Pipeline blockage positioning method and device

A positioning method and pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as high operating costs, heavy workload, and affecting oil transportation tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the present invention will be further described: this kind is made up of following steps to the localization method of pipeline blockage:

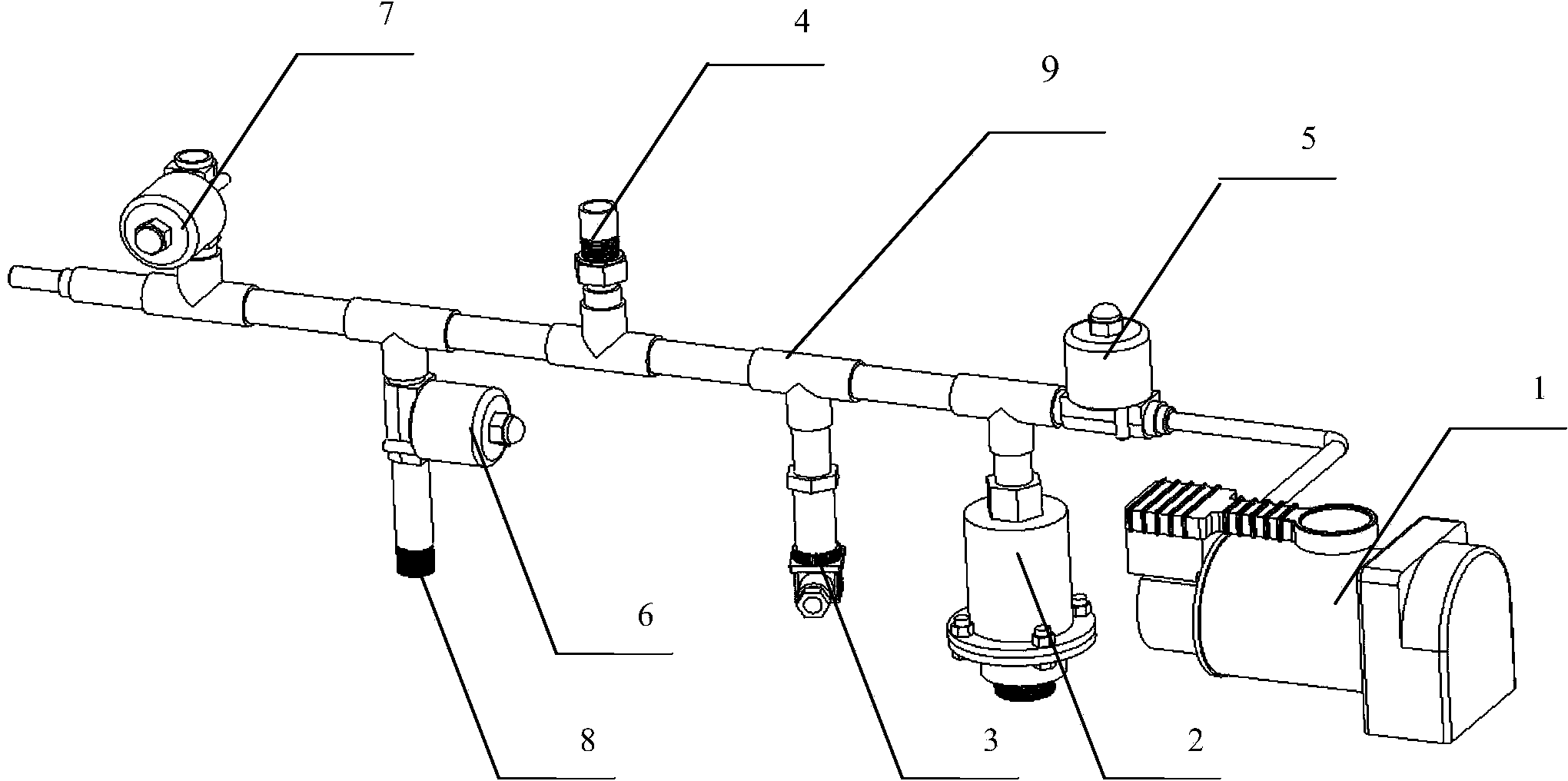

