A tube expander for segmental flanging of expanded tubes

A tube expander and tube expander technology, which is applied in the field of tube expanders that are convenient for segmental flanging of tube expansion, can solve the problems of easy bending and deformation of heat exchangers, and achieve the effect of fast adjustment speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

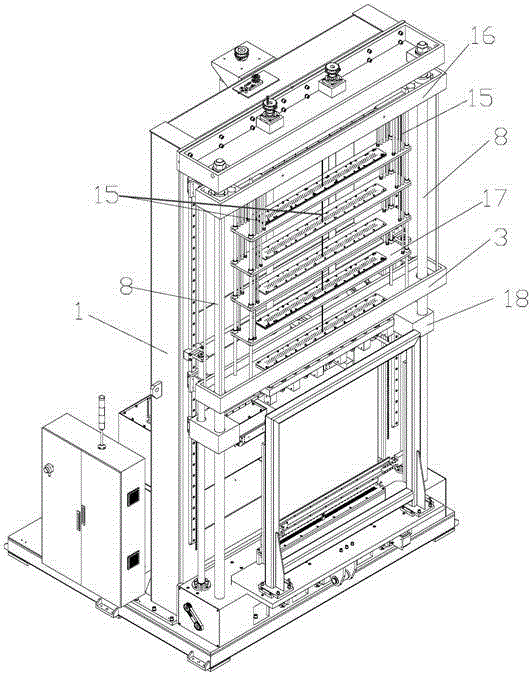

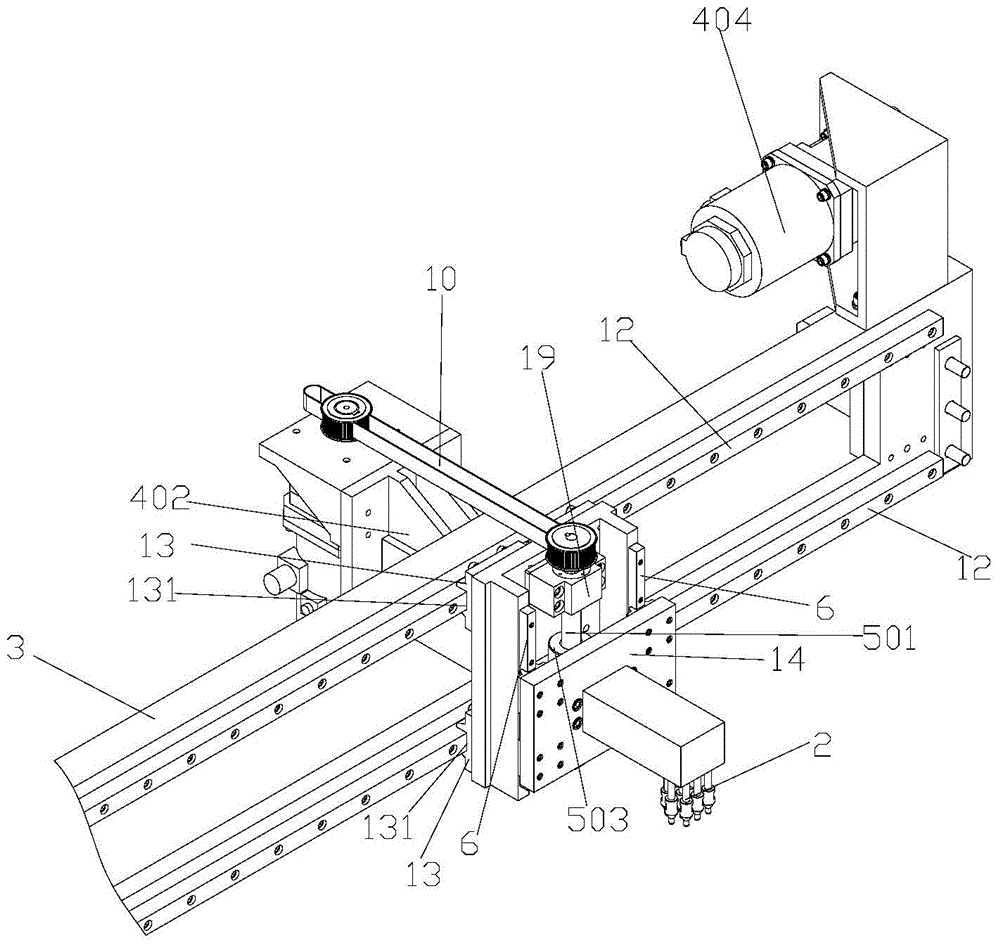

[0015] Examples such as Figures 1 to 3 As shown, a pipe expander that is convenient for segmental flanging of expanded pipes includes a frame 1 on which a group of expansion rods 15 that can slide back and forth on the frame 1 are arranged, and one end of the expansion rods 15 is fixed on On the expansion rod mold base 16, the other end is provided with a discharge seat 20, and a fixed beam 3 is arranged on the discharge seat 20; guide columns 8 are also provided on the left and right sides of the frame 1, and a stripping plate is provided under the discharge seat 20 18, is also provided with a group of expansion rod guide plate 17. The fixed beam 3 is provided with a left and right sliding plate 11 and a first driver 4 for pushing the left and right sliding plate 11 to move left and right, and the left and right sliding plate 11 is provided with an up and down sliding plate 14 and a second drive for pushing the up and down sliding plate 14 to move up and down. Part 5, on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com