A kind of preparation method of nb3al superconducting joint

A technology of superconducting joints and joint tubes, applied in the direction of connecting contact materials, connections, electrical components, etc., can solve problems such as unstable quality, complex and harsh process conditions, etc., and achieve the effect of reducing joint resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

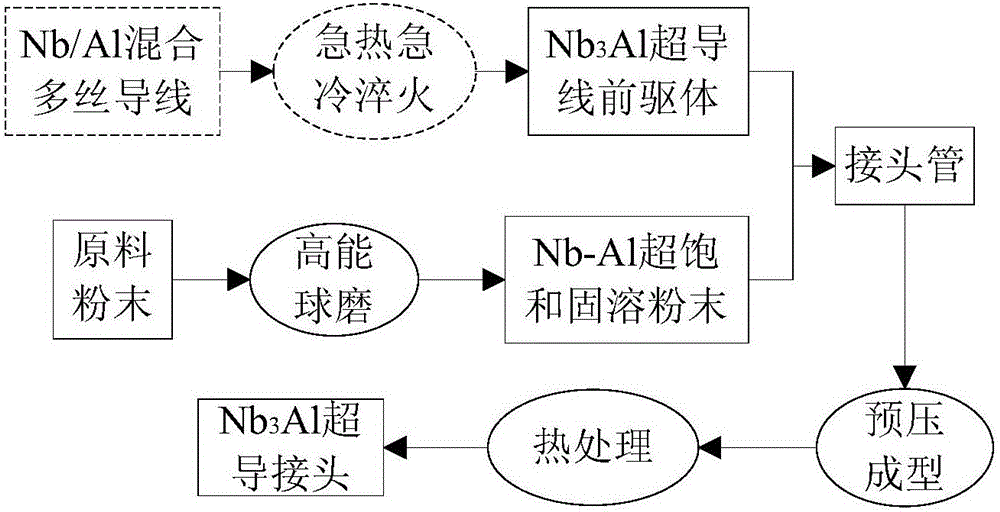

Method used

Image

Examples

Embodiment 1

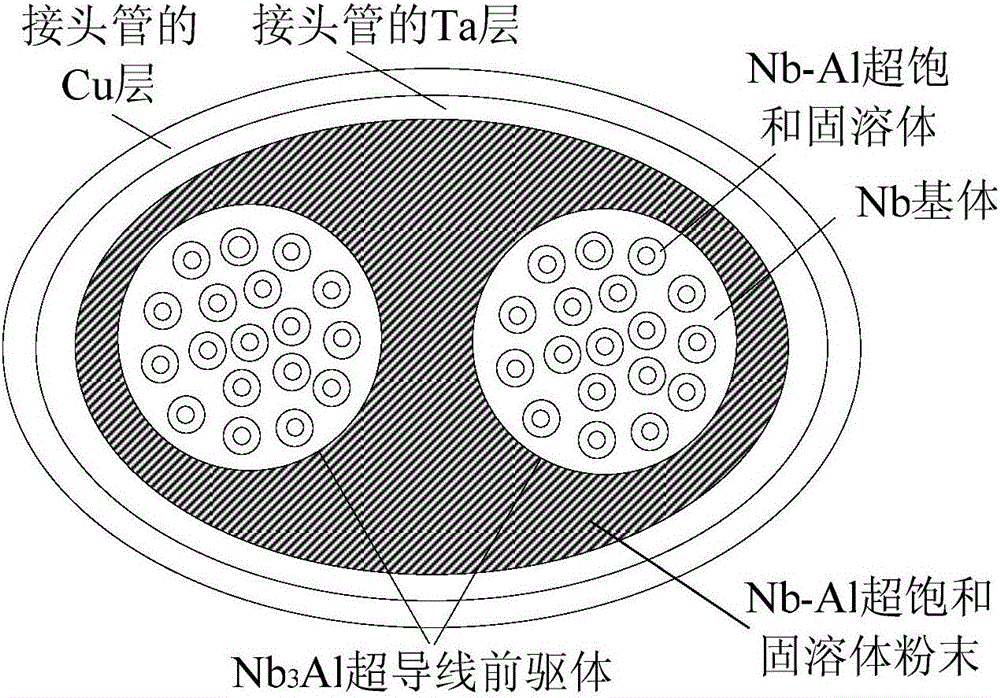

[0038] Preparation of Nb 3 Al superconducting joints. First, pure Nb powder and pure Al powder are mixed together according to the atomic number ratio of 3:1, the powder particle size is 20 microns, and the powder mass after mixing is 200 grams in total; the pure Nb powder, pure Al powder, and 5 grams of sodium stearate powder and 3000 grams of agate material grinding balls are put into the agate material ball mill jar of planetary ball mill together and carry out high-energy ball milling. The high-energy ball milling process is carried out in a vacuum environment, and the vacuum degree is less than or equal to 1×10 -2 Pa. Figure 6 In order to prepare high energy ball milled Nb by planetary ball milling 3 Schematic diagram of the principle of Al supersaturated solid solution powder. After the ball milling is completed, put the ball mill jar into a vacuum glove box, take out the ball-milled Nb-Al supersaturated solid solution powder in a vacuum environment, and dry and sto...

Embodiment 2

[0041] Preparation of Nb 3 Al superconducting joints. First mix Nb-20at% Al alloy powder and pure Al powder together, so that the atomic ratio of Nb and Al in the two powders reaches 3:1. Both powders have a particle size of 200 microns and a total mass of 200 grams; put Nb-20at% Al alloy powder and pure Al powder together with 5 grams of dispersant sodium stearate powder and 3000 grams of agate material grinding balls and stir High-energy ball milling was carried out in the agate material ball milling tank of the type ball mill. Figure 7 In order to prepare high energy ball milled Nb by stirring ball milling 3 Schematic diagram of the principle of Al supersaturated solid solution powder. After the ball milling, put the ball mill jar into a vacuum glove box, take out the ball milled Nb-Al supersaturated solid solution powder, vacuum seal it and store it dry. Remove Nb 3 Shell material of Al superconducting wire precursor. In the vacuum glove box, take the Nb-Al supersat...

Embodiment 3

[0044] Preparation of Nb 3 Al superconducting joints. First, pure Nb powder and pure Al powder are mixed together according to the atomic number ratio of 3:1, the particle size of the powder is 100 microns, and the total mass is 200 grams; the pure Nb powder, pure Al powder, and dispersant stearic acid 5 grams of sodium powder and 3000 grams of corundum material grinding balls are put into the corundum material ball mill jar of the vibratory ball mill together for high-energy ball milling. Figure 8 In order to prepare high energy ball milled Nb by vibratory ball milling 3 Schematic diagram of the principle of Al supersaturated solid solution powder. After the ball milling, put the ball mill jar into a vacuum glove box, take out the ball milled Nb-Al supersaturated solid solution powder, vacuum seal it and store it dry. Remove Nb 3 Shell material of Al superconducting wire precursor. In the vacuum glove box, take the Nb-Al supersaturated solid solution powder and the supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com