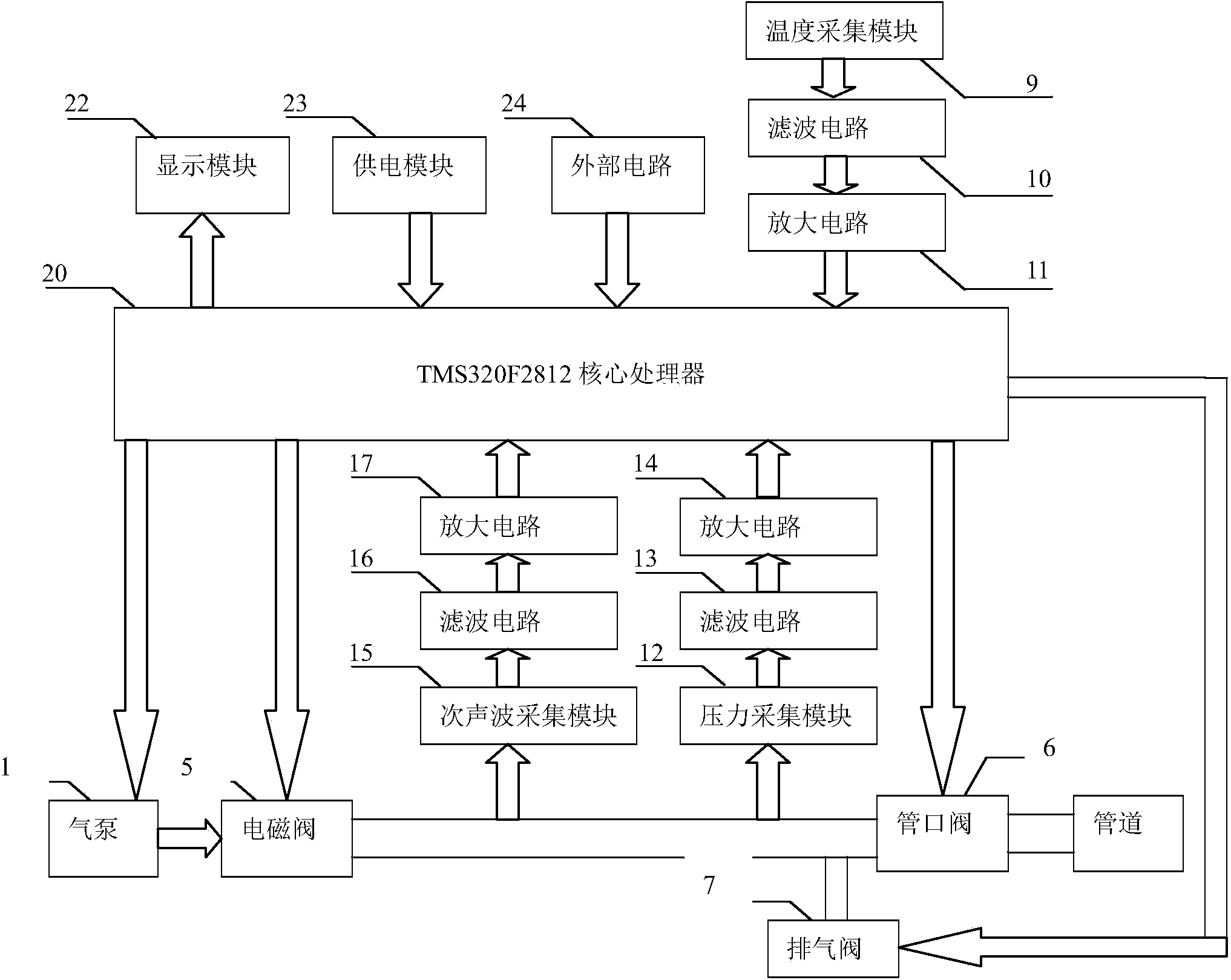

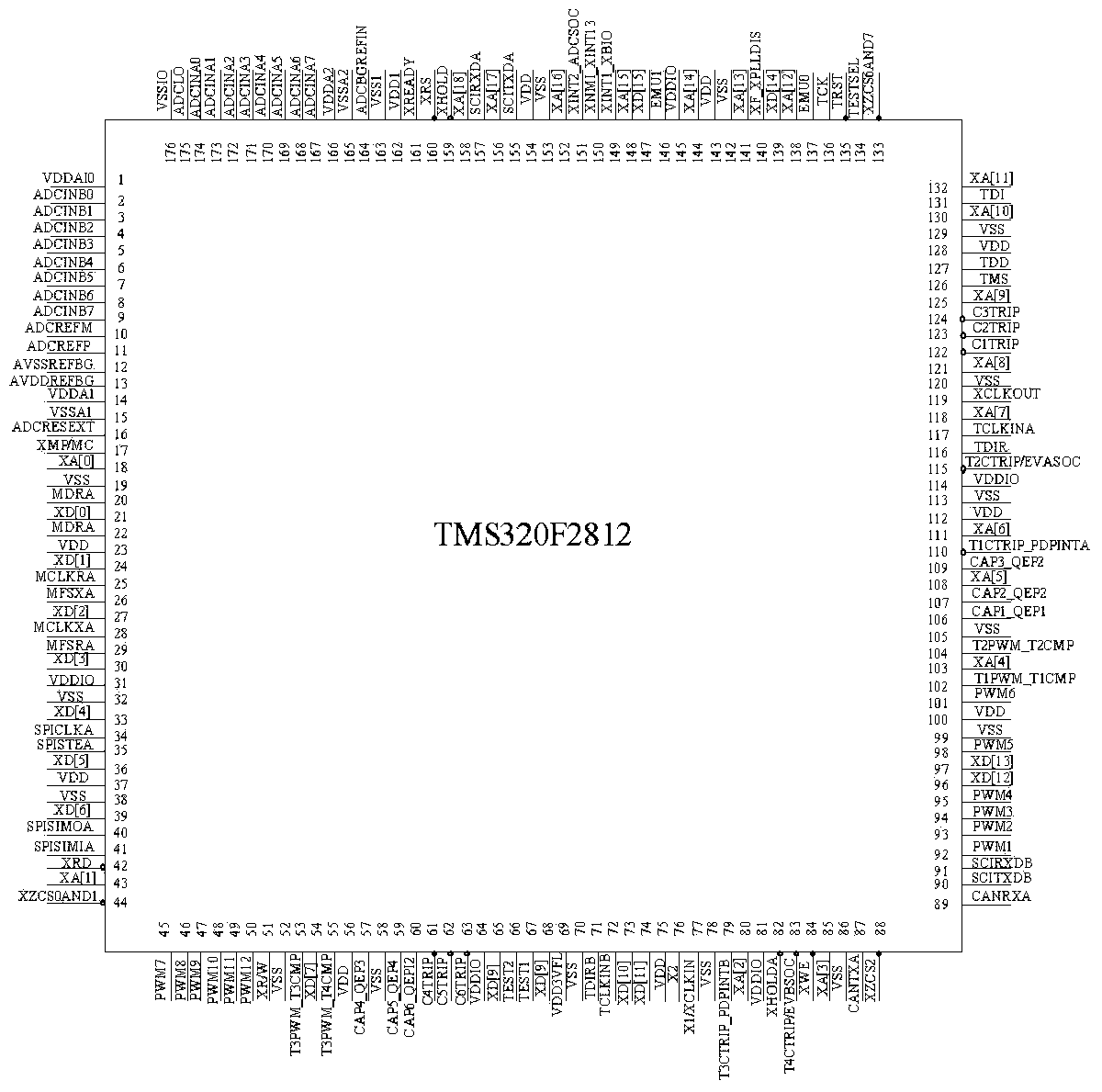

[0055] A detection device consisting of a core control board, a compressed air pump, an infrasonic sensor, a pressure sensor, a temperature sensor, a solenoid valve for controlling the release of sound waves, a nozzle valve, an exhaust valve and connecting pipes is installed on the pipeline to be tested;

[0056] Use the pressure sensor to collect the pressure value in the pipeline to be tested and the connecting pipeline. If the pressure value is greater than 0.2Mpa, control the exhaust valve in the detection device to open to release the gas in the pipeline;

[0057] Under the condition that the pressure meets the requirements, control the compressed air pump of the detection device to inflate automatically, the air pressure of each inflated air is 0.7MPa, and the gas volume is 35L pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com