Convenient and safe punching machine for aluminum veneer production

An aluminum veneer and safe technology, which is applied in the field of convenient and safe punching machines for aluminum veneer production, can solve problems such as increasing the labor intensity of workers, and achieve the effects of easy processing, scientific and reasonable structure, and avoiding position offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

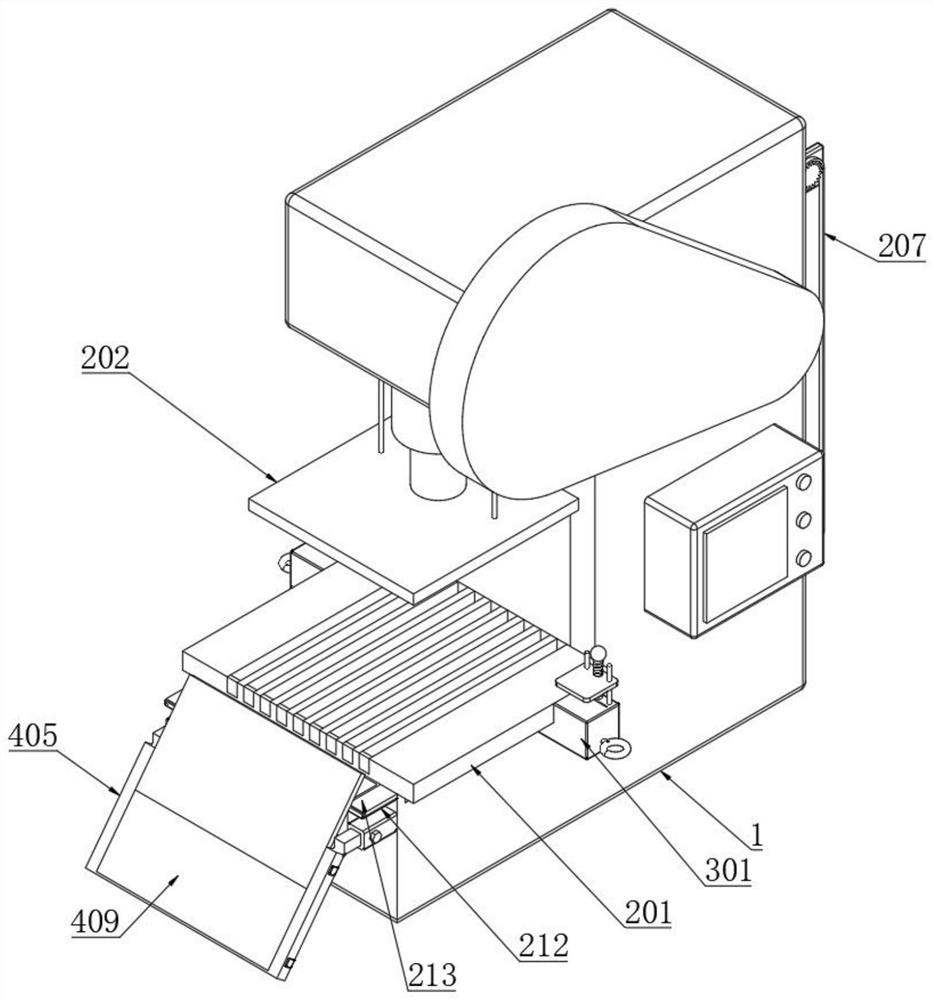

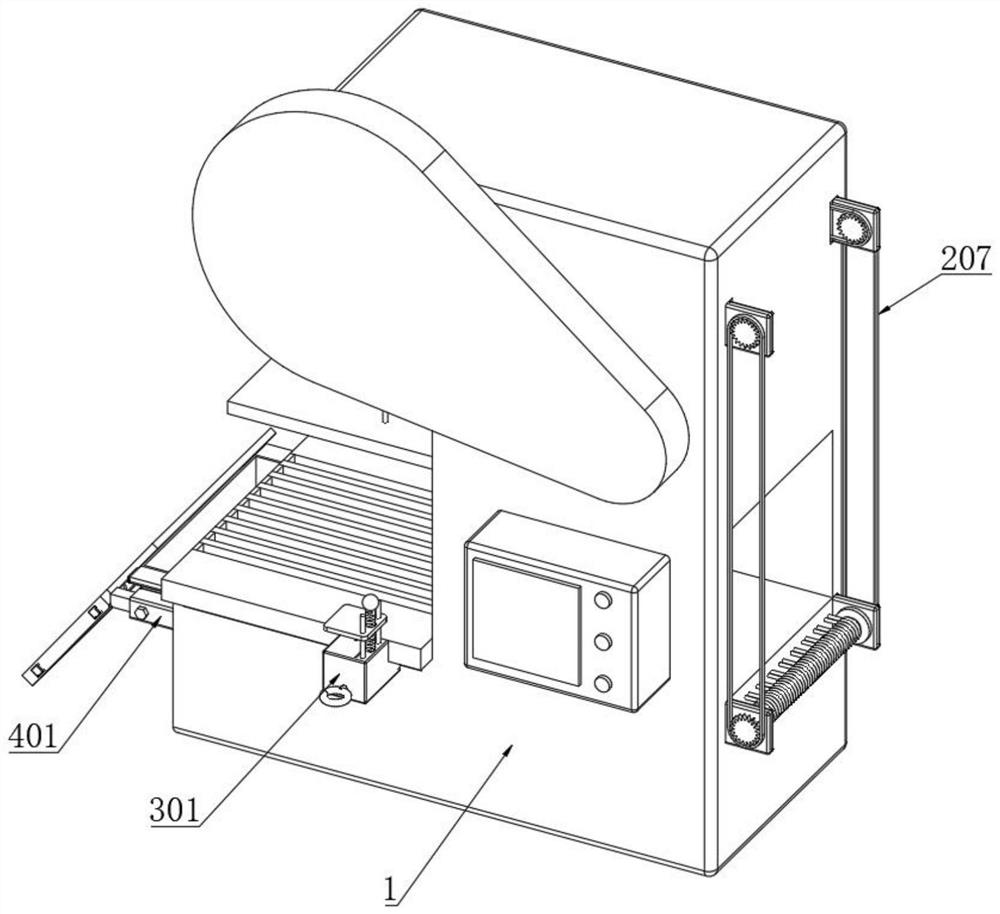

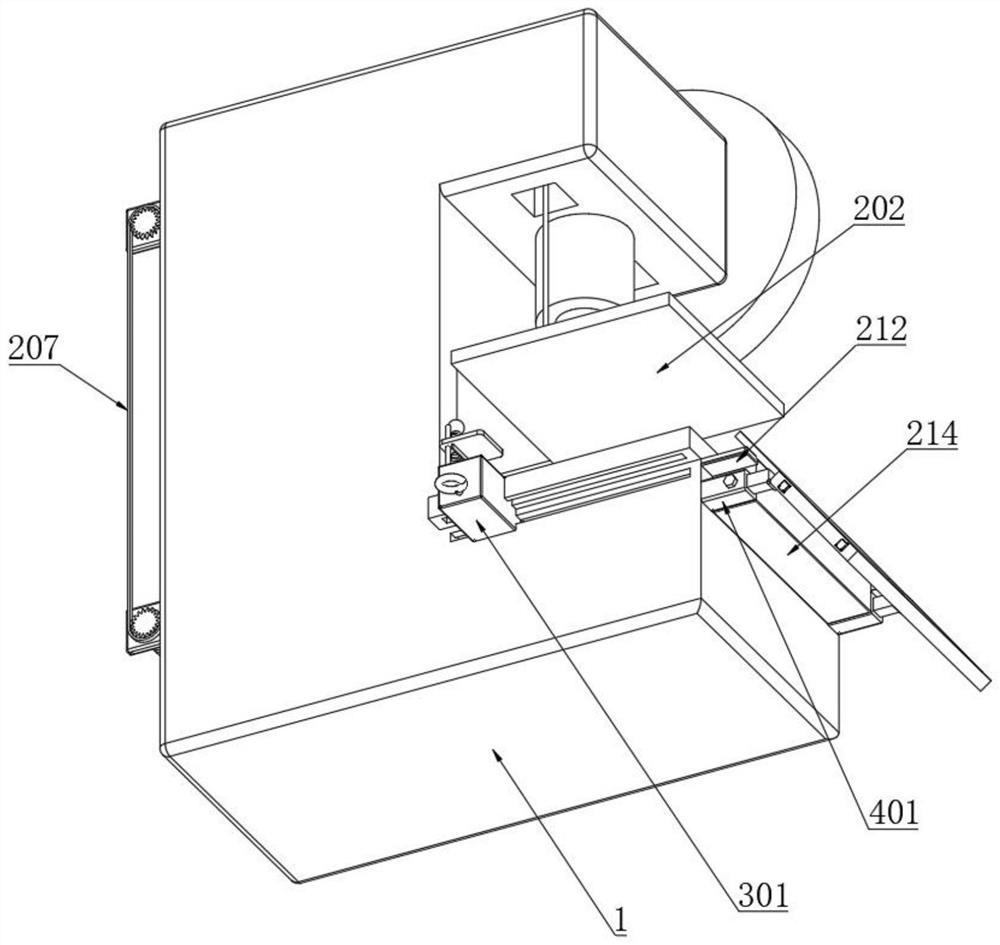

[0050] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a convenient and safe punching machine for aluminum veneer production, including a fixed seat 1, and a linkage cleaning component 2 is installed on the inner side of the fixed seat 1, through the connecting rope 204, the fixed plate 205, the transmission gear 206 and the drive chain 207 can make the cleaning rod 211 move with the movement of the punching plate 202, so that the cleaning rod 211 can clean up the remaining impurities inside the punching table 201 after each punching plate 202 is punched, reducing the work. Difficulty for personnel to clean up impurities;

[0051] Adjustment and positioning components 3 are installed on both sides of the fixing seat 1, through the cooperation of the threaded column 302, the clamping plate 303 and the limit column 304, it is convenient for the staff to fix the position of the materials with different thicknesses placed on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com