A Buried Oil Pipeline Leakage Characteristic Experimental System

An experimental system and oil pipeline technology, which is applied in the field of buried oil pipeline leakage characteristic experiment system, can solve the problems of narrow application range, poor convenience, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

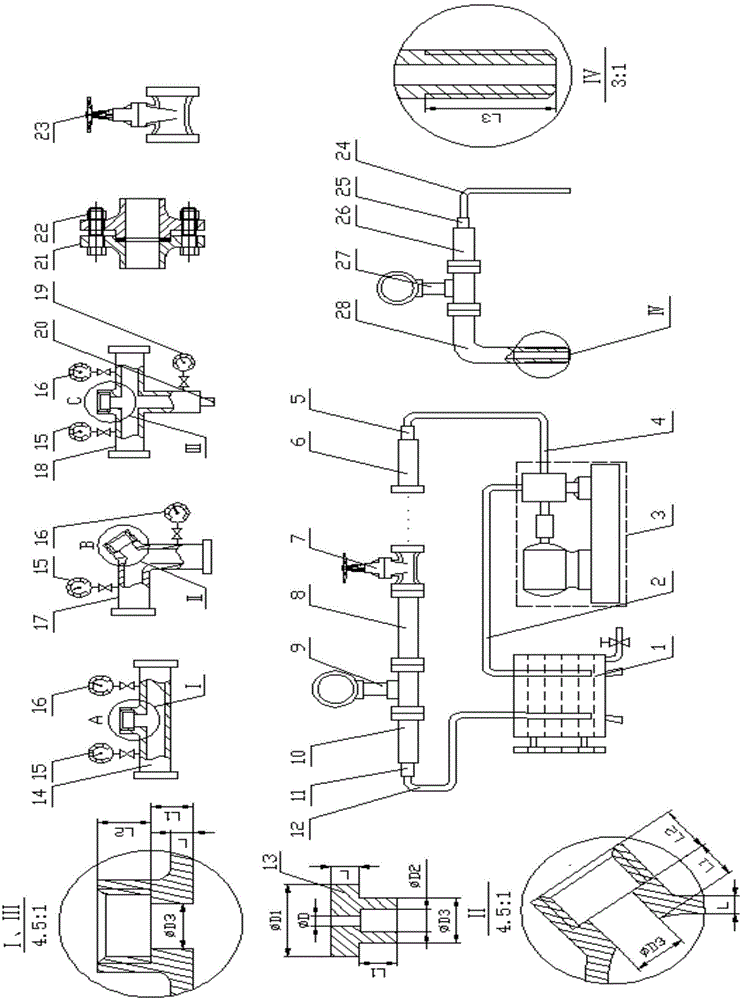

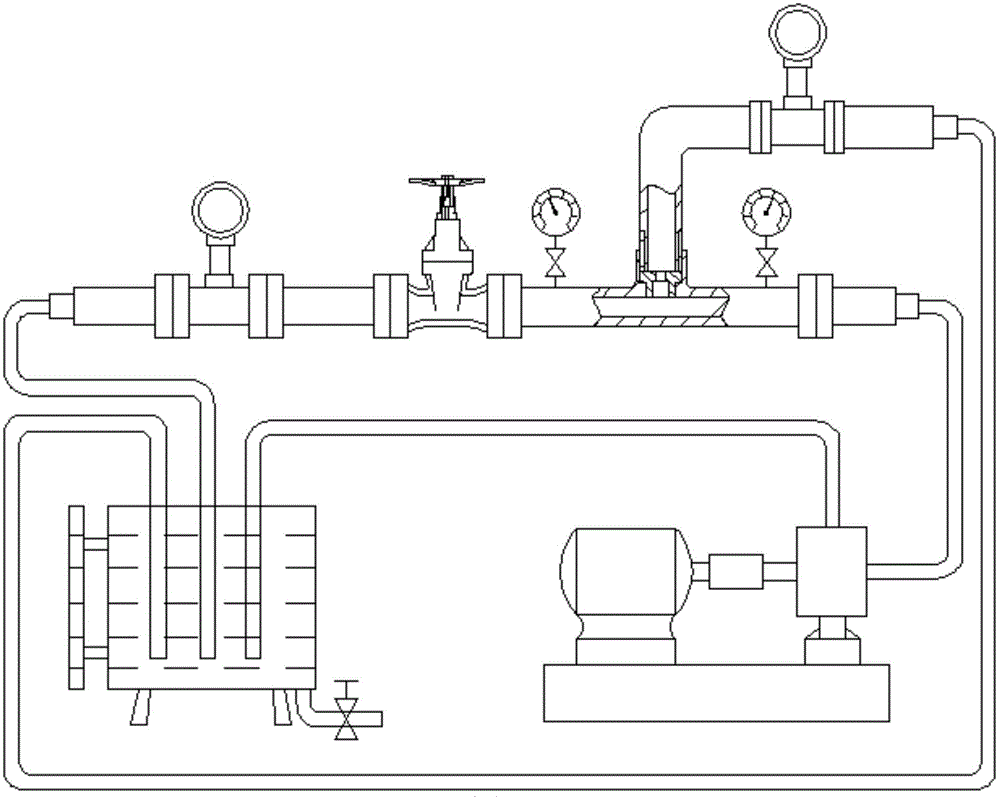

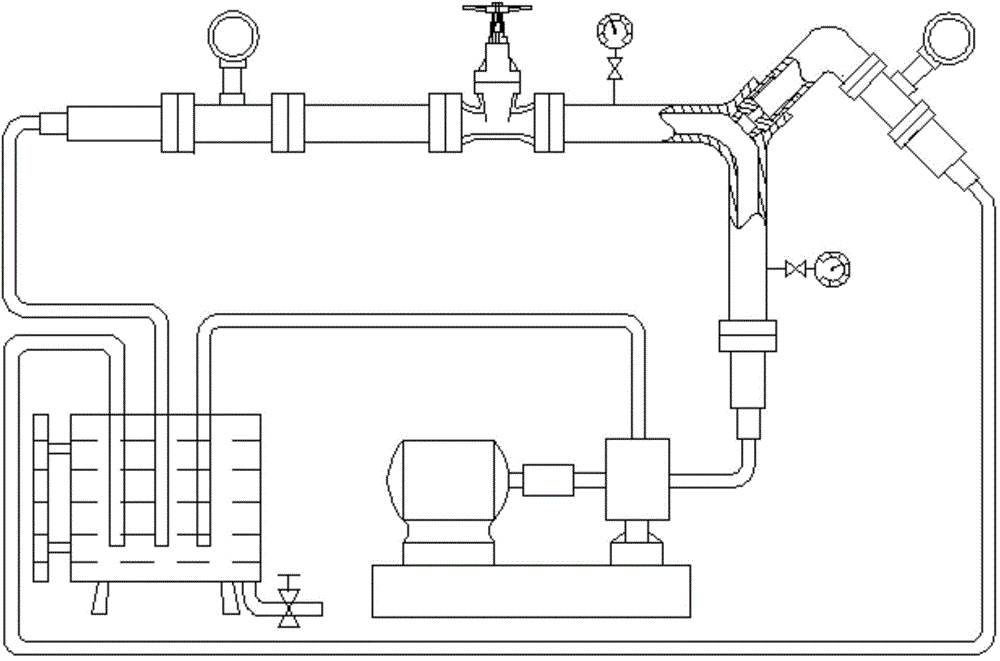

[0022] Build the main circuit of the straight pipe leakage characteristic experiment system, and conduct the straight pipe leakage characteristic experiment according to the following steps:

[0023] 1. Place the buckle 13 of a certain aperture in the leakage port A of the straight pipe 14, and press it to death with the top pressure elbow 28;

[0024] 2), the leakage circuit of the straight pipe leakage characteristic experiment system is connected, and the water supply pump 3, the water outlet mass flowmeter 9 and the leakage outlet mass flowmeter 27 are powered on;

[0025] 3) Start the water pump 3, adjust the pressure regulating valve 7, observe the readings of the pressure gauge I15 and pressure gauge II16 until the set pressure. After a period of time, start to record the indication value of the mass flow meter 27 at the leak port, and record it once every other period of time;

[0026] 4) Adjust the pressure regulating valve 7 to stabilize the system at other pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com