Tricycle transmission

A technology for transmissions and tricycles, applied to instruments, vehicle parts, gear transmissions, etc., can solve the problems of unreasonable layout of the outer wall of the transmission, affecting the compactness of the overall structure, low sensitivity and accuracy, etc., to solve serious gear damage and overall The effect of compact and reasonable structure and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

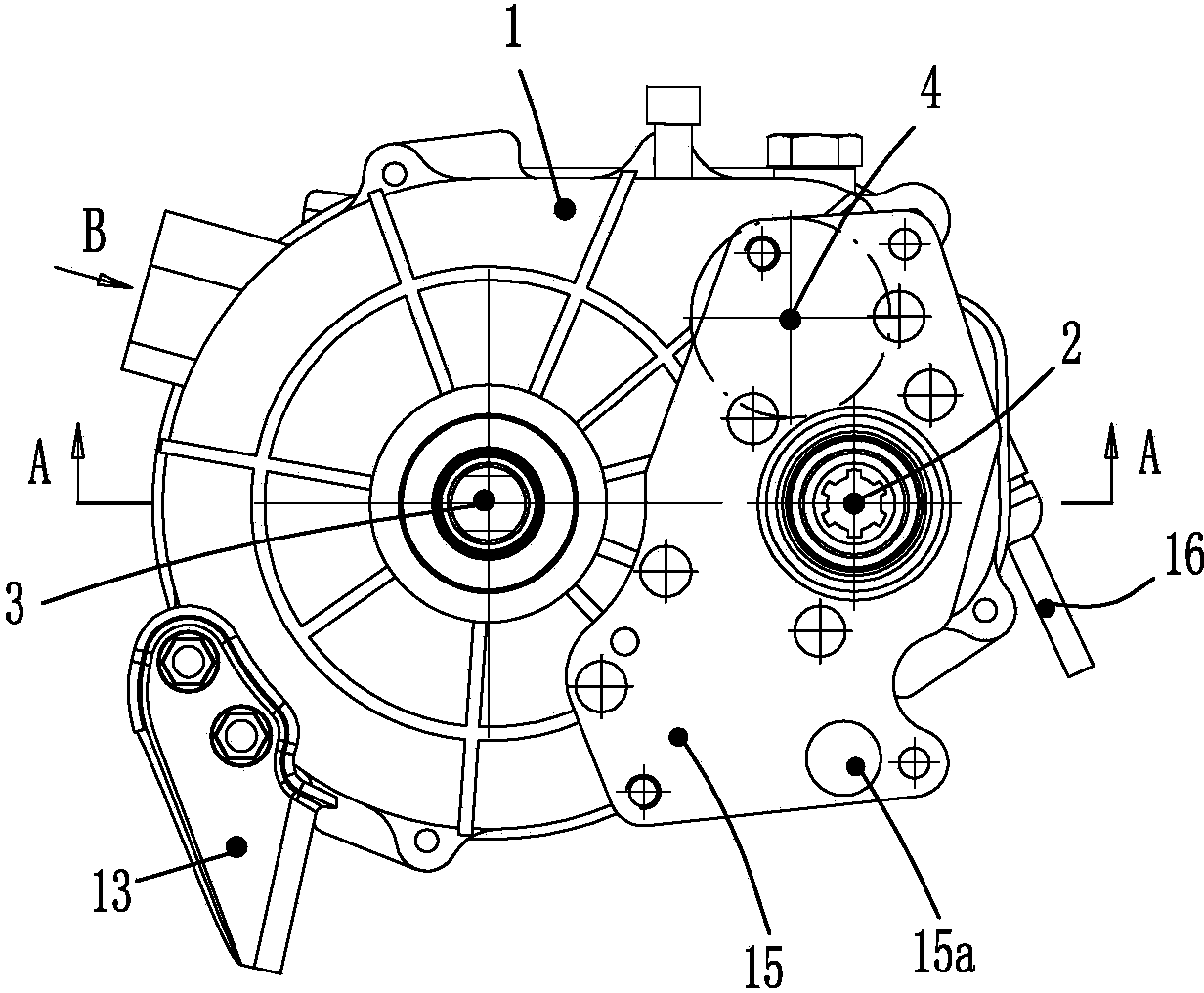

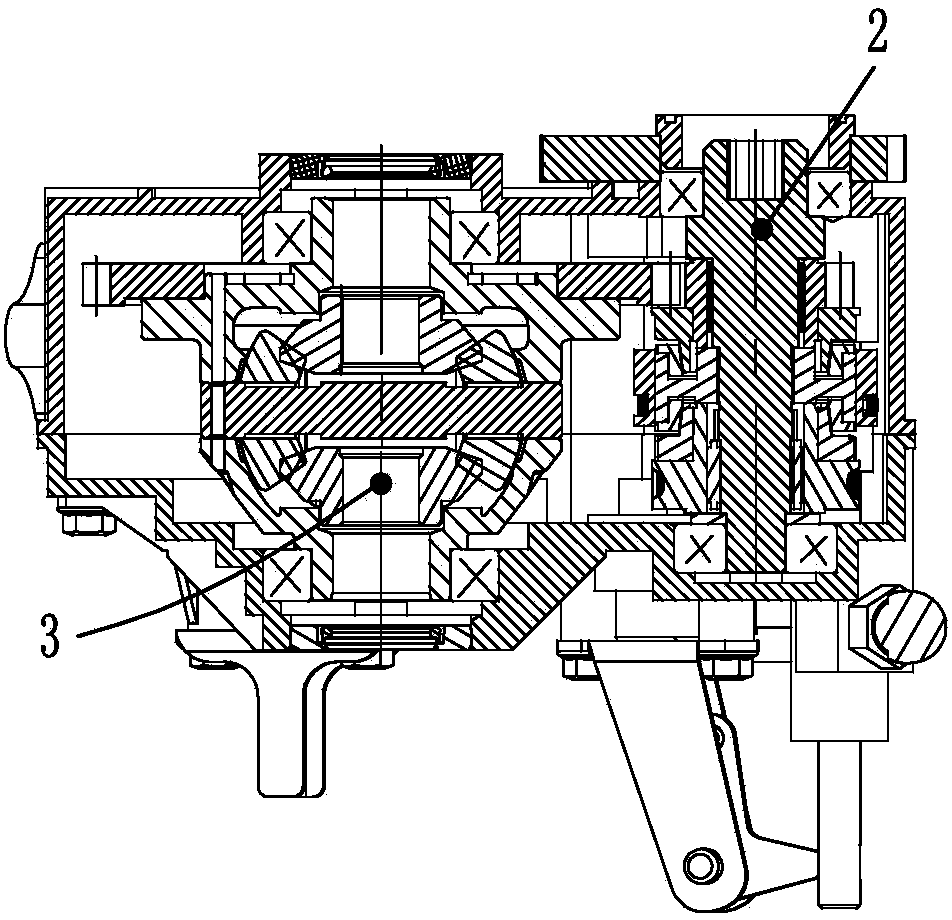

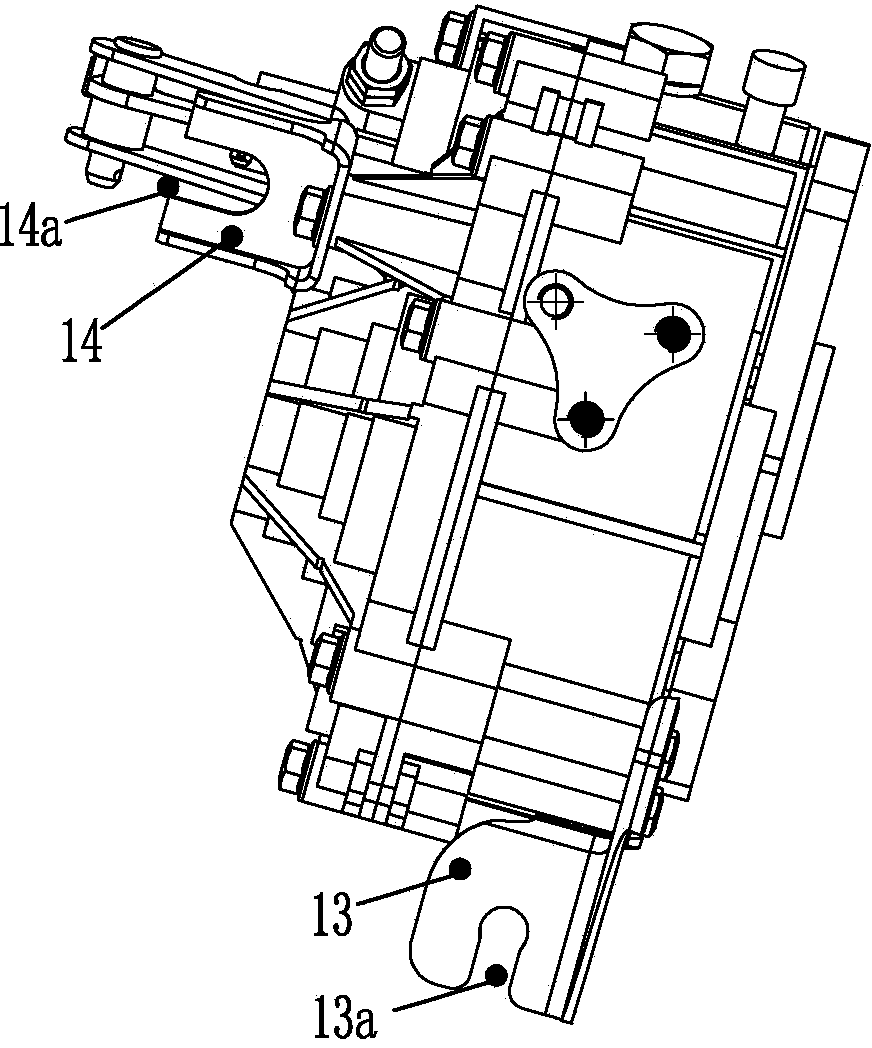

[0018] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0019] combine figure 1 —— Figure 5 The tricycle transmission shown is composed of a transmission housing 1, an input shaft 2, an output shaft 3, a reverse gear idler shaft 4, a forward gear driving gear 5, a synchronizer 6, a reverse gear driving gear 7, a first gear 8, and a second gear 9. Main reduction gear 10, several bolts 11, shift fork 12, engine zipper bracket 13, gear shift zipper bracket 14, engine mounting plate 15, reverse light switch 16, etc. Input shaft 2, output shaft 3, reverse gear idler shaft 4, forward gear driving gear 5, synchronizer 6, reverse gear driving gear 7, first gear 8, second gear 9, main reduction gear 10, shift fork 12 Installed in the transmission housing 1 , the engine zipper bracket 13 , the gear shift zipper bracket 14 , the engine mounting plate 15 , and the reverse light switch 16 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com