Chip installing device with vertical parts driven by sliding block and provided with elastic materials

A chip mounting and vertical part technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that the chip efficiency cannot reach the expected value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

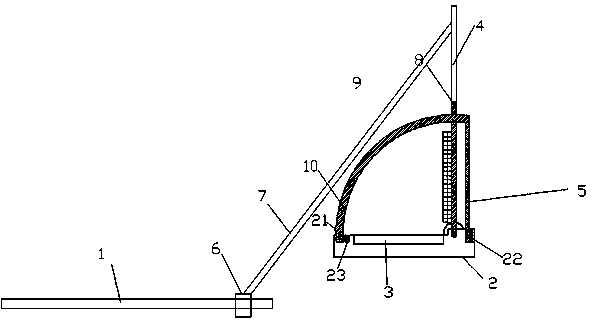

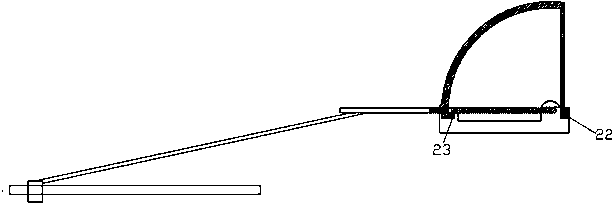

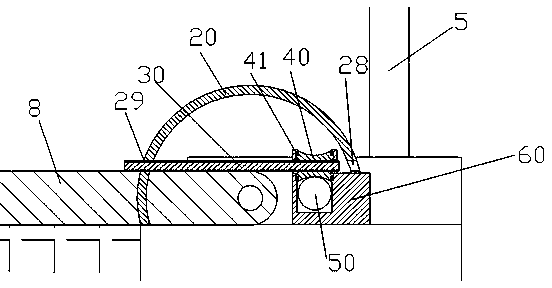

[0016] A chip mounting device with elastic material in the vertical part driven by a slider, comprising a mounting seat 2 having a chip mounting groove 3 for mounting a chip; the mounting seat 2 is placed in the chip mounting groove The right side of 3 is hinged with the lower end of the chip presser 8 through a hinge shaft, and the front side of the chip presser 8 is used to join the chip 9 in the initial state and press the chip 9 into the chip of the mounting seat 2 in the final state. Install in slot 3.

[0017] Two through holes 81, 82 are arranged side by side in the direction of the hinge axis at the upper end of the chip presser 8, which are respectively passed through by two presser guide rods, and the chip bonding area on the chip presser 8 is located at the two Between the through holes 81 and 82, the two platen guide rods have an arc portion 10 and a vertical portion 5, wherein the center of the arc portion 10 is located at the hinge axis, and the arc portion 10 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com