Low-noise dry-type iron core reactor assembling process

An iron core reactor and assembly process technology, applied in the direction of circuits, electrical components, inductors with magnetic cores, etc., can solve the lack of vacuum casting method, weak bonding surface, and large noise at the joints between the iron core column and the iron yoke And other problems, to achieve good application prospects, improve product performance, improve the effect of joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

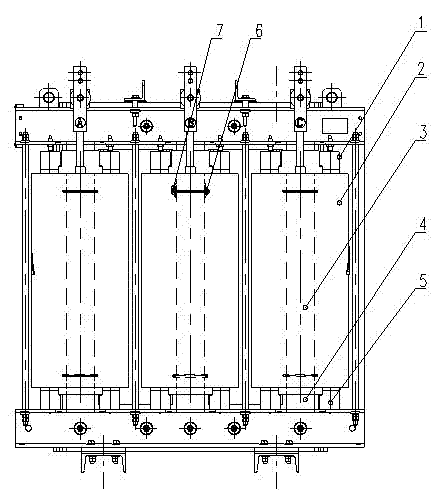

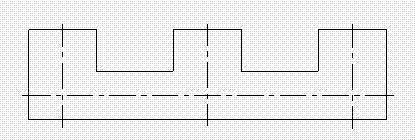

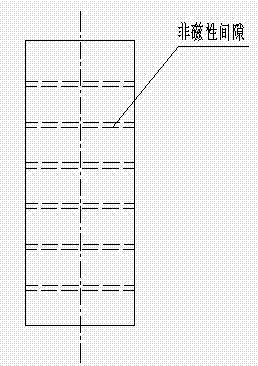

[0034] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the low-noise dry-type iron-core reactor mainly includes an upper pad 1, a coil 2, a core column 3, a mountain-shaped iron yoke 4, a lower pad 5, and a pouring conduit 6 (see Figure 7 ), production aids for the rubber belt 7.

[0035] The assembly of the reactor includes the following steps:

[0036] ①Prepare the "mountain"-shaped iron yoke 4, discus and the core column 3, coil 2, pads 1, 5 and other components composed of the non-magnetic gap, and conduct semi-finished product tests to determine the distribution of the non-magnetic gap on the core column ;

[0037] ② Vacuum pour the iron core column with the non-magnetic gap placed through epoxy resin;

[0038] ③ Seal the upper end of the lower iron yoke: the method is: (1) Use the upper end of the "mountain"-shaped lower iron yoke as a support, put the iron yoke into a flat-bottomed resin tank; (2) Fill the tank with epoxy resin , the dosage must ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com