Incoming line copper bar connecting method

A technology of incoming copper bars and connection methods, applied in the direction of busbar/line layout, etc., can solve problems such as hidden dangers of electrical safety, easy oxidation, and expansion of power outages, so as to eliminate hidden dangers of electrical safety, reduce the amount of electrical maintenance, and ensure continuous sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

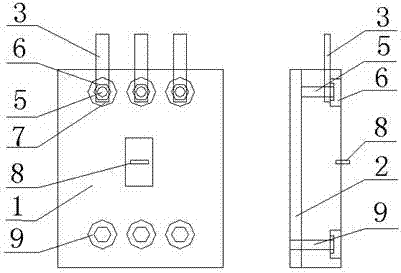

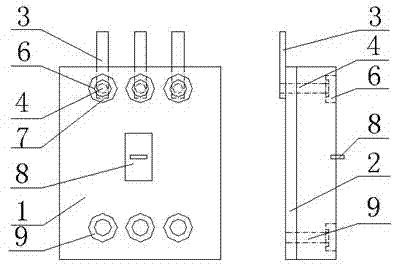

[0015] refer to figure 1 , a connection method for an incoming copper bar, including a circuit breaker body 1, the circuit breaker body 1 is installed on a base 2, an incoming copper bar 3 is fixed on the circuit breaker body 1, and the incoming copper bar 3 is a three-phase copper bar , the incoming line copper bar 3 is embedded in the front side of the upper port of the circuit breaker body 1, the lower end of the incoming line copper bar 3 is fixed by the incoming line bolt group, the incoming line bolt group is embedded in the circuit breaker body 1, and the incoming line bolt group is connected by the incoming line Stud bolt 5 and nut 6 are formed.

[0016] The upper end of the circuit breaker body 1 of this embodiment is provided with a bolt hole 7 matching the incoming bolt group; the middle of the circuit breaker body 1 is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap