Automobile left and right fender stamping technology and automobile left and right fender drawing die

A technology of fenders and sub-boards, which is applied in the stamping process of left and right fenders of automobiles and the field of drawing dies, which can solve the problems of low material utilization, low production efficiency, and high cost, so as to reduce production costs and improve production efficiency , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

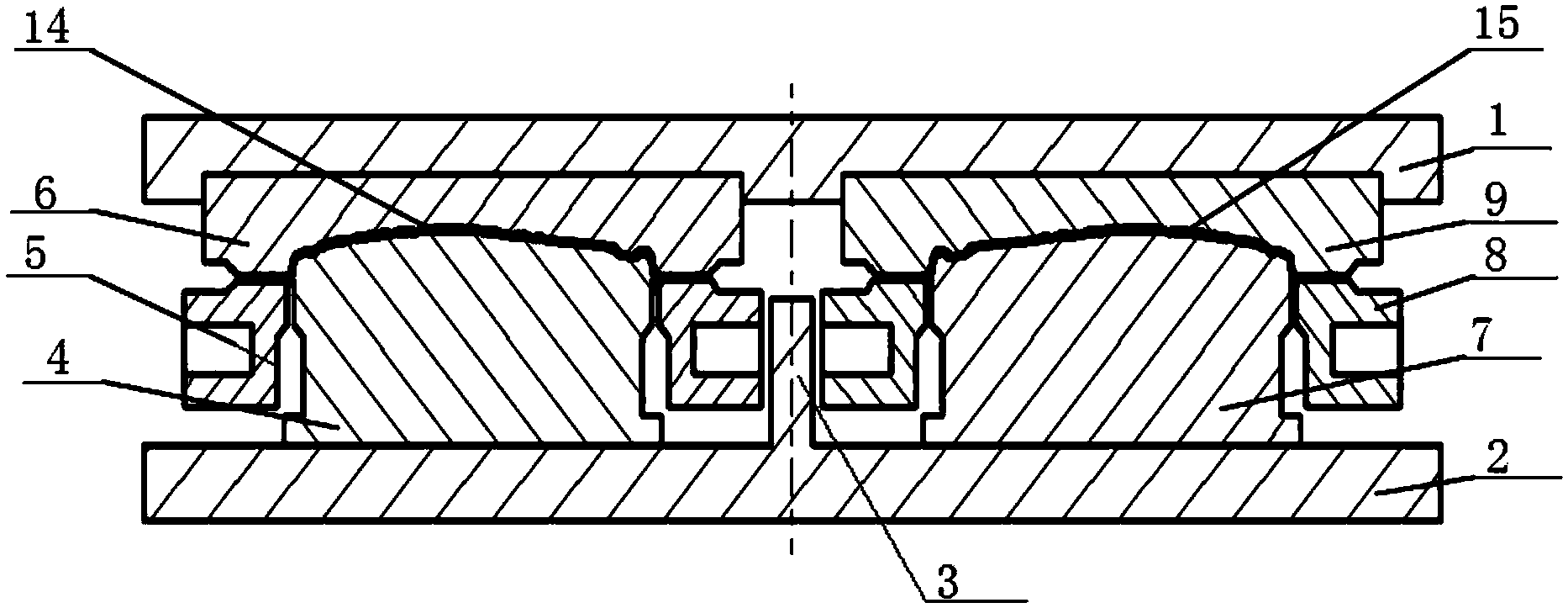

[0018] like figure 2 As shown, a drawing mold structure for the left and right fenders of an automobile includes an upper template 1 and a lower template 2, the upper middle of the lower template 2 is provided with a partition 3, and the left side of the partition 3 is provided with a left punch 4. The outer periphery of the left punch 4 is covered with a left binder ring 5, and a left die 6 is arranged above the left punch 4. The shapes of the left punch 4 and the left die 6 match the shape of the left fender, The right side of the dividing plate 3 is provided with a right punch 7, the outer periphery of the right punch 7 is covered with a right binder ring 8, the top of the right punch 7 is provided with a right die 9, and the right punch 7 and the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap