Hollow-out flexible printed circuit board with ACP conductive adhesive being printed thereon

A technology of flexible printing and conductive adhesive, which is applied in the direction of printed circuit, printed circuit manufacturing, printed circuit components, etc. It can solve the problems of hard boards that cannot be bent, defective products, AG wire breakage, etc., and achieve regular distribution of conductive particles, The effect of eliminating potential safety hazards and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

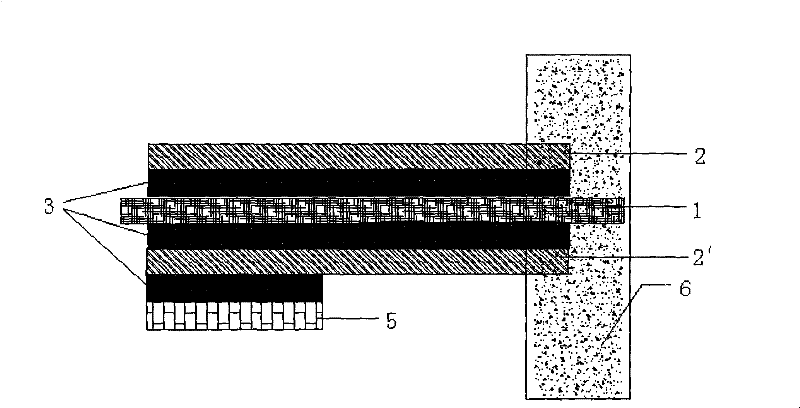

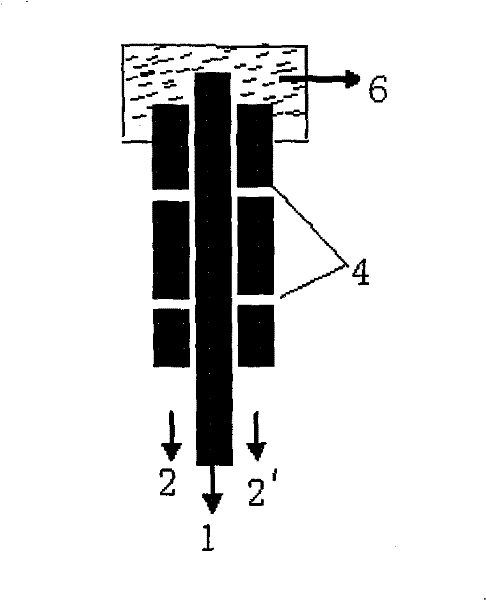

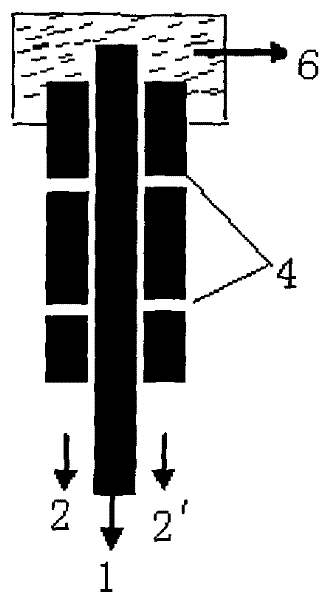

[0024] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention; figure 2 It is a schematic side view of an embodiment of the present invention.

[0025] Such as figure 1 with figure 2 As shown, a hollow flexible printed circuit board printed with ACP conductive glue includes a substrate 1 and a circuit formed thereon, the substrate 1 is pure copper foil, and the bottom surface of the substrate 1 is provided with a bottom surface with a solder joint opening 4 PI cover film, the surface of the substrate 1 has a pattern forming a circuit, and the top of the figure is provided with a surface PI cover film 2 that only exposes the upper solder joint opening 4, and the surface PI cover film 2 can also be provided with a PI cover film reinforcement 5, Both surface and bottom PI cover films 2, 2' and PI cover film reinforcement 5 contain Adhesive adhesive 3.

[0026] The above-mentioned surface PI covering film 2 , bottom surface PI c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com