Track system floating vibration isolation structure

A track and floating technology, applied in the direction of tracks, roads, buildings, etc., can solve problems such as inability to meet requirements, and achieve the effects of preventing high-frequency vibration short-circuit, improving balance, and improving vibration isolation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

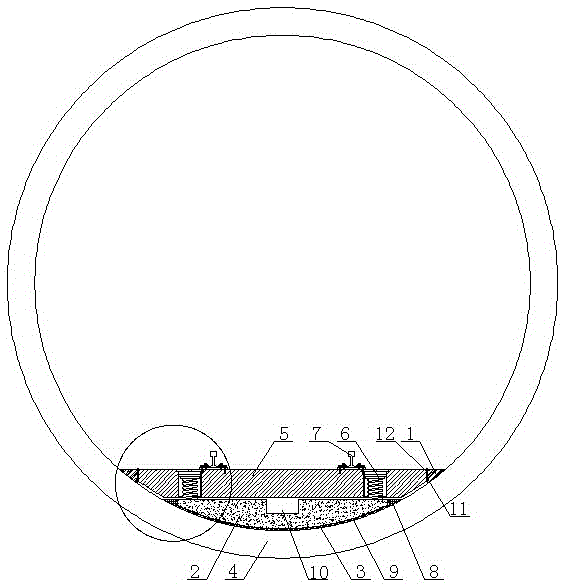

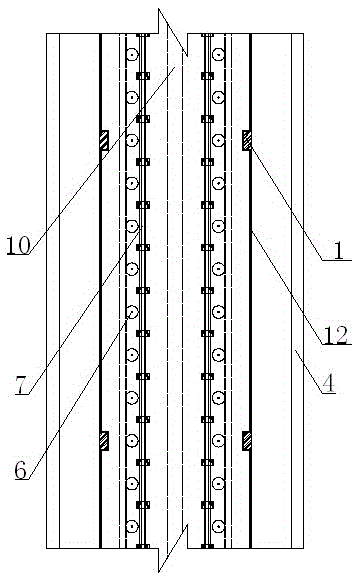

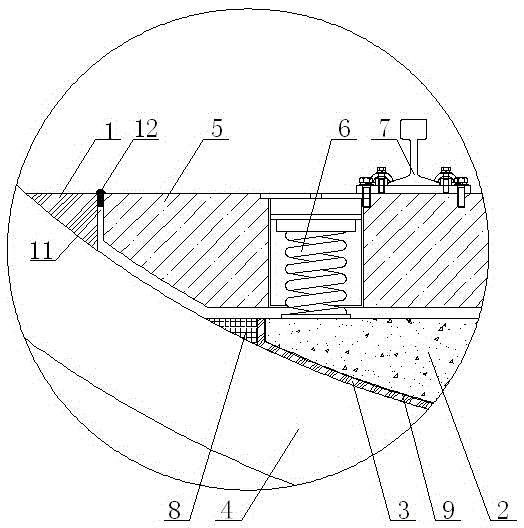

[0017] exist figure 1 , 2 , In the embodiment shown in 3, a floating vibration isolation structure of a track system is composed of a bottom floating building vibration isolation system, an upper layer steel spring floating slab track bed vibration isolation system and a damping limiter 1. The bottom floating vibration isolation system is composed of the foundation rigid mass block 2 and the floating rubber vibration isolation pad 3. The floating rubber vibration isolation pad 3 is arranged between the tunnel shield segment inner wall 4 and the foundation rigid mass block 2; the upper layer steel spring The floating slab track bed vibration isolation system is composed of a rigid slab track bed 5 and an adjustable preload damping steel spring vibration isolator 6, the track 7 is installed on the rigid slab track bed 5, and the rigid slab track bed 5 has a built-in adjustable preload damping steel spring vibration isolation The device 6, the adjustable preload damping steel sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com