig. 2, mainly comprise flywheel 1, plastic wind impeller 2 (steel bushing 2a), bolt 3 etc.

[0013] In the present invention, the plastic wind impeller 2 is fastened on the screw hole of the flywheel 1 with several bolts 3 . In addition, a steel bushing 2a is cast in the screw hole of the plastic wind impeller 2 to bear the pressing force during locking. In order to prevent the wind impeller 2 from moving radially due to vibration during rotation, the flywheel 1 is processed with a positioning stop circle for the wind impeller. In addition, the two ends of the flywheel 1 and the plastic wind impeller 2 are fitted with inclined planes 4, and the same included angle ensures reliable bonding between the flywheel 1 and the plastic wind impeller 2, effectively preventing the plastic wind impeller 2 from moving radially....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com