A kind of preparation method of tea saponin acrylic acid polymer and its application in coal water slurry

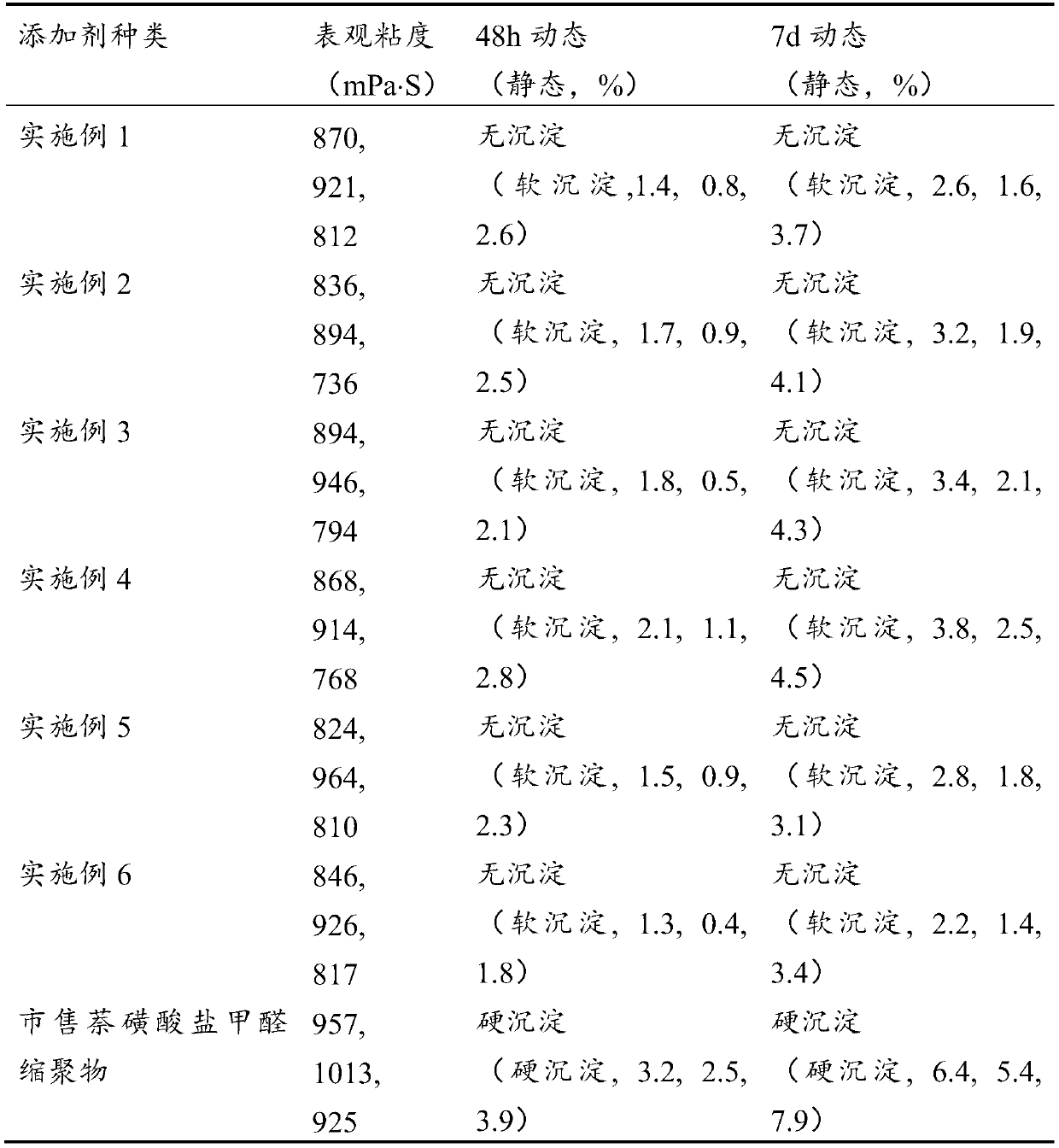

A technology of tea saponin acrylic acid and polymer, which is applied in the field of coal water slurry additives, can solve the problems of coal water slurry system such as easy sedimentation, weak action force, good hydrophilicity, etc., and achieve easy control of reaction conditions, wide application range, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix 100g tea saponin with 100g methallyl alcohol polyoxyethylene ether (average molecular weight 1200), add 200g water to dissolve, then add 0.1g ammonium persulfate and mix evenly, add dropwise 10g acrylic acid, 10g sodium propylene sulfonate and 0.02 g thioglycolic acid mixture, reaction time 2h. After cooling to room temperature, the pH of the system was adjusted to 6 with 20% sodium hydroxide, and vacuum-dried at 70° C. for 3 hours to obtain 216 g of tea saponin acrylic acid polymer.

Embodiment 2

[0022] Mix 100g of tea saponin with 300g of methallyl alcohol polyoxyethylene ether (average molecular weight 2400), add 2000g of water to dissolve, then add 4g of potassium persulfate and mix evenly, add dropwise 30g of acrylic acid, 30g of sodium propylene sulfonate and 0.3g of Mercaptopropionic acid mixture, reaction time 6h. After cooling to room temperature, the pH of the system was adjusted to 8 with 40% potassium hydroxide, and vacuum-dried at 70° C. for 6 hours to obtain 462 g of tea saponin acrylic acid polymer.

Embodiment 3

[0024] Mix 100g of tea saponin with 200g of methallyl alcohol polyoxyethylene ether (average molecular weight 1200), add 900g of water to dissolve, then add 1.5g of ammonium persulfate and mix evenly, add dropwise 40g of acrylic acid, 20g of sodium propylene sulfonate and 0.1 g thioglycolic acid mixture, reaction time 4h. After cooling to room temperature, the pH of the system was adjusted to 7 with 30% sodium hydroxide, and vacuum-dried at 60° C. for 4 hours to obtain 358 g of tea saponin acrylic acid polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com