Foldable-type welding manipulator

A welding manipulator and foldable technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large size, and achieve the effects of easy storage and transportation, cost saving and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

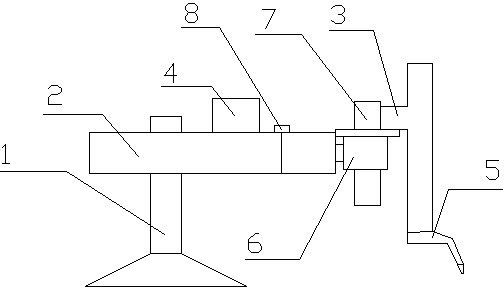

[0009] Such as figure 1 It is a structural diagram of a foldable welding manipulator. A foldable welding manipulator includes a support frame 1, a large rocker arm 2, a small rocker arm 3, a controller 4 and a welding gun 5. The large rocker arm 2 is movably connected to the On the vertical axis of the support frame 1, the controller 4 is fixed on the large rocker arm 2, the top of the small rocker arm 3 is provided with a welding gun 5, the top of the large rocker arm 2 is provided with a bearing 6, and the end of the small rocker arm 3 is provided with The movable shaft 7 and the small rocker arm 3 are movably connected with the large rocker arm 2 by placing the movable shaft 7 in the bearing 6, and the front half of the large rocker arm 2 is fixedly connected with the rear half using a buckle 8.

[0010] When storage or transportation is required, the buckle 8 only needs to be opened, and then the large rocker arm 3 is folded up. The welding manipulator can be folded freely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com