Fixture for clamping steam inlet and outlet sides of intermediates of blade roots during milling

An intermediate, steam-side technology, applied in the field of clamping fixtures for milling blade root intermediates in and out of the steam side, can solve the problems of wasting manpower, complicated operations, and a large number of fixtures, and achieves low manufacturing cost, simple operation, and easy maintenance. maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

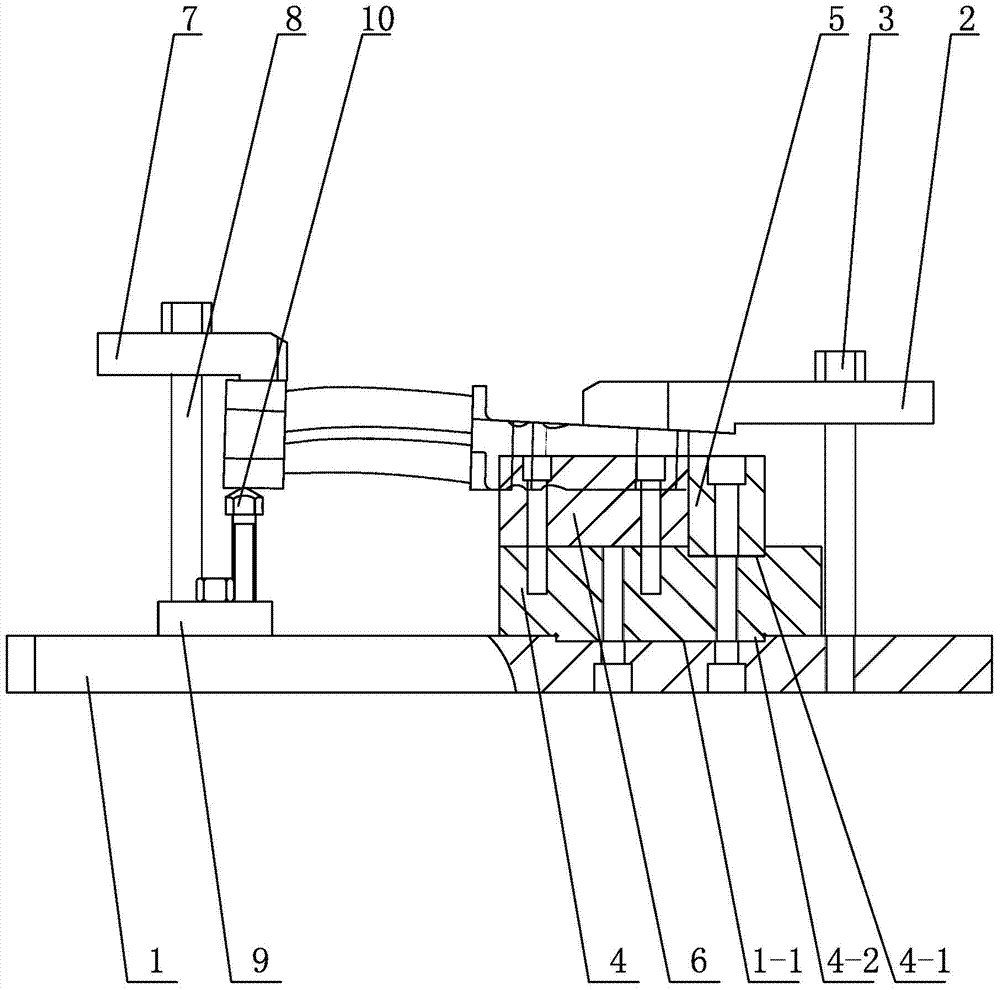

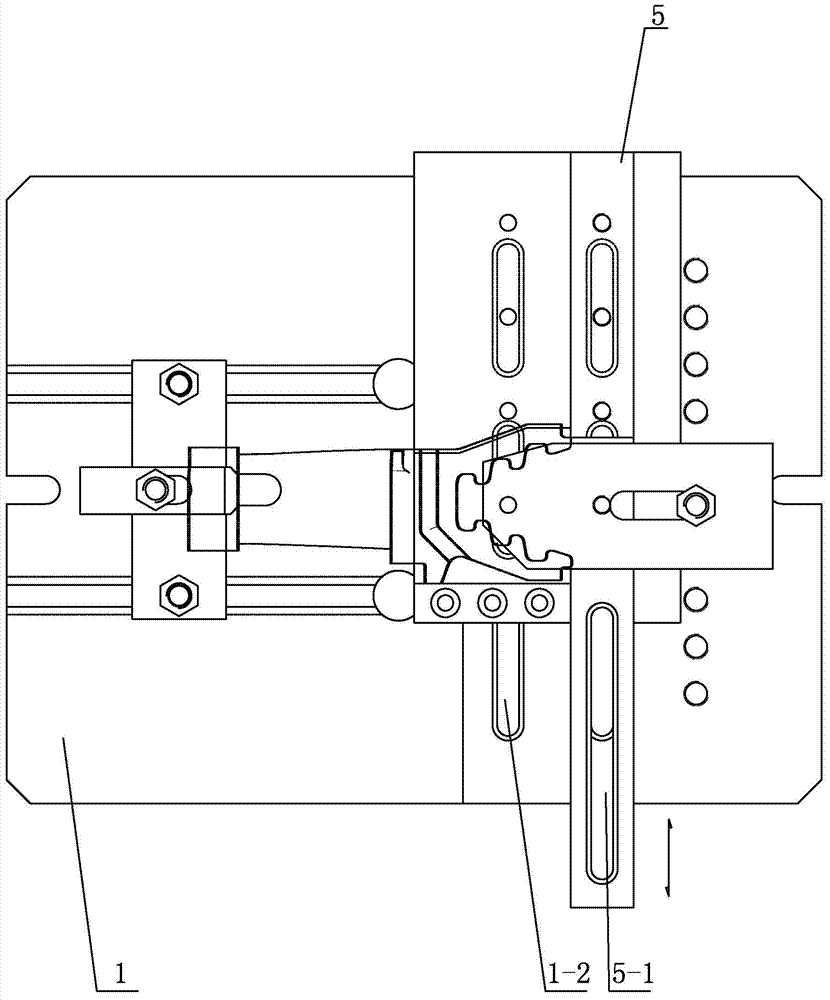

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a fixture for clamping the inlet and outlet steam sides of the milling blade root intermediate body described in this embodiment includes a bottom plate 1, a slope pressure plate mechanism, a flat pressure plate 2, a first double-ended stud 3, a guide slider 4, a positioning Slider 5 and baffle plate 6, bottom plate 1 is arranged horizontally, the lower end of first double-ended stud 3 is inserted on the upper surface of bottom plate 1, and the upper end of first double-ended stud 3 is connected with platen 2, and platen 2 The lower surface of the bottom plate is parallel to the upper surface of the bottom plate 1, the guide slider 4 is arranged on the upper surface of the bottom plate 1, and the guide slider 4 is located under the flat plate 2, and the positioning slider 5 and the baffle plate 6 are installed side by side through a plurality of bolts On the upper surface of the ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. The slope clamping mechanism of the clamp for the inlet and outlet steam side of the milling blade root intermediate in this embodiment includes the slope clamping plate 7, the second double-ended stud 8, the base 9 and the hexagonal head support 10, The base 9 is installed on the upper surface of the base plate 1, the lower end of the second double-ended stud 8 is inserted on the base 9, the slope pressing plate 7 is installed on the upper end of the second double-ended stud 8, and the lower end of the slope pressing plate 7 The surface is parallel to the upper surface of the bottom plate 1 , the hexagonal head support 10 is installed on the upper surface of the base 9 , and the hexagonal head support 10 is located below the slope pressing plate 7 .

[0009] The technical effect of this embodiment is: such arrangement enables blades of different models and types to be ac...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the guide slider 4 of the clamp for the inlet and outlet steam side of the milling blade root intermediate described in this embodiment is a cuboid, and the upper surface of the guide slider 4 is provided with a first rectangular chute 4-1, and The first rectangular chute 4-1 is parallel to the centerline of the guide slider 4 along the longitudinal direction along the length square centerline, and the positioning slider 5 is inserted in the first rectangular chute 4-1.

[0011] The technical effect of this embodiment is: such setting enables the positioning slider 5 to be adjusted at any time according to the shape and position of the blade, ensuring the accuracy of installation. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com