Rolling bearing lubricating oil film thickness testing device and testing method

A lubricating oil film and rolling bearing technology, applied in measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of accurate acquisition and lack of effective technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

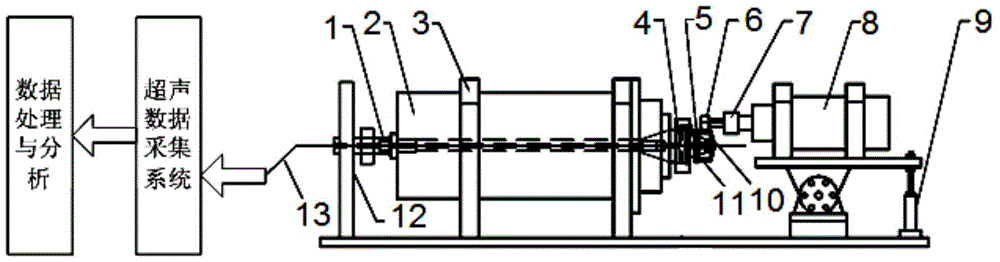

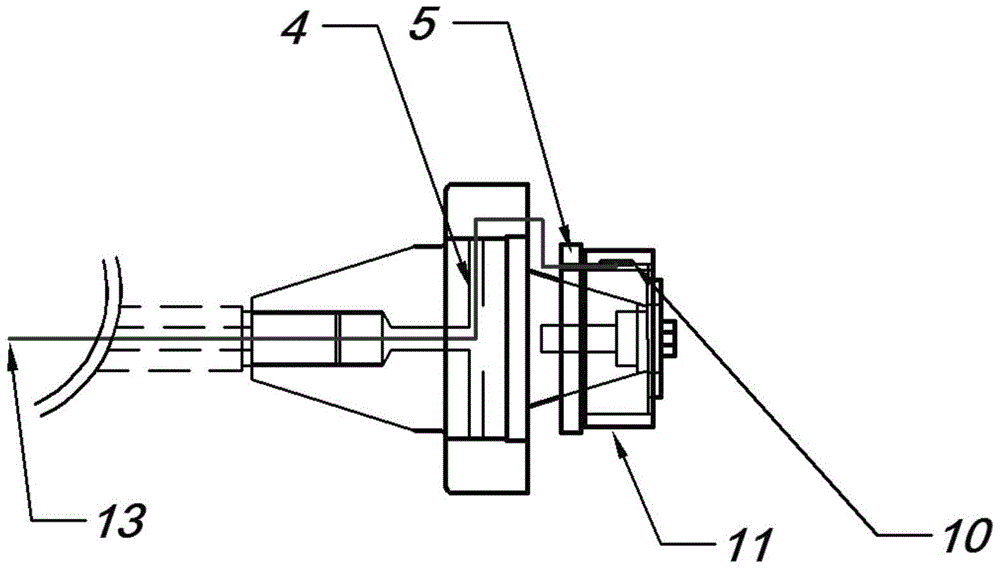

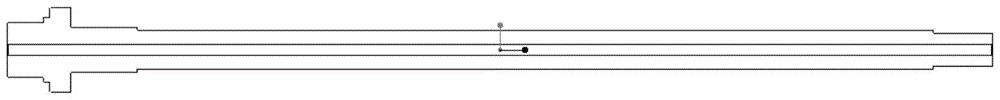

[0023] refer to figure 1 , an oil film thickness testing device for a rolling bearing slip test bench, including a low-speed electric spindle 2 axially arranged on a support 3 of the test bench, and a movable support and a force sensor 9 on the test bench relative to the low-speed electric spindle The loading mechanism is equipped with a high-speed electric spindle 8; the front end of the high-speed electric spindle is connected to the replaceable rolling element 6, and the front end of the low-speed electric spindle is connected to the ring body (inner ring or outer ring) of the bearing under test through a fixture, and the rolling element is loaded on the bearing through the loading mechanism. Radial load is applied to the ring body; displacement sensors for measuring the rotational speed are installed on the high and low speed electric spindles, which are connected to the signal of the data acquisition and processing system through the transmitter; The frequency converter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com