Movable testing frame structure

A technology of activity detection and frame structure, which is applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve the problems affecting the placement of workpieces, and achieve the effect of convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

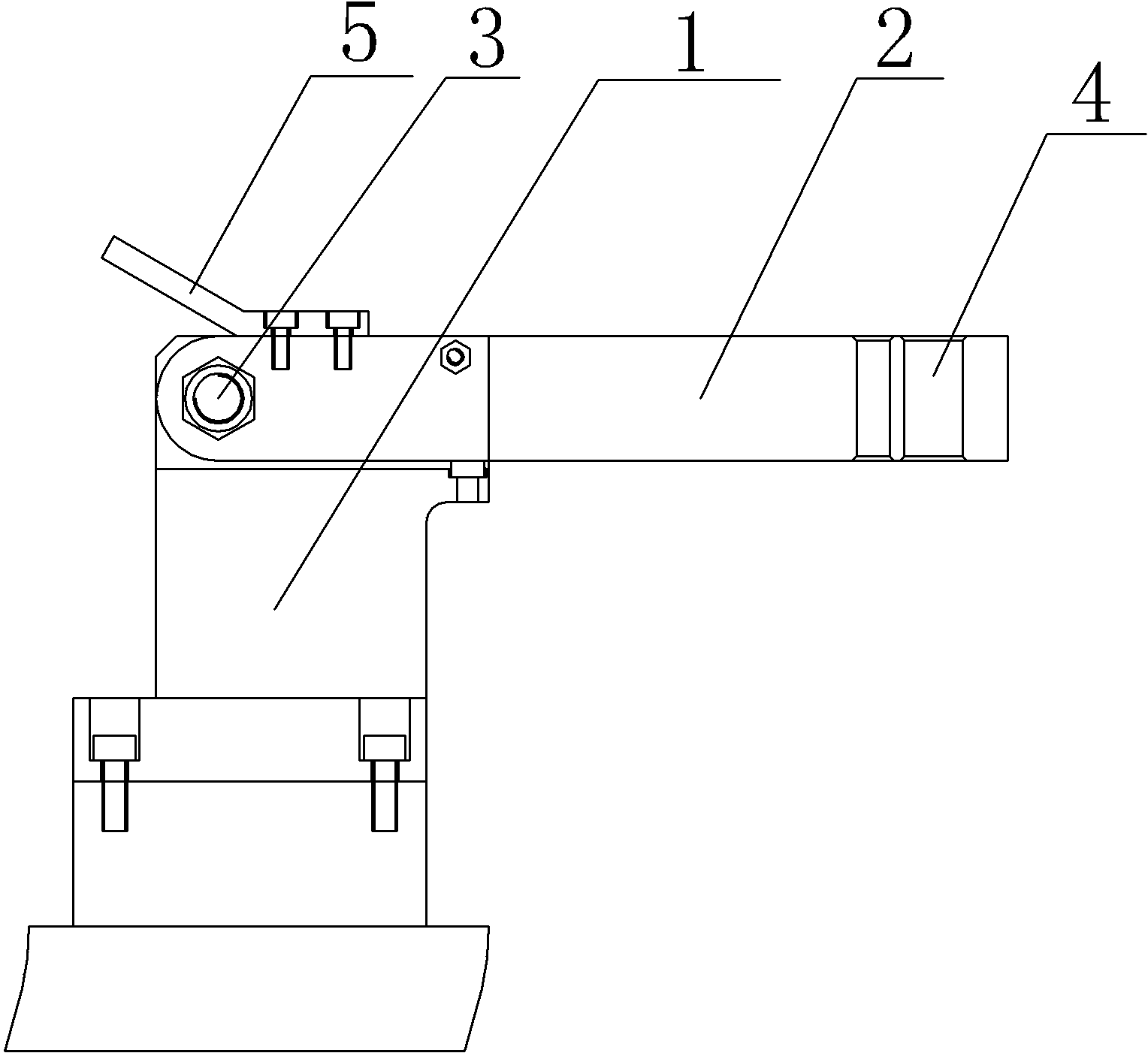

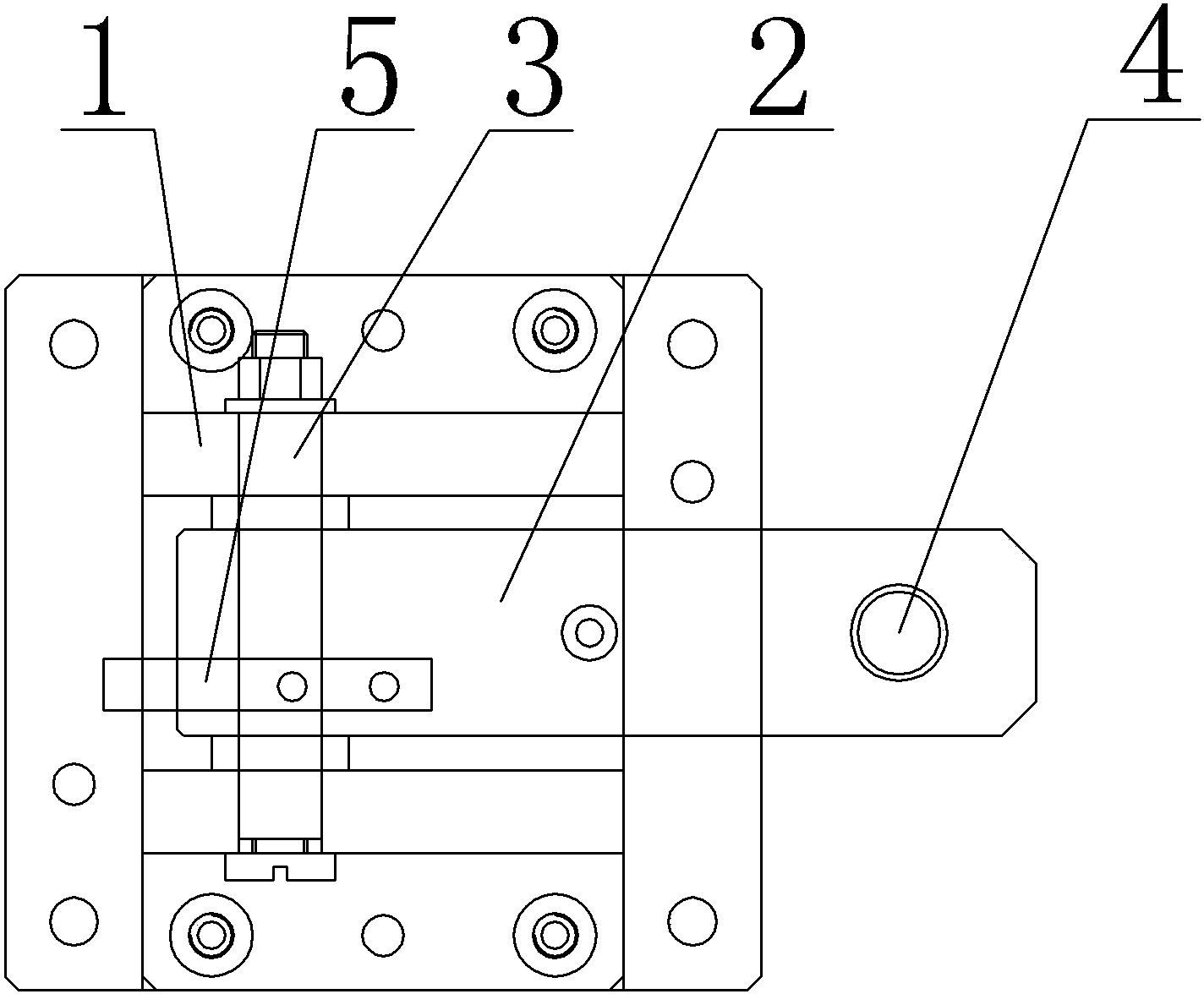

[0009] See figure 1 , figure 2 , a movable detection frame structure, which includes a bracket 1, a flap 2 is arranged on the bracket 1, the flap 2 is connected to the bracket 1 through a pin shaft 3, a detection hole 4 is arranged on the flap 2, and a detection hole 4 is arranged on the flap 2 Tool (not shown in the figure), the limit block 5 is set on the flap 2, since the flap can be rotated through the pin shaft, the flip of the flap can effectively avoid the influence of the detection frame on the placement of the workpiece, and facilitate the convenient placement of the workpiece .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com