Method for analyzing influence degree on reliability of numerically-controlled machine tool subsystem

A technology of numerical control machine tools and analysis methods, applied in the field of numerical control machine tools, can solve problems such as failure to consider time correlation in subsystem reliability modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

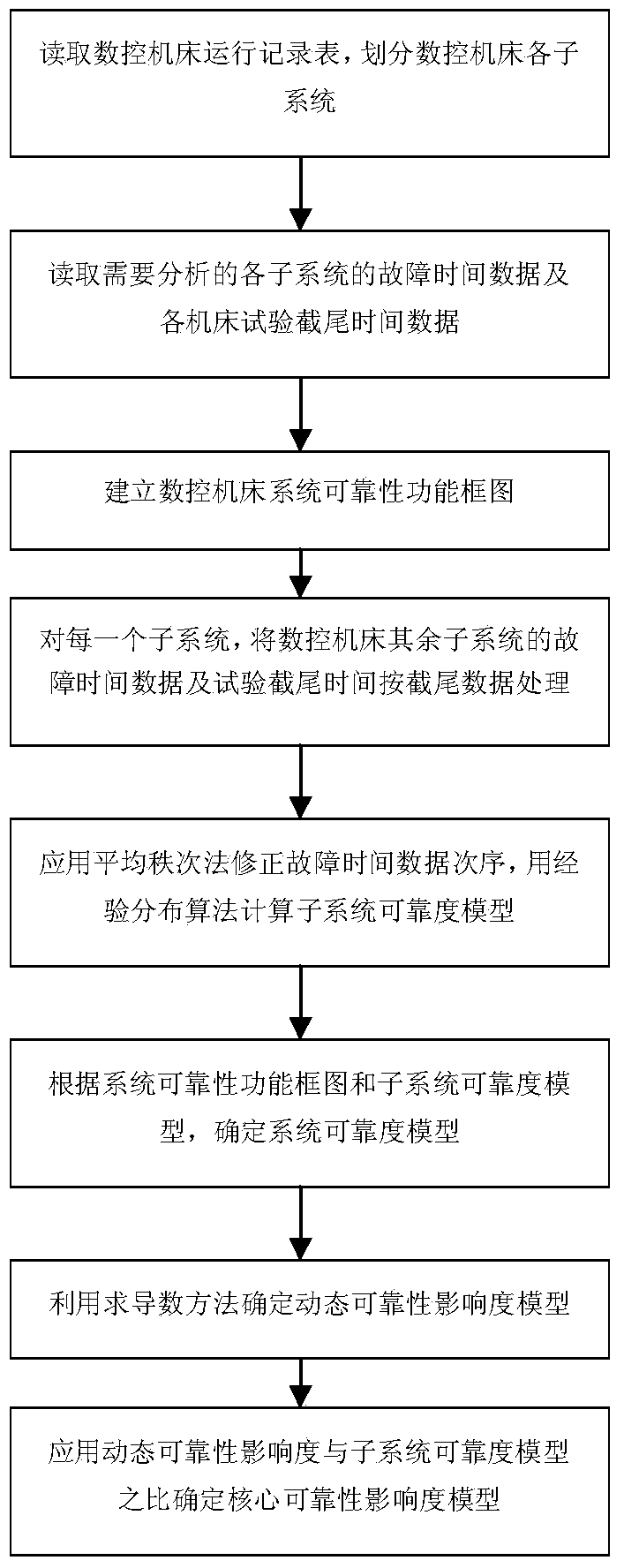

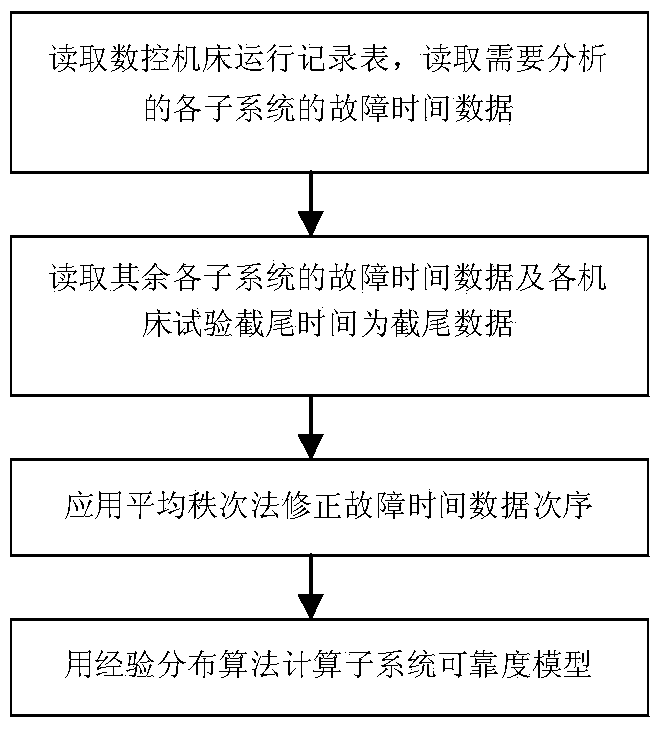

Method used

Image

Examples

Embodiment

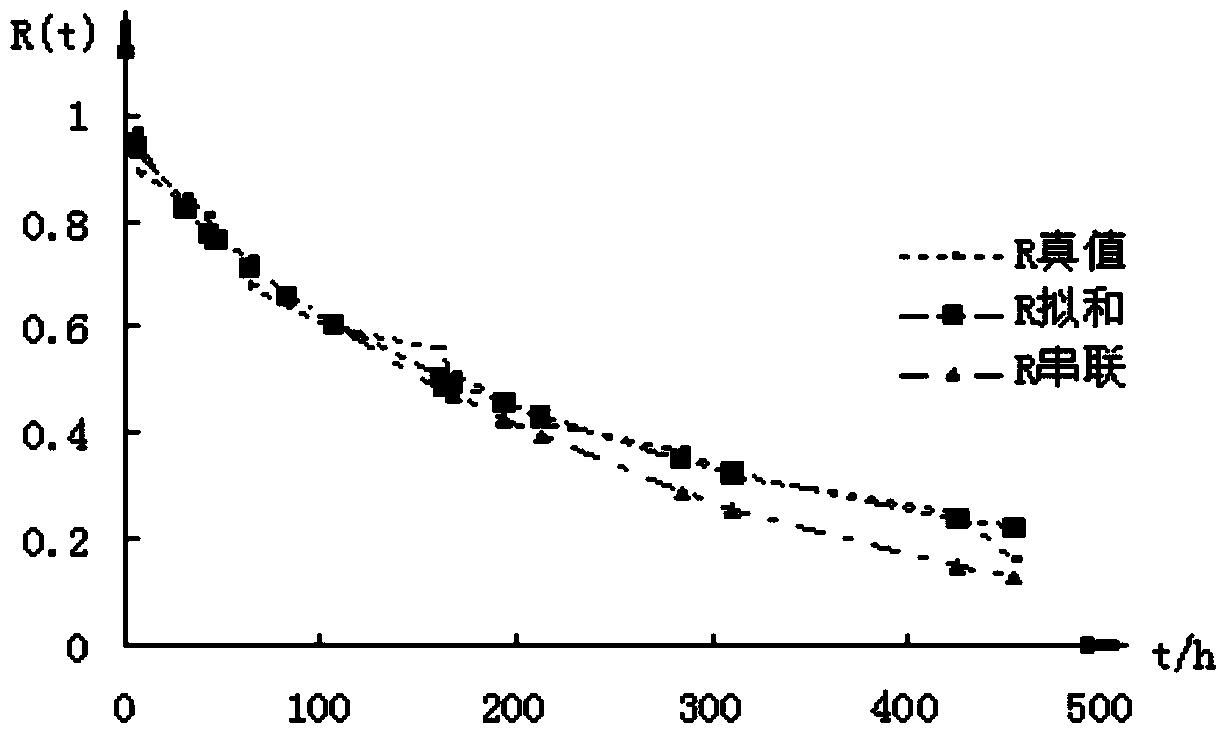

[0114] The primary task of the influence degree analysis of CNC machine tool subsystems based on time correlation is to find out the dynamic impact of subsystem failures on the overall failure of the system. This impact is constantly changing with time and is not independent. The first premise of determining the degree of influence is to establish a life distribution model that truly reflects the failure process of each subsystem and the censored time of the correlation relationship in time when the system fails. In order to determine the censored time of the time-dependent relationship of each subsystem when the CNC machine tool fails, and can correctly reflect the reliability impact between the system and the subsystem, and between the subsystems and the subsystems. If the traditional subsystem reliability analysis method is used, the failure time data of each subsystem is simply selected directly for reliability modeling, ignoring that when the machine tool is used in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com