Motor fixing base

A technology of motor fixing and bottom plate, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of equipment temperature increase, affecting equipment service life, increasing friction between shaft and bearing, etc., so as to avoid shear damage. , Simple structure, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

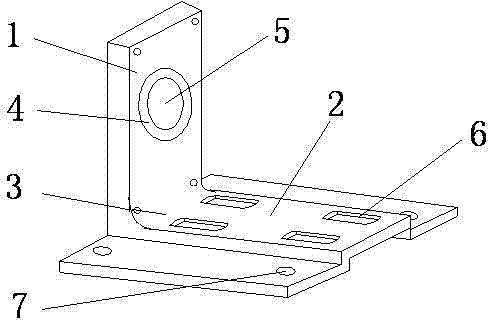

[0011] Such as figure 1 As shown, the motor fixing seat includes a side plate 1 and a bottom plate 2 connected with the side plate 1. The side plate 1 is provided with a through hole 5 suitable for the motor spindle, and the motor is evenly distributed around the through hole 5. Mounting holes, the bottom plate 2 is provided with mounting holes.

[0012] Further, the mounting holes on the bottom plate 2 are all waist-shaped holes.

[0013] Further, there is an arc-shaped transition surface 3 between the side plate 1 and the bottom plate 2 .

[0014] The motor fixing seat of the present invention has simple structure and firm fixing. The installation hole on the bottom plate adopts a waist-shaped hole, which can adjust the position of the motor; there is an arc-shaped transition surface between the side plate and the bottom plate, which makes the motor fixing seat more shock-resistant. The place where the plates are connected is not easily sheared due to long-term vibration.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap