Equipment for intermittent vacuum casting of large steel ingots with multiple sliding nozzle packages and special diversion tubes

A technology of sliding nozzle and vacuum pouring, which is applied in casting equipment, metal processing equipment, casting molten material containers, etc., and can solve problems such as plug head falling off, plug rod sleeve brick thickness is limited, normal work is affected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

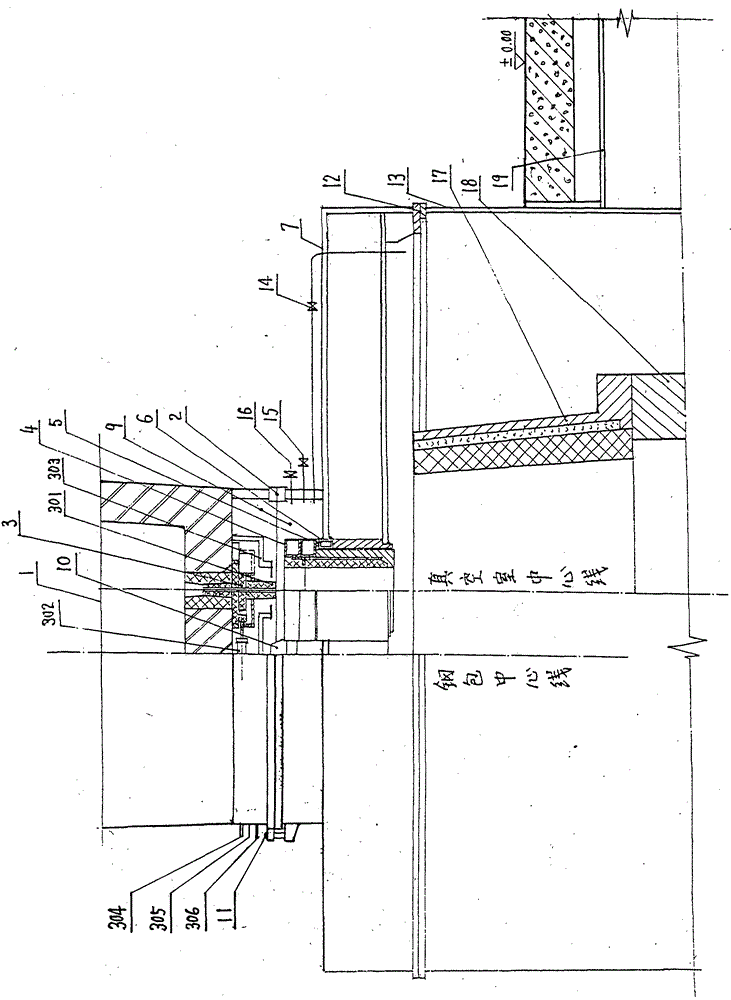

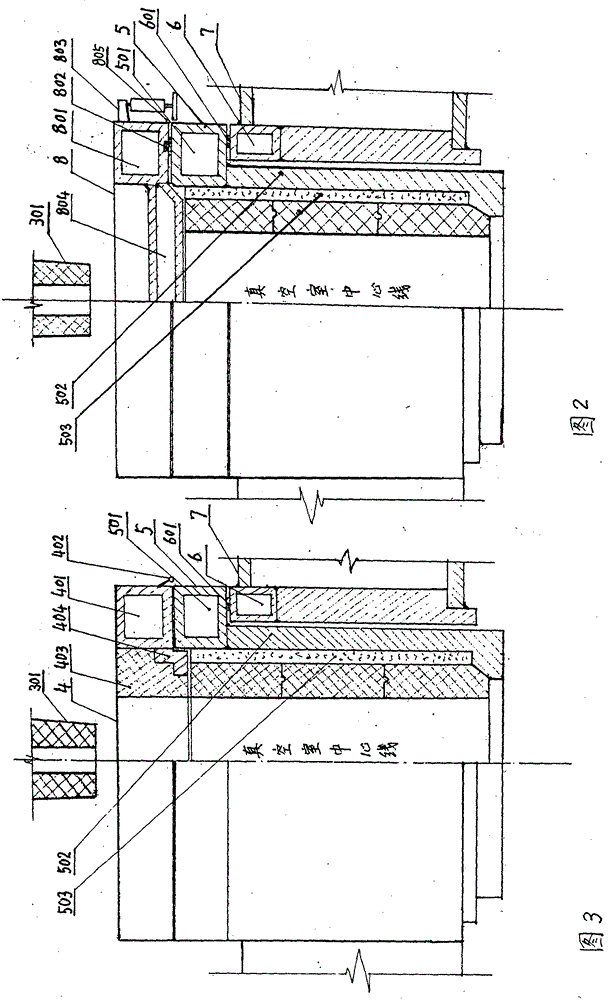

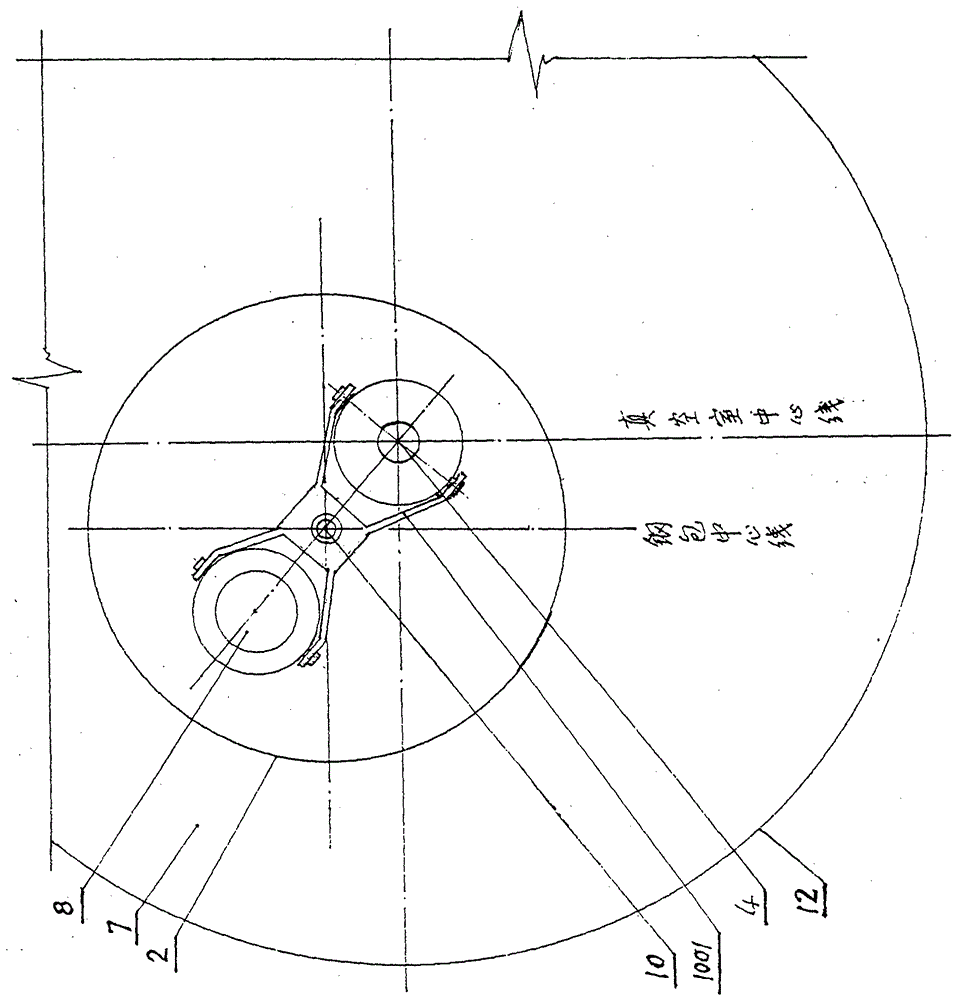

[0101] (1). Transformation work: According to the requirements in the composition of the equipment of the present invention, refer to the attached figure 1 , 2, 3, 4 and reference signs, according to specific circumstances, design, manufacture or modify the following items:

[0102] 1. Modify the lower part of the ladle shells of multiple existing LF refining sliding nozzles into ladles (1), add a raised flange A (2), and install nozzles (3) with opening and closing mechanisms and vent plugs, including The hydraulic cylinder and the heat protection device are equipped with a quick connector on the outer side of the flange A (2), and the hydraulic pipeline extending from the flange A (2), the supply Ar pipeline, and the cooling water pipeline are connected to their respective sources.

[0103] 2. An increased flange A (2) is added to the upper part of the vacuum cover (7), a transposition device (10) and a water-cooled connecting beam are added, and an upper guide tube (4) is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com