Transmission assembly of fuel tricycle

A technology for tricycles and transmissions, applied in vehicle gearboxes, vehicle parts, gear transmissions, etc., can solve problems affecting product quality and easily damaged gears, and achieve the effects of solving serious gear damage, improving product quality, and ingenious ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

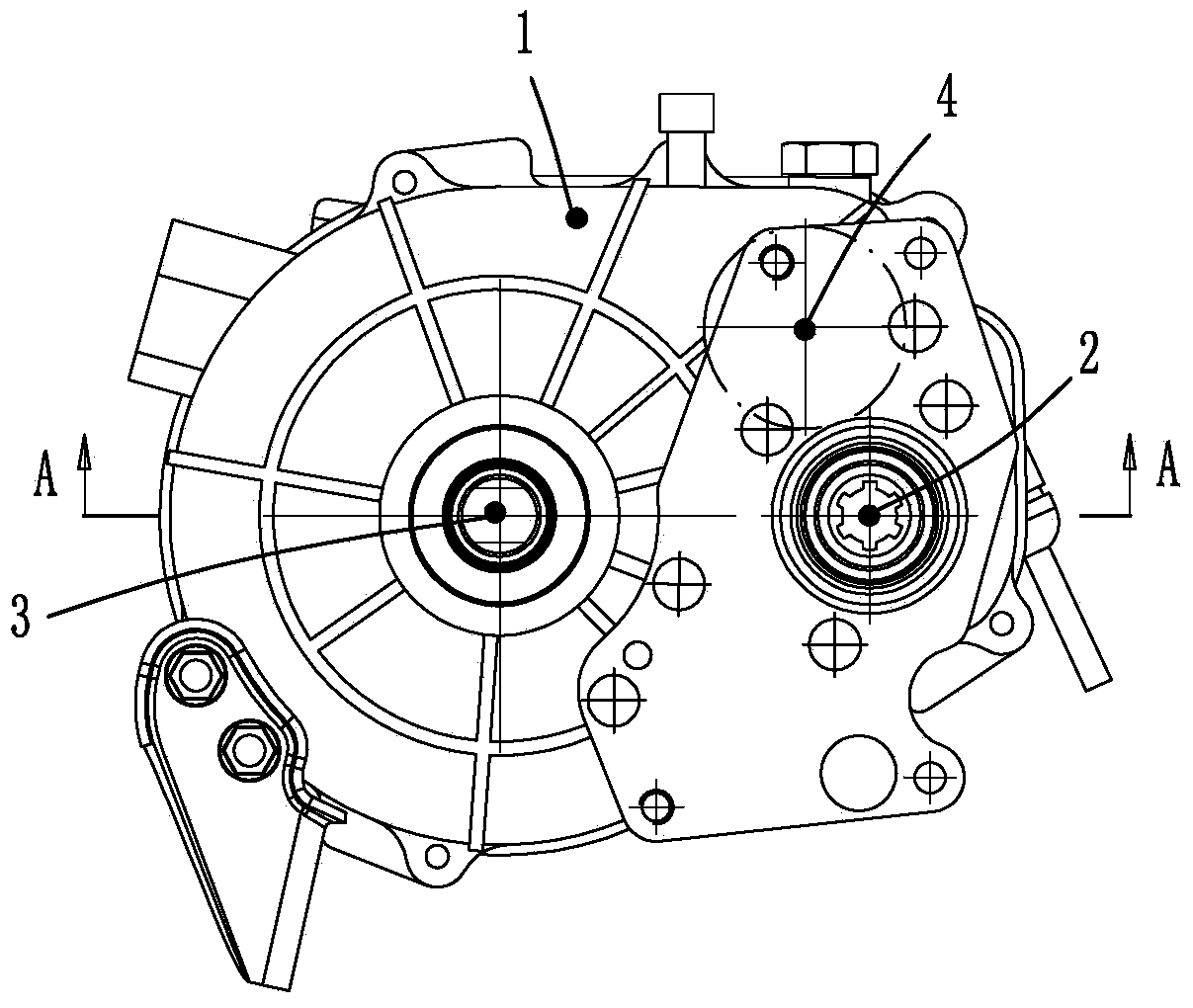

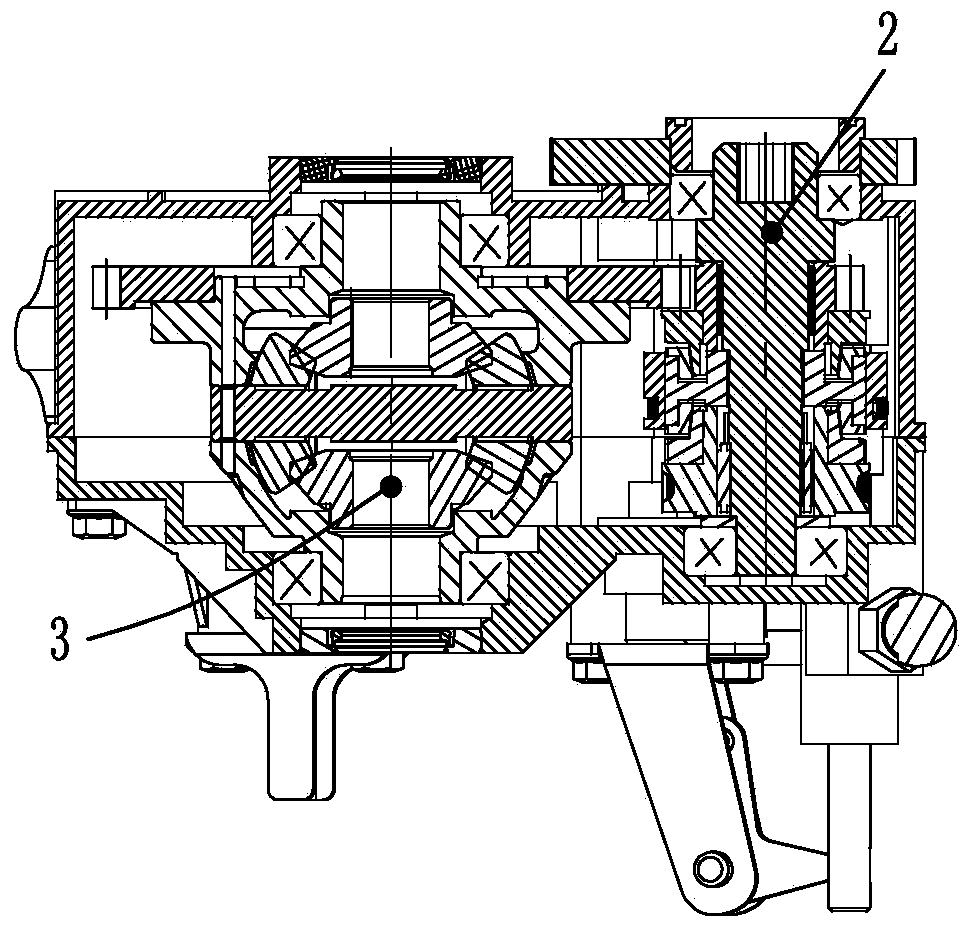

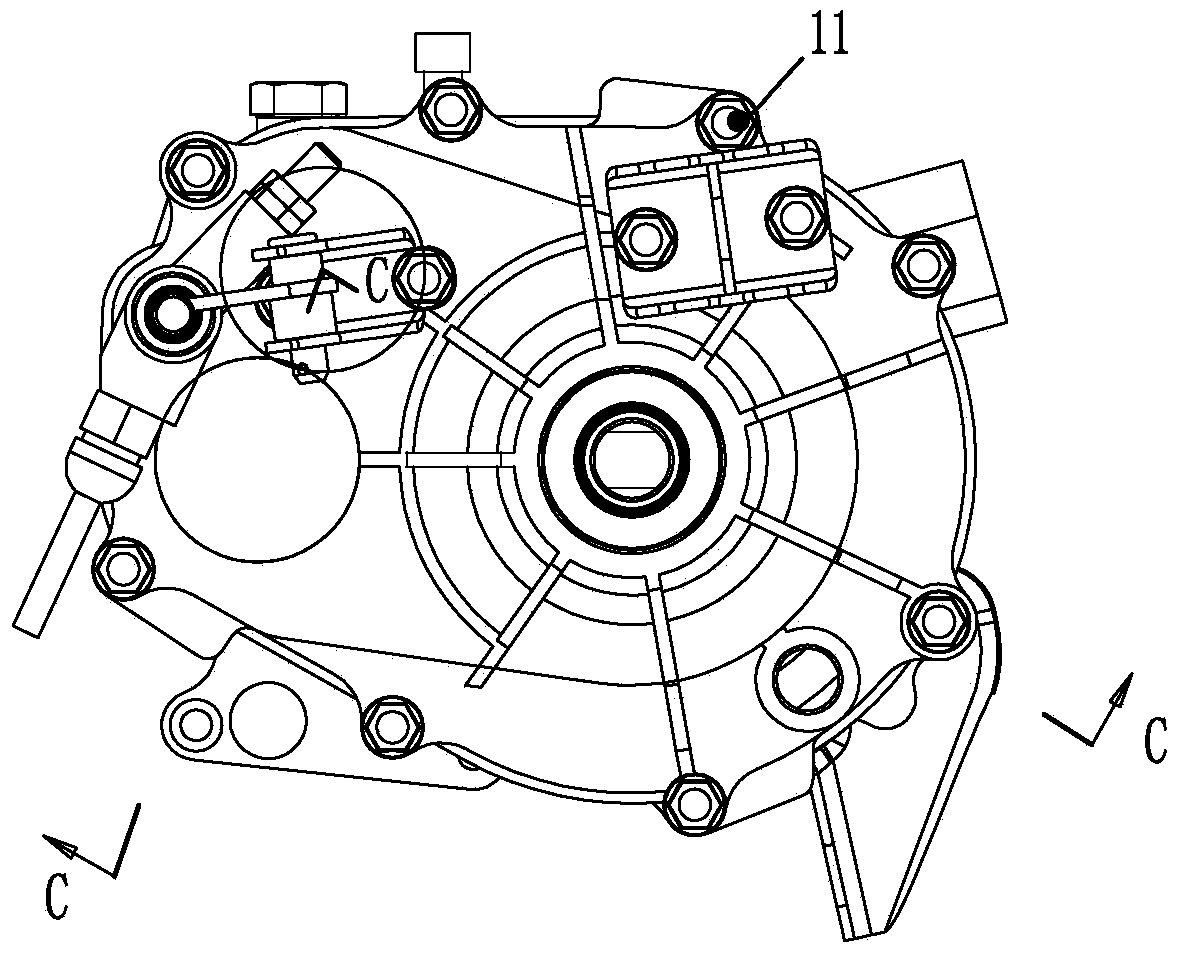

[0012] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0013] combine figure 1 —— Figure 4 The fuel tricycle transmission assembly shown is composed of a transmission housing 1, and an input shaft 2, an output shaft 3, a reverse gear idler shaft 4, a forward driving gear 5, a synchronizer 6, and a reverse gear installed in the transmission housing 1. Drive gear 7, first gear 8, second gear 9, final reduction gear 10, some bolts 11, shifting fork 12 etc. are formed.

[0014] On the input shaft 2, a forward gear 5, a synchronizer 6 and a reverse gear 7 are sequentially sleeved, and the synchronizer 6 is located between the forward gear 5 and the reverse gear 7. The synchronizer 6 is slidingly connected to the input shaft 2, and the forward drive gear 5 and the reverse drive gear 7 are fixedly connected to the input shaft 2. The synchronizer 6 can move along the input shaft 2 under the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com