A detection method for the global lubricant film thickness distribution of sliding bearings

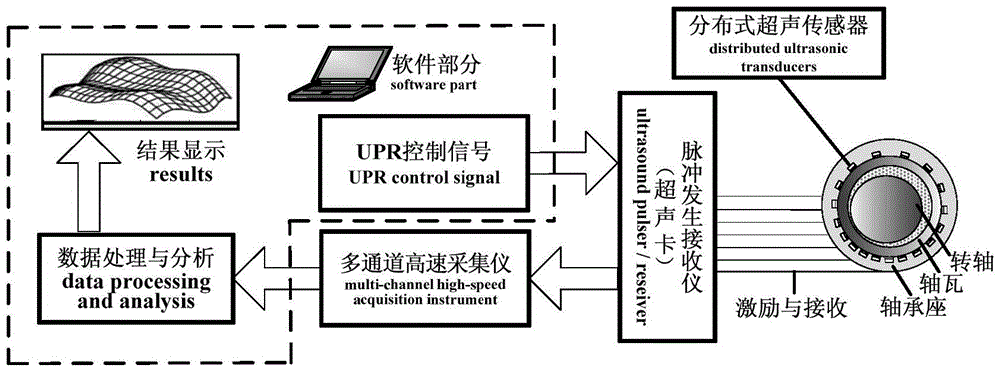

A technology for sliding bearings and detection methods, which is applied in the field of bearing lubrication, and can solve problems such as the limitation of not being able to detect the thickness of extremely thin lubricating film, the lack of a technical solution for the distribution of lubricating film thickness, and the inability to meet the requirements of obtaining the full picture information of bearing lubricating film thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

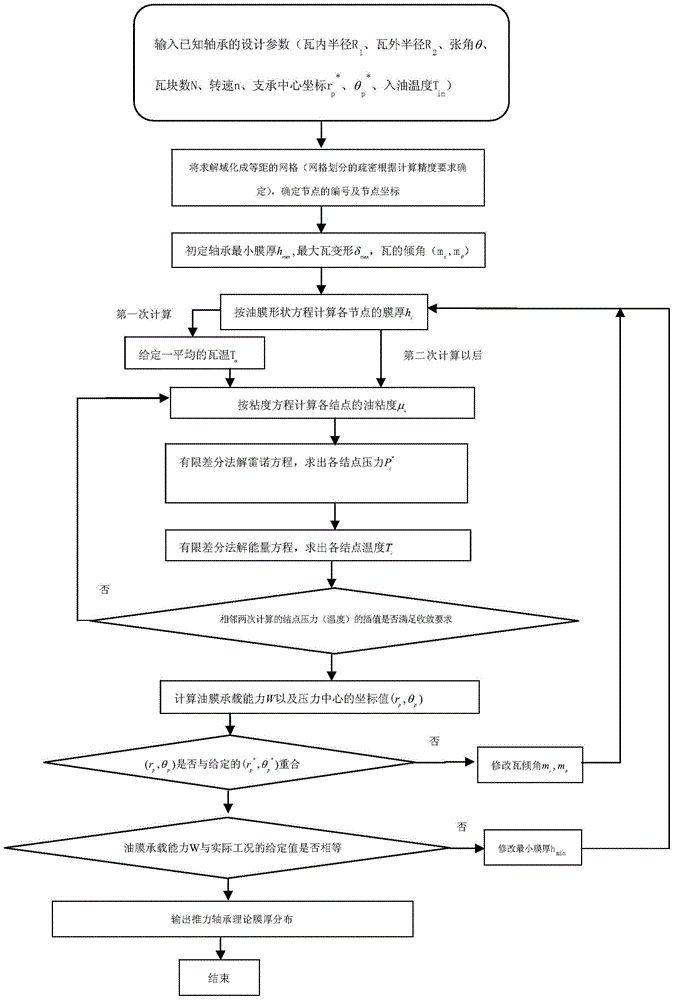

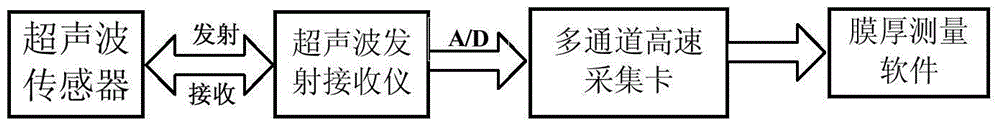

Method used

Image

Examples

Embodiment

[0092] Take a tilting pad thrust bearing test bench (such as Figure 7 ) is taken as an example to illustrate the effectiveness of the test method of the present invention. in, Figure 7 Among them, 6 is the motor, 7 is the coupling, 8 is the support bearing, 9 is the bearing end cover, 10 is the loading plate, 11 is the thrust plate, 12 is the upper seat of the bearing, 13 is the oil baffle plate, 14 is the linoleum seal, 15 It is a sleeve type pipe joint. Aiming at the characteristics of thrust bearing lubricating film distribution, a Figure 6a The distribution of measuring points is shown. Different loads are applied to the thrust disc by means of hydraulic loading, and the speed is changed in the range of 0 to 1000r / min by an adjustable speed motor. The thickness distribution of the thrust bearing's lubricating film is tested, and the lubricating film of the thrust bearing under different speeds and loads is obtained. Thick profile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com