Determination method of benzene solvent content in a kind of solvent type acrylate adhesive

A technology of acrylate and solvent content, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of affecting the detection accuracy of target compounds, affecting volatilization, accuracy and convenience to be improved, etc., to improve detection accuracy, Eliminate influences and avoid quantitatively inaccurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

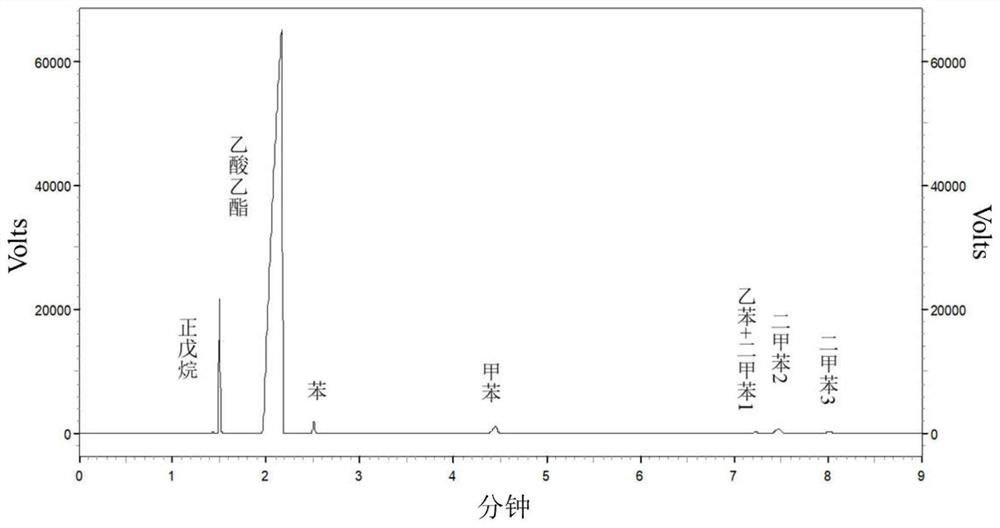

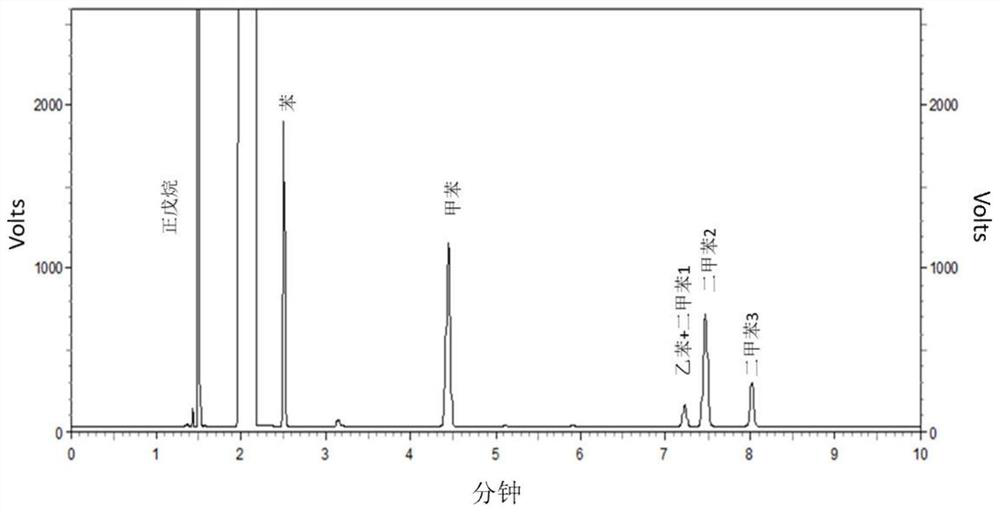

[0065] A method for determining the content of benzene solvents in a solvent-based acrylate adhesive, comprising the following steps:

[0066] a. Preparation of matrix: put an appropriate amount of acrylate adhesive to be tested in a container with a length of 100 mm, a width of 80 mm, and a height of 50 mm (or other suitable container), and the thickness of the tile is about 2 mm. Keep it at ℃ for 2 hours, then raise the temperature to 120℃ and keep it for 2 hours, keep warm and vacuumize for 1 hour, fill it with nitrogen to normal pressure, take it out, put it into a dry storage pre-filled with nitrogen protection, and cool it naturally to room temperature to prepare the matrix;

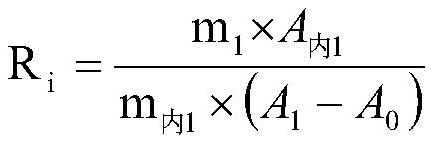

[0067] b. Preparation of internal standard standard solution: Weigh n-pentane in a 100mL volumetric flask, dilute with ethyl acetate, set the volume to the mark, and prepare 800mg / L internal standard standard solution A. Weigh benzene, Dilute toluene, ethylbenzene and xylene in a 100mL volumetric f...

Embodiment 2

[0077] A method for determining the content of benzene solvents in a solvent-based acrylate adhesive, comprising the following steps:

[0078]a. Preparation of matrix: put an appropriate amount of acrylate adhesive to be tested in a container with a length of 100 mm, a width of 80 mm, and a height of 50 mm (or other suitable container), and the thickness of the tile is about 2 mm. Keep it at ℃ for 2 hours, then raise the temperature to 120℃ and keep it for 2 hours, keep warm and vacuumize for 1 hour, fill it with nitrogen to normal pressure, take it out, put it into a dry storage pre-filled with nitrogen protection, and cool it naturally to room temperature to prepare the matrix;

[0079] b. Preparation of internal standard standard solution: Weigh n-pentane in a 100mL volumetric flask, dilute with ethyl acetate, set the volume to the mark, and configure internal standard solution A of 1200mg / L. Weigh benzene, Dilute toluene, ethylbenzene, and xylene in a 100mL volumetric flas...

Embodiment 3

[0089] A method for determining the content of benzene solvents in a solvent-based acrylate adhesive, comprising the following steps:

[0090] a. Preparation of matrix: put an appropriate amount of acrylate adhesive to be tested in a container with a length of 100 mm, a width of 80 mm, and a height of 50 mm (or other suitable container), and the thickness of the tile is about 2 mm. Keep it at ℃ for 3 hours, then raise the temperature to 115℃ and keep it for 3 hours, keep warm and vacuumize for 1 hour, fill it with nitrogen to normal pressure, take it out, put it into a dry storage pre-filled with nitrogen protection, and cool it naturally to room temperature to prepare the matrix;

[0091] b. Preparation of internal standard standard solution: Weigh n-pentane in a 100mL volumetric flask, dilute with ethyl acetate, set the volume to the mark, and configure internal standard solution A of 1000 mg / L. Weigh benzene, Dilute toluene, ethylbenzene and xylene in a 100mL volumetric fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com