Stainless steel sensor faucet and production method thereof

A stainless steel and faucet technology, applied in the field of faucets, can solve the problems of poor quality, small cavity opening, troublesome operation, etc., and achieve the effects of simple casting process, reduced production cost, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

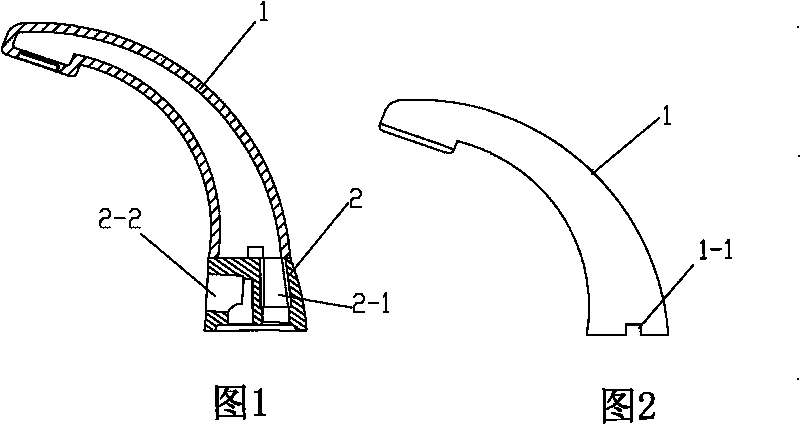

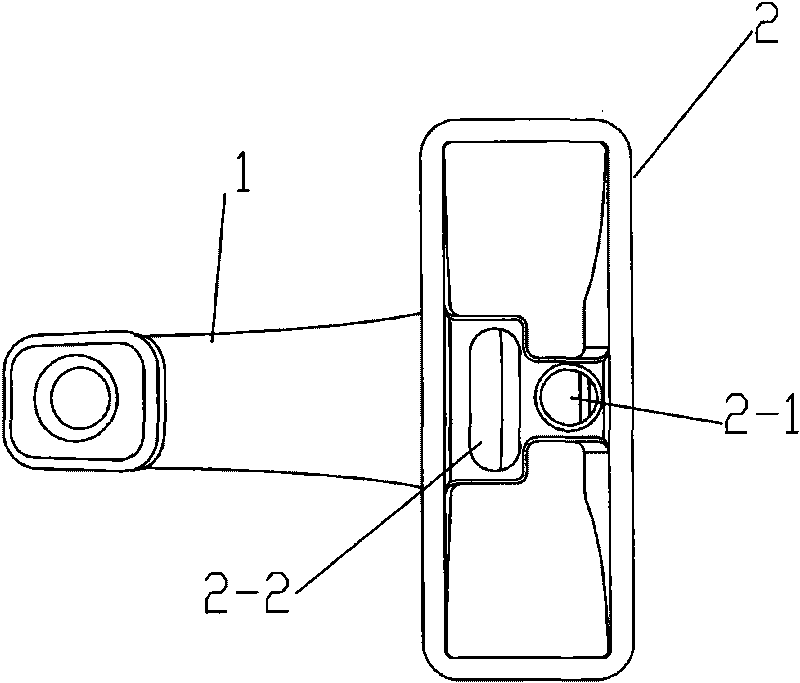

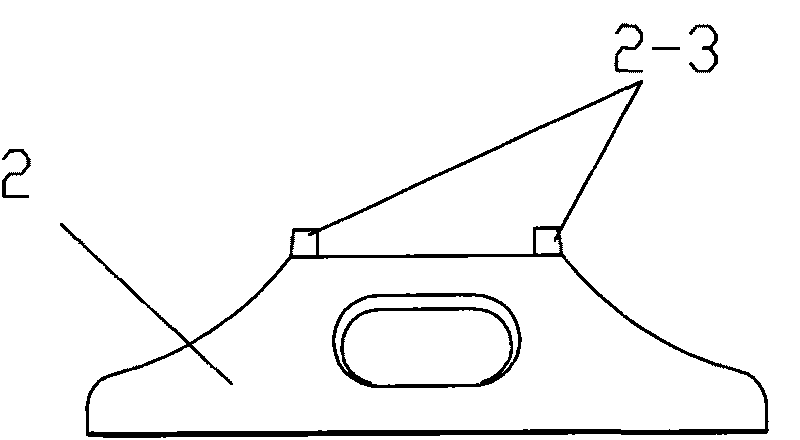

[0031] Refer to the accompanying drawings: This stainless steel induction faucet is cast from stainless steel as a whole. It includes a water outlet pipe 1 and a base 2, wherein the water outlet pipe 1 is in the shape of an elbow, and the base 2 is provided with a water passage chamber 2-1 and an installation chamber 2-2 for placing sensors, and the water outlet pipe 1 and the base 2 are divided into Asana structure, and the two are welded together. A bayonet 1-1 is provided at the bottom of the outlet pipe 1, and a protrusion 2-3 matching the bayonet 1-1 is provided on the base 2, and the protrusion 2-3 is snapped into the bayonet 1-1.

[0032] The production method of the above-mentioned stainless steel induction faucet comprises the following steps:

[0033] 1) Mold opening: According to the overall faucet, it is segmented into outlet pipe 1 and base 2, which are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com