Simple juicer

A juicer and simple technology, applied in the field of simple juicer, can solve the problems of incomplete pressing, difficult to finish drinking at one time, laborious juicing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

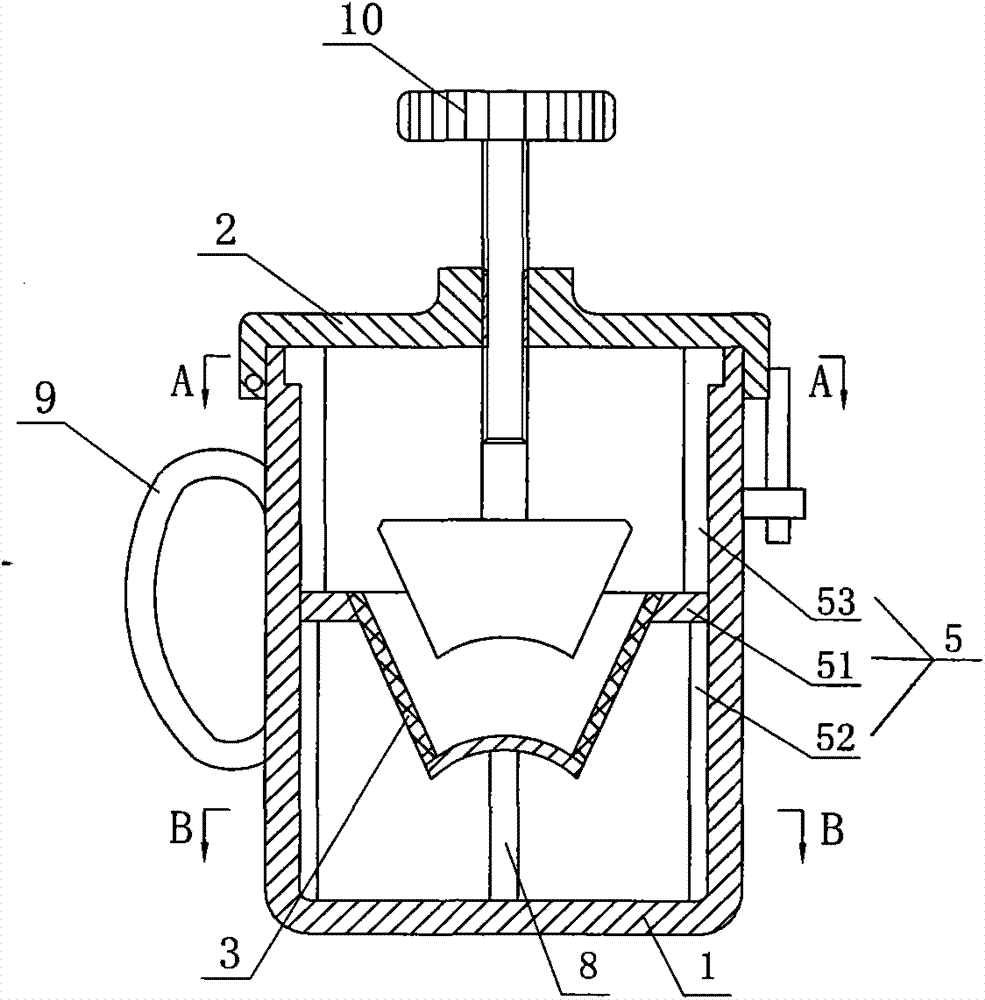

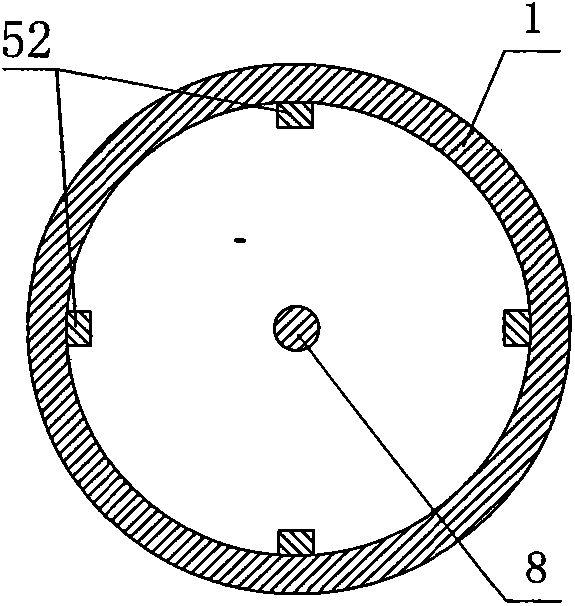

[0014] Such as figure 1 The shown simple juice press includes a tank body 1 made of stainless steel and with an open top. The top of the tank body 1 is hinged with an upper cover 2 locked by a locking device. The locking device is an existing Mechanism, not repeating it here, the filter screen 3 with small bottom and tapered setting is housed in the tank body 1 cavity, the top opening of the filter screen 3 and the bottom opening are sealed by the arc-shaped bottom plate 4 protruding upwards, filtering The edge of the opening at the top of the net 3 is connected to the inner cavity of the tank body 1 through a bracket 5, and the upper cover 2 is screwed with a spinning rod 6 extending into the tank body 1, and the inner extension end of the spinning rod 6 is fixedly connected with a A spinning head 7 adapted to the shape of the filter screen cavity.

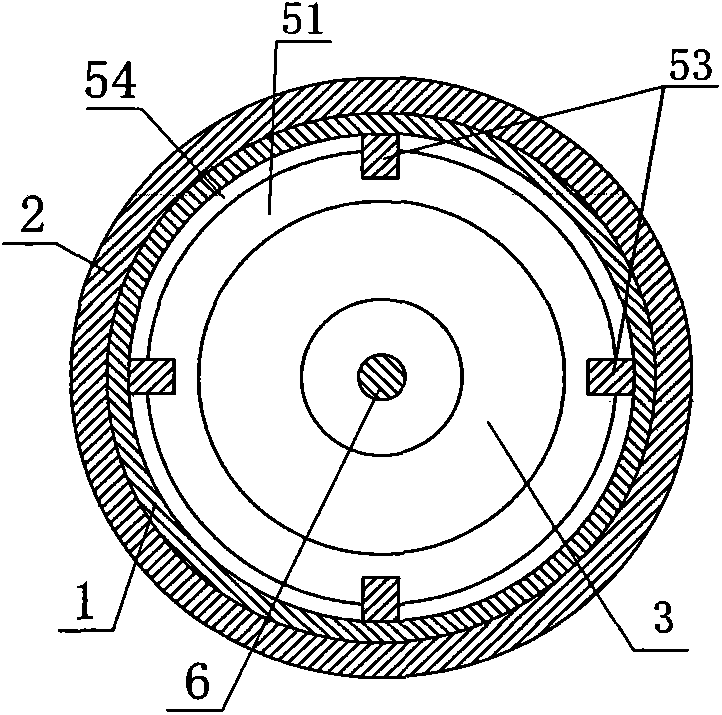

[0015] Such as figure 1 and figure 2 As shown, the support 5 includes an annular support 51 affixed to the edge of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com