Heating furnace cooling control system and control method

A technology of cooling control and heating furnace, which is applied in the field of steel rolling heating furnace, can solve the problems of threatening the safety of heating furnace operators, explosion, deformation, etc., achieve the effect of small investment, quick effect, and ensure normal cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

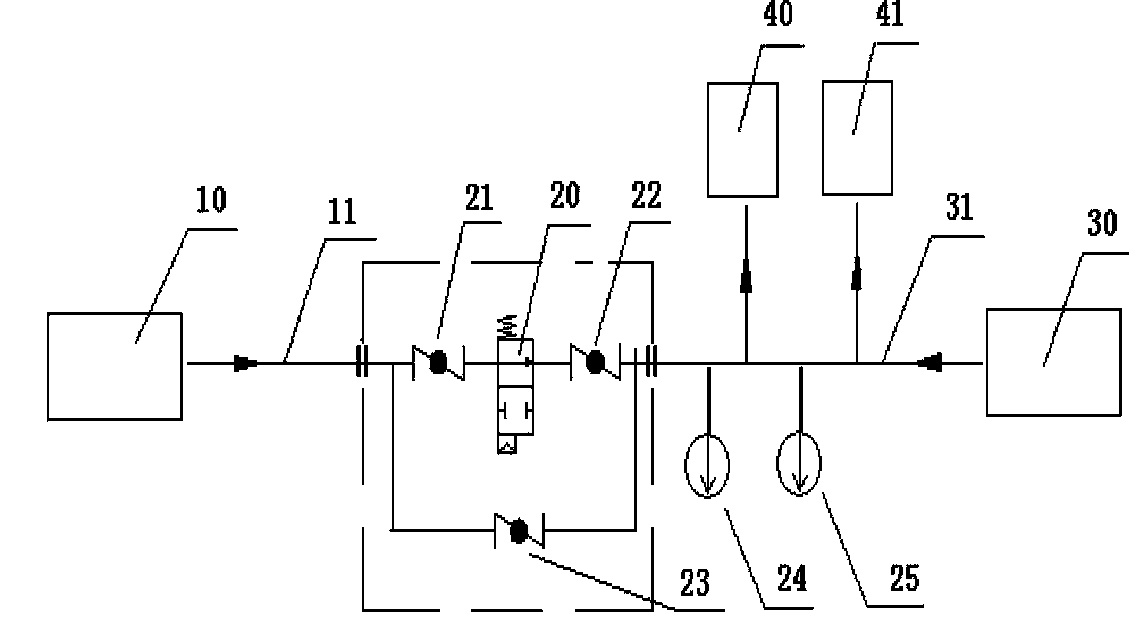

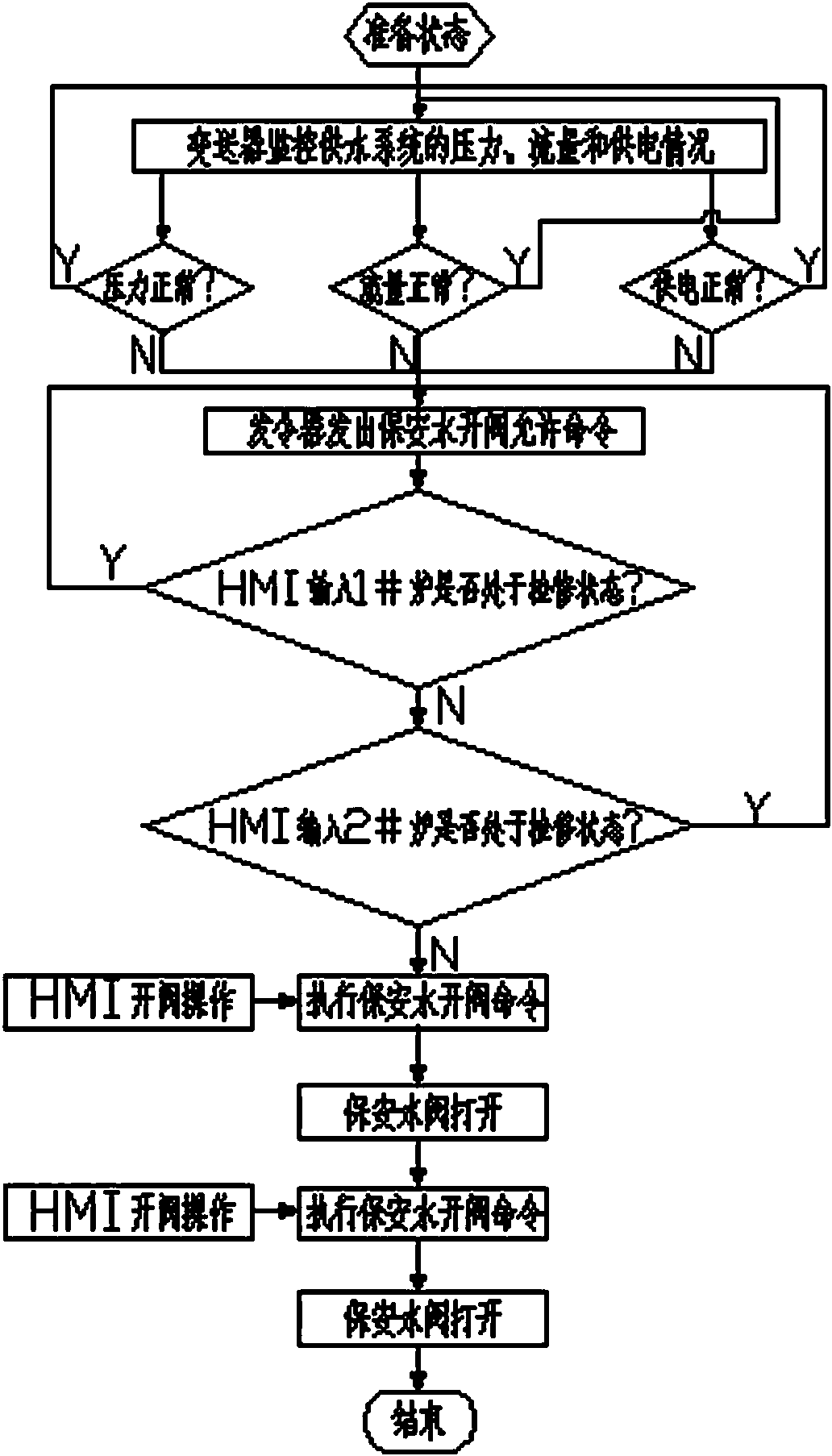

[0031] Embodiment 1: In the case of normal production, the heating furnace 40, 41 cooling water supply system 30 water pump is damaged, and the pressure is 1 bar, which is lower than the set value. First, the pressure transmitter 24 and the flow transmitter 25 are used for monitoring The water supply pressure, flow rate and power supply of the heating furnace 40, 41 cooling control system; the pressure transmitter 24 is used to judge whether the pressure of the cooling water main pipe supplied to the heating furnace 40, 41 is maintained within the set range, and the pressure is low due to the damage of the water pump. If the pressure is lower than the set value, so the pressure is not within the set range, then continue to monitor the heating furnace 40, 41 cooling control system water supply pressure, flow and power supply situation, and the next step can only be entered after the water pump is repaired.

Embodiment 2

[0032] Embodiment 2: In the case of normal production, the heating furnace 40, 41 is powered off, and the power supply is abnormal. First, the pressure transmitter 24 and the flow transmitter 25 are used to monitor the power supply of the heating furnace 40, 41; , 41 power outage, so do not enter the next step, continue to get back to the state of the monitoring heating furnace 40, 41 cooling control system, after the power supply is restored, the next step can be entered.

Embodiment 3

[0033] Embodiment 3: When the cooling water system of the heating furnace is abnormal and the valve cannot be opened automatically, the command to open the valve can be manually issued on the man-machine communication interface to execute the command to open the safety water valve.

[0034] The present invention has the characteristics of small investment, quick effect and convenient operation, and can not be disturbed by external conditions when the circulating cooling water system of the heating furnace cannot supply water normally due to various reasons such as power failure, damage to the water pump and leakage of the pipe network 11, etc. Ensure that the security water is put in in time, and ensure the normal cooling of the heating furnace 40, 41 to ensure the safety of the furnace. It is suitable for the cooling water system of the heating furnace in the hot rolling plate factory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com