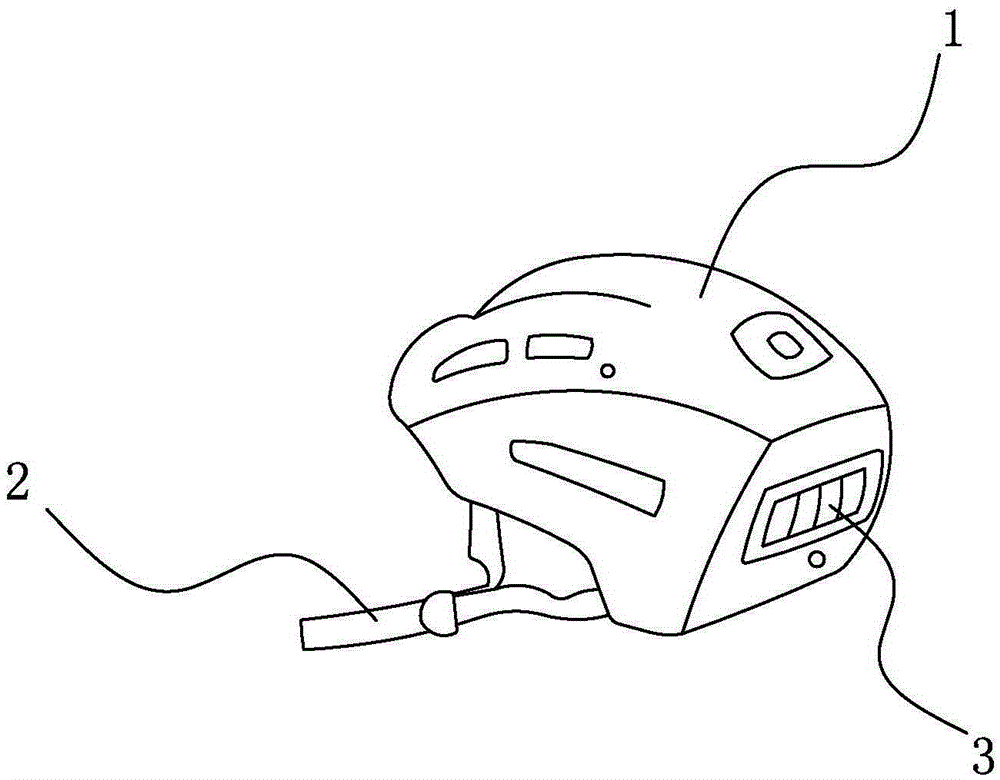

An intelligent safety helmet with a safety warning function

A safety warning and helmet technology, applied to helmets, helmet covers, clothing, etc., can solve the problems of cumbersome production process, poor reflective effect of reflective shell, etc., and achieve the effect of simple production process, improved warning effect, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

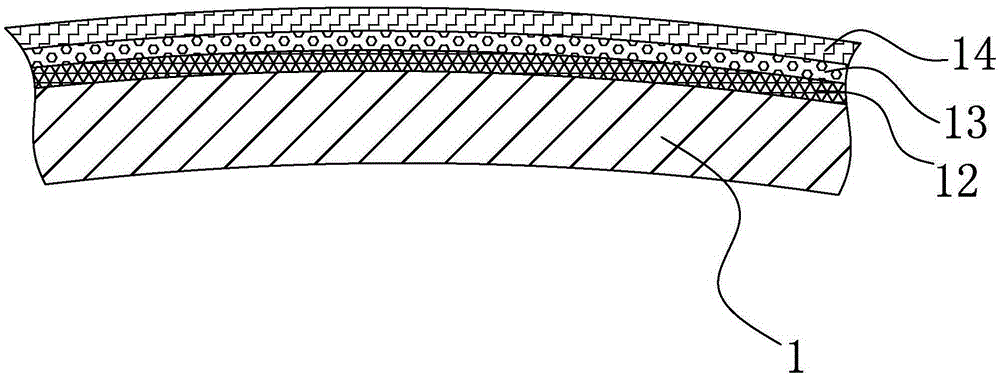

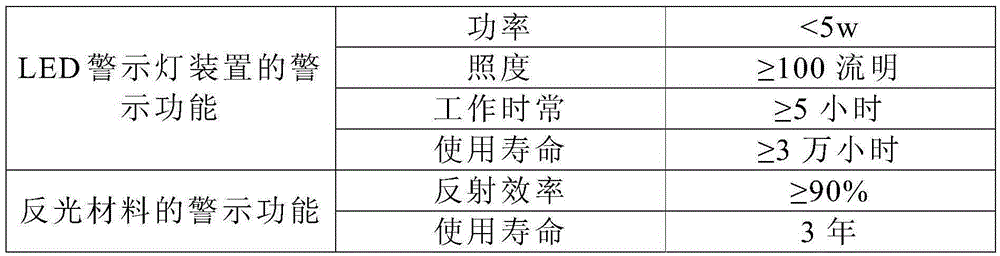

Embodiment 1

[0031] The PVC is heated to 110°C by a heating roller, and coated on the surface of the helmet shell to form a PVC bottom layer with a thickness of 0.12mm. Then place glass beads with a mesh number of 160-170 and a refractive index of 1.9 in the trough, raise the temperature of the heating roller to 90°C, and then spread them evenly on the surface of the heated PVC bottom layer through the feeding roller to form a glass microbead layer. Then use a vacuum absorber to absorb excess glass microspheres to ensure that the glass microspheres are arranged in a single layer. Then heat the KIRAM transparent light-emitting material with a thickness of 0.10mm to 130°C, and heat-bond it on the surface of the glass bead layer to form a transparent light-emitting layer. Afterwards, dry the helmet at 100°C for 30 minutes. After cooling, install a fastening belt on the helmet shell for fastening on the neck and install LED warning lights that can display various colors on the rear end of the...

Embodiment 2

[0033]The PVC is heated to 120°C by a heating roller, and coated on the surface of the helmet shell to form a PVC bottom layer with a thickness of 0.14mm. Then place glass beads with a mesh number of 170-180 and a refractive index of 2.0 in the trough, heat the heating roller to 110°C, and spread them evenly on the surface of the heated PVC bottom layer through the feeding roller to form a glass microbead layer. Then use a vacuum absorber to absorb excess glass microspheres to ensure that the glass microspheres are arranged in a single layer. Then heat the KIRAM transparent luminescent material with a thickness of 0.12mm to 140°C, and heat-bond it on the surface of the glass bead layer to form a transparent luminescent layer. Then dry the helmet at 110°C for 50 minutes. After cooling, install a fastening belt on the helmet shell for fastening on the neck and install LED warning lights in different colors on the rear end of the helmet shell. device, and the final product is a...

Embodiment 3

[0035] The PVC is heated to 140°C by a heating roller, and coated on the surface of the helmet shell to form a PVC bottom layer with a thickness of 0.16mm. Then place glass beads with a mesh number of 180-190 and a refractive index of 2.1 in the trough, raise the temperature of the heating roller to 130°C, and then evenly spread it on the surface of the heated PVC bottom layer through the feeding roller to form a glass microbead layer. Then use a vacuum absorber to absorb excess glass microspheres to ensure that the glass microspheres are arranged in a single layer. Then heat the KIRAM transparent luminescent material with a thickness of 0.13mm to 145° C., and heat seal it on the surface of the glass bead layer to form a transparent luminescent layer. Afterwards, dry the helmet at 115°C for 60 minutes. After cooling, install a fastening belt on the helmet shell for fastening on the neck and install LED warning lights in different colors on the rear end of the helmet shell. d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